Exhibit 99.2

Sustainability Report 2021 Stevanato Group

Exhibit 99.2

Sustainability Report 2021 Stevanato Group

Table of contents Letter to Stakeholders IV Methodological note VII STEVANATO GROUP 9 1.1 Highlights 10 1.2 Story and evolution 12 1.3 Mission, Vision and Values 24 1.4 The company structure and main corporate functions 27 1.5 Ethics, integrity and compliance 34 STEVANATO GROUP AND SUSTAINABILITY 37 2.1 Approach to sustainability 38 2.2 Certifications and awards 45 2.3 Participation in organizations and associations 49 ECONOMIC SUSTAINABILITY 52 3.1 Stakeholder value creation 53 3.2 Key financial results 55 RESEARCH, DEVELOPMENT, INNOVATION AND PRODUCT RESPONSIBILITY 60 4.1 Stevanato Group products, technologies and services 61 4.1.1 Biopharmaceutical and Diagnostic solutions 64 4.1.2 Engineering 70 1 2 3 4

Sustainability Report—2021 4.2 R&D and Innovation 71 4.2.1 R&D for Drug containment solutions (DCS) 72 4.2.2 R&D on Drug Delivery Systems (DDS) 73 4.2.3 R&D on Engineering 74 4.2.4 Analytical Services 78 4.3 Product quality and responsibility 80 ATTENTION TO HUMAN CAPITAL 83 5.1 Stevanato Group’s human resources5 84 5.2 Employee management and development 92 5.3 Occupational Health & Safety 100 SUPPLY CHAIN RESPONSIBILITY 108 6.1 Responsible supply chain & procurement 109 ATTENTION TO THE ENVIRONMENT 117 7.1 Stevanato Group’s commitment to the environment 118 7.2 Energy Consumption and GHG Emissions 120 7.3 Water management 124 7.4 Waste management 129 THE LINK WITH THE TERRITORY 133 8.1 Local communities engagement 134 Topic Boundaries 138 GRI Content Index 139 Independent Audit Report 144 5 6 7 8

Sustainability Report—2021 Letter to Stakeholders Giovanni Stevanato had a dream and a vision. He wanted to create world-class glass manufacturing activities in Piom-bino Dese, Italy, and set a standard of excellence in the industry. Seventy years ago, we took over his legacy, proudly building a global manufacturing enterprise with an international team of dedicated professionals driven by his same passion and desire to keep learning and improving. In 2021, we joined the New York Stock Exchange and began the next chapter in our storied history. The listing will further strengthen our integrated offerings, increase Stevanato’s market penetration across our business segments and accelerate our growth. We are proud of what we have accomplished and excited for our future as a listed company. As a global operation with 16 sites around the world, we foster a culture that values diversity and respects individual contributions that spark innovation, leadership and exceptional performance. Our strength comes from working together as One Team towards a common goal: enhance the integrity of medicines to help people live a better life. To do so, we work alongside customers, partners and the scientific community to find effective, high-quality solutions to new problems, pushing the limits of knowledge further and further while always keeping the customer and patient at the center of what we do. Along the way, our Values and Guiding Principles provide a framework for our ethical-social responsibilities and ensure our accountability. As with any organization, we have been through some challenging times. There were moments when we modified our plans and changed direction in order to meet the needs of our stakeholders. In those instances, we evaluated, adjusted and altered our approach, reacting to, or sometimes even anticipating, market demands. But we held steadfastly to our belief that the best way to make a difference is by transforming an obstacle into an opportunity for growth. We are now a leading global provider of drug containment, delivery and diagnostic solutions to the biopharma-ceutical and life sciences industries. We deliver an integrated, end-to-end portfolio of products, processes and services that address customer needs across the entire drug life cycle at each of the development, clinical and commercial stages. Our core capabilities in scientific research and development, technical innovation and engineering excellence are central to our ability to offer integrated, value-added solutions to our clients. Through our investments in research and development and with our global reach, we have secured a leadership position in the drug development and delivery value chain. Over our 70-year history, we have earned a leading reputation for high quality and reliability, enabling us to become the partner of choice for more than 700 companies globally, including 41 of the top 50 pharmaceutical companies (which comprise all of the top 15), and eight of the top ten in-vitro diagnostic companies, as measured by 2020 revenue data collected by Global Data. We also serve 15 of the top 20 biotechnology companies by market capitalization in the NASDAQ Biotechnology Index and over 100 biotechnology customers in total. IV |

Sustainability Report—2021 Our priority is to provide flexible, integrated, end-to-end solutions that preserve the integrity of pharmaceutical products, enabling our customers to deliver safe and effective drug products to patients quickly and efficiently while reducing the time to market, total cost of ownership (i.e., logistic, storage and personnel costs) and supply chain risk. We achieve this by developing our products in partnership with our customers and leveraging our scientific research, technical expertise, engineering and manufacturing excellence in order to meet the exact specifications and quality standards required for their drug products. In 2021, we significantly ramped up our efforts to align Stevanato’s corporate culture with relevant environmental, social and governance elements. We are committed to embedding sustainability values into policies and practices and establishing a culture of integrity. We are also dedicated to satisfying our sta- keholders’ interests and expectations. In this respect, we strive to grow and support our customers while making a positive impact for the benefit of all, in everything we do. We consider ourselves an interdependent and responsible member of the community we live in and, as such, we do our part to promote initiatives and solutions that foster the health and wellbeing of society and the planet. For the first time, we have voluntarily elected to provide complete, transparent non-financial reporting to our stakeholders and investors. Our 2021 Sustainability Report not only considers the Company’s financial and economic results, but also highlights the environmental, social and governance (ESG) performance of the Group. This is our first published Sustainability Report subject to limited assurance and prepared in accordance with the Global Reporting Initiative (GRI) Standards, which demonstrates our unwavering commitment to sustainability. V |

Sustainability Report—2021 In regards to ESG governance, the Board has shown its strong commitment through the constitution of the ESG Committee. Several functions are involved in the management of ESG matters according to each relevant area of accountability. As a baseline, Stevanato Group tackles ESG risks and opportunities in accordance with current legislation and regulations. In the last quarter of 2021, real GDP growth in the euro area slowed down after two quarters of strong expansion but reached its pre-pandemic level at the end of 2021. Hence, GDP is estimated to have increased by 5.2% in 2021 following a 6.4% decline in 2020. The U.S. economy recovered from the recession caused by Covid-19 with GDP returning to pre-pandemic levels as early as mid-2021. Expansionary growth in China, however, remained weak. In the fourth quarter of 2021, China’s GDP growth rose to 1.6% over the previous quarter, an increase that brought twelve-month growth to 8.1% in 2021. The emergence of the Omicron variant continues to pose risks to growth in the short term. Thus, growth is likely to remain subdued in the first quarter of 2022 as the ongoing pandemic continues to affect economic activity. High uncertainty also stems from the conflict between Russia and Ukraine which erupted at the end of February 2022, posing potentially severe economic consequences. Since the outbreak of COVID-19, we have increased production capacity to support our customers’ efforts to provide a rapid response. In this context, we have been providing: (i) glass vials and syringes to approximately 90% of the currently marketed vaccine programs, according to estimates based on public information (WHO, EMA, FDA); and (ii) plastic diagnostic consumables for the detection and diagnosis of COVID19. COVID-19 has generated increased demand for our products and services, further enabling us to accelerate our growth strategy. Going forward, we expect demand for syringes, vials and related products and services to remain elevated as the COVID-19 vaccine and treatment programs continue to roll-out globally, and as our customers contemplate the transition from mul-ti-dose to single-dose formats. In addition, we expect continued tailwinds as epidemic preparedness, including the ongoing global COVID-19 vaccine rollout, booster shot distribution and new vaccination programs, remains a priority for governments. The Company has made meaningful progress and significant milestones were achieved in 2021. None of this would have been possible without the invaluable contribution of our dedicated and passionate employees. We would also like to express our sincere appreciation to Stevanato Group’s stakeholders—our suppliers, customers, universities and research centers—as well as our shareholders and Board of Directors, communities, local authority and regulators. You have been, and will continue to be, an integral part of our success. Much has been done, but even more is left to do. Challenges are part of our history and the stepping stones to the future we intend to build, day after day. Franco Stevanato Executive Chairman Stevanato Group S.p.A. Via Molinella 17, 35017 Piombino Dese · Padova · Italy Franco Moro Chief Executive Officer & Chief Operating Officer Stevanato Group S.p.A. Via Molinella 17, 35017 Piombino Dese · Padova · Italy VI |

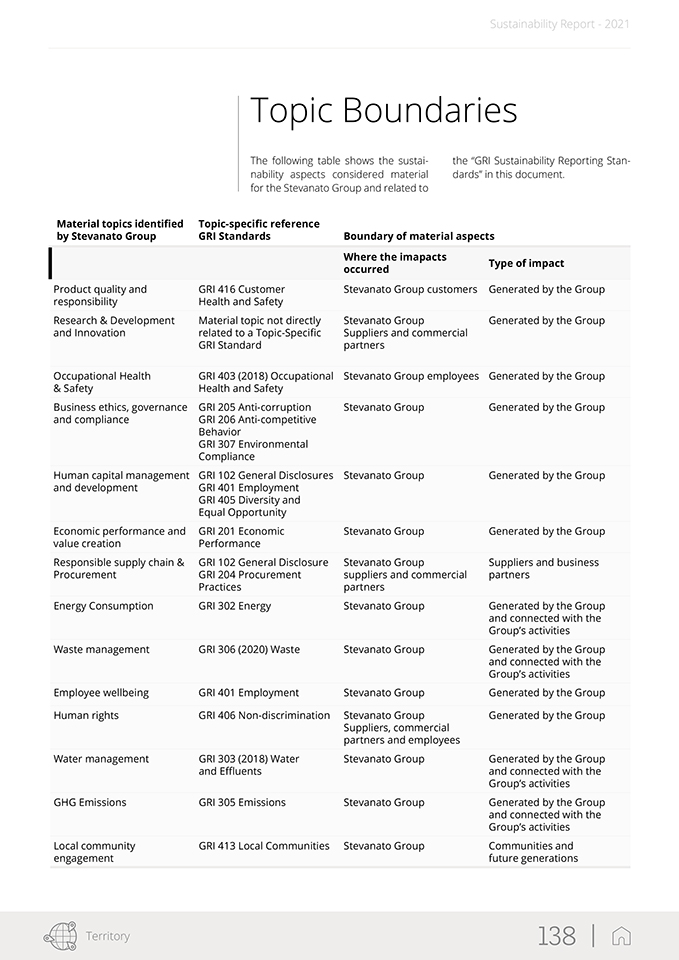

Sustainability Report—2021 Methodological note Our first official and published Sustainability Report is a vehicle for describing, in a transparent and structured manner, Stevanato Group’s environmental, social and economic achievements in the 2021 financial year (January 1-December 31) and shows the commitment and initiatives undertaken towards the goal of sustainable development. Therefore, the purpose of the information contained in this document is to provide internal and external stakeholders with a representation of Stevanato Group’s business performance, results and impact in relation to the main sustainability topics relating to the 2021 financial year. This document represents the Sustainability Report of the companies belonging to Stevanato Group and its subsidiaries (hereinafter also referred to as the “Company”, “Stevanato”, the “Stevanato Group”, the “Group” or “SG”). The scope of the economic data is the same as the 2021 Consolidated Finan- cial Statement of Stevanato Group. The scope of social and environmental data comprises the companies belonging to Stevanato Group as of December 31, 2021, consolidated on a line-by-line basis within the Group Consolidated Financial Statement. Note that some Group companies, which are not productive or operational, have not been included in the EHS aspect due to limitation of scope (see relevant footnotes). This Report, which is going to be published annually, was prepared mainly with reference to the “Global Reporting Initiative (GRI) Sustainability Reporting Standards”. For the specific GRI Standards 303 (Water and water discharges) and GRI 403 (Occupational health and safety), the most recent 2018 versions have been adopted, while for the specific GRI Standard 306 (Waste), the most recent 2020 version has been used. VII |

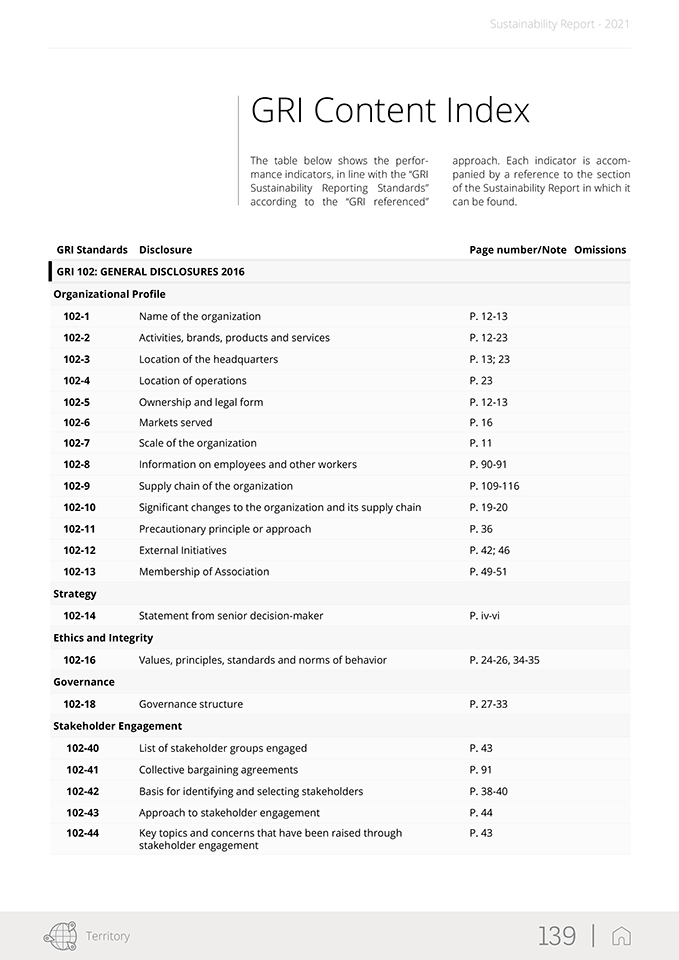

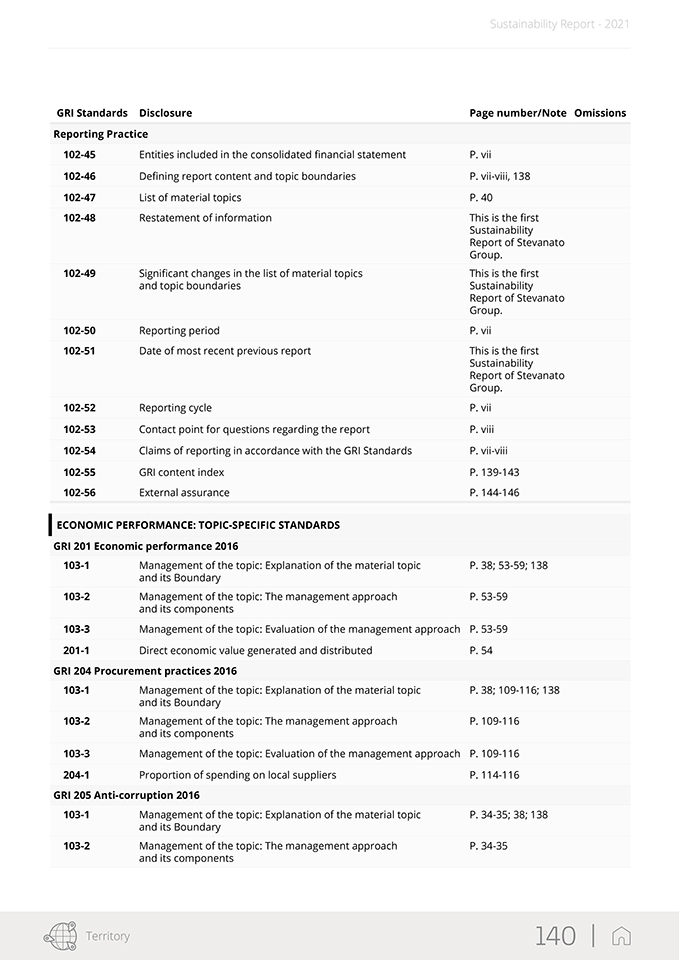

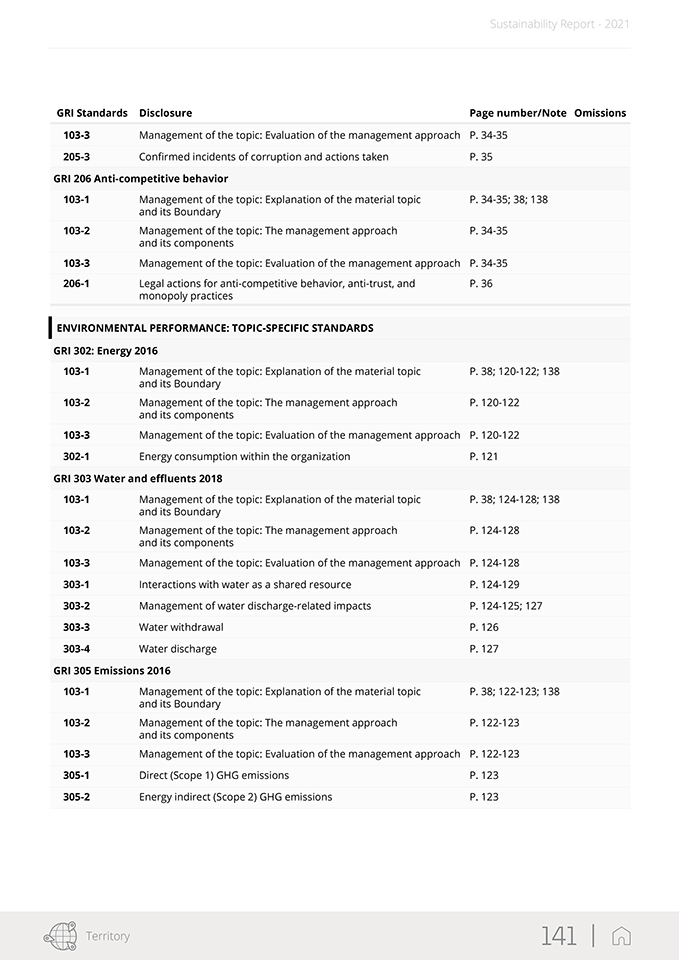

Sustainability Report—2021 The GRI Standards used in this report create a common language between the organization and its internal and external stakeholders so that the environmental, social and economic impacts can be communicated and understood. The following GRI disclosures have been referenced within this document using a “GRI-Referenced” approach: 102-1, 102-2, 102-3, 102-4, 102-5, 102-6, 102-7, 102-8, 102-9, 102-10, 102-11, 102-12, 102-13, 102-14, 102-16, 102-18, 102-40, 102-41, 102-42, 102-43, 102-44, 102-45, 102-46, 102-47, 102-48, 102-49, 102-50, 102-51, 102-52, 102-53, 102-54, 102-55, 102-56, 103- 1, 103-2, 103-3, 201-1, 204-1, 205-3, 206-1, 302-1, 303-1, 303-2, 303-3, 303-4, 305-1, 305-2, 306-1, 306-2, 306-3, 307-1, 401-1, 401-2, 403-1, 403-2, 403-3, 403-4, 403-5, 403-6, 403-7, 403-9, 405-1, 406-1, 413-2, 416-2. For more details, please see the table “GRI Content Index” in the appendix. The contents of the Report were selected based on the results of a materiality analysis carried out in 2020, which identified the material topics for the Group and its stakeholders published within this document as described in Chapter 2. The materiality analysis included the identification of possible ESG (Environmental, Social and Governance) topics relevant to the Group, the prioritization of the topics identified, and their approval by SG’s management. Note that the results of the materiality analysis process were examined and approved by the Board of Director at the meeting held on February 18, 2021. In line with the reporting guidelines, the sustainability information presentation reflects the principle of materiality. In regards to the reporting process, a global working group of approximately one hundred individuals was established from across the Group. The working group was coordinated and supported in its endeavors to determine the most significant information per material topic, select the appropriate indicators, collect and validate the narrative, and define the management approach and pertinent data. Specifically, the information included herein was taken both from the Group’s IT system and from the sustainability reporting package (data collection sheets and narrative collection forms). Plant managers across the Group’s local entities were also asked to identify the most important locally-based projects and initiatives, which were described as required. In order to properly manage the reporting process, a Sustainability Reporting Procedure was set up. It defined and illustrated how to prepare the Group’s Sustainability Report in accordance with the Sustainability Reporting Guidelines issued by the Global Reporting Initiative (GRI). This procedure also included timing, tools, roles and responsibilities of the functions and individuals. To ensure responsiveness and proper application of the procedures, the reporting process was extensively discussed and agreed upon by the working group. The information presented in this report refers solely to 2021 and includes a comparison with the previous year or past where possible. The information collected and reported is based on measurable data. In addition, in order to correctly present the Group’s performance and help to ensure data reliability, the use of estimates has been limited as much as possible. If they are provided, they have been made using the best methods available and are properly identified. The statement presents both positive and negative aspects equally with a comment on the results when appropriate. This report was approved by the Board of Directors of Stevanato Group S.p.A. on April 11, 2022. This document was submitted to a compliance opinion (“limited assurance engagement” according to the criteria indicated by the ISAE 3000 Revised standard) by Deloitte & Touche S.p.A., which expresses, in a separate report, a certificate of compliance with the GRI Standards. The audit was carried out in accordance with the procedures indicated in the “Independent Auditors’ Report”, included in this document. For further information and suggestions regarding Stevanato Group Sustainability Report, please contact: su-stainability@stevanatogroup.com. VIII |

Stevanato Group1

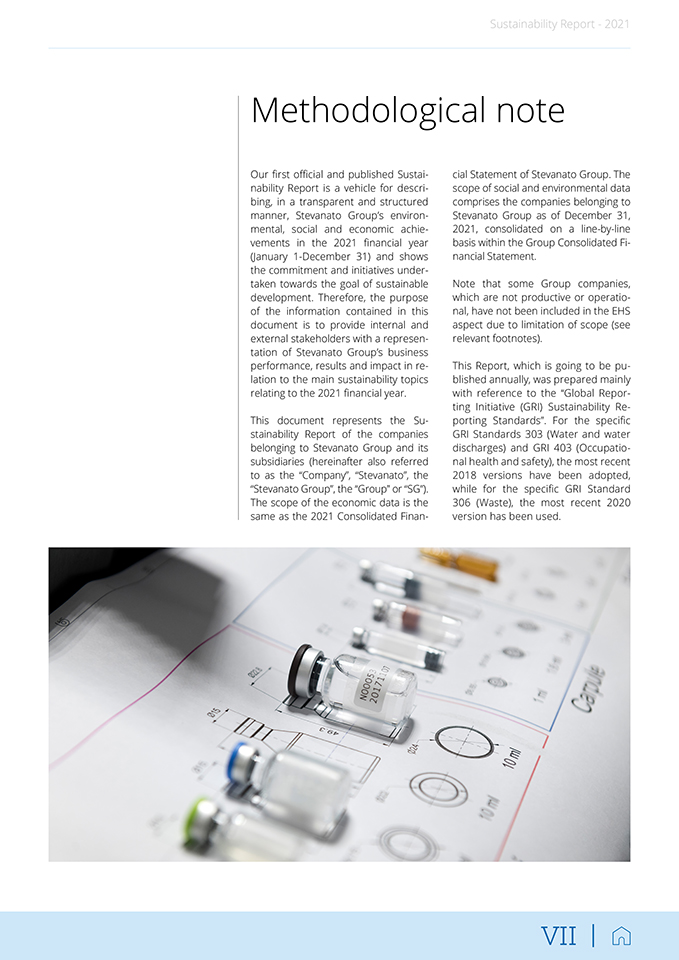

Sustainability Report—2021 1.1 Highlights Stevanato Group 10 |

Sustainability Report—2021 OVER 70YEARS OF HISTORY: FROM A GLASS MANUFACTURER TO A GLOBAL PROVIDER 16 PRODUCTION AND COMMERCIAL SITES IN 9 DIFFERENT COUNTRIES MORE THAN 700CUSTOMERS € 218 MM OF ADJ. EBITDA IN 2021 140 HIGHLY SKILLED PROFESSIONALS #1st IN PEN CARTRIDGES MORE THAN 100 +10% EMPLOYEE INCREASE IN 2021 65% OF RECYCLED WASTE 4,646 EMPLOYEES WORLDWIDE OVER 70 COUNTRIES SERVED € 844 MM OF REVENUE IN 2021 3.5% OF REVENUE INVESTED IN R&D #1st IN SG EZ-fill® PRE-STERILIZED VIALS #2nd IN PRE-FILLABLE SYRINGES THOUSAND HOURS OF TRAINING IN 2021 20% FEMALE DIRECTORS AND MANAGERS 8 DIFFERENT ISO CERTIFICATIONS Stevanato Group 11 |

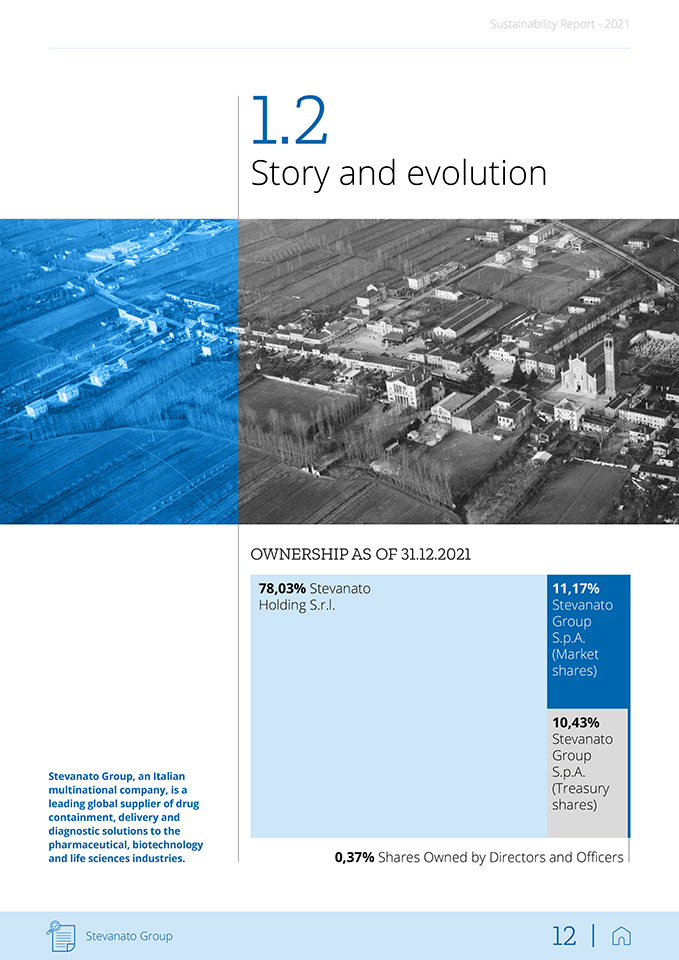

Sustainability Report—2021 1.2 Story and evolution Stevanato Group, an Italian multinational company, is a leading global supplier of drug containment, delivery and diagnostic solutions to the pharmaceutical, biotechnology and life sciences industries. OWNERSHIP AS OF 31.12.2021 78,03% Stevanato 11,17% Holding S.r.l. Stevanato Group S.p.A. (Market shares) 10,43% Stevanato Group S.p.A. (Treasury shares) 0,37% Shares Owned by Directors and Officers Stevanato Group 12 |

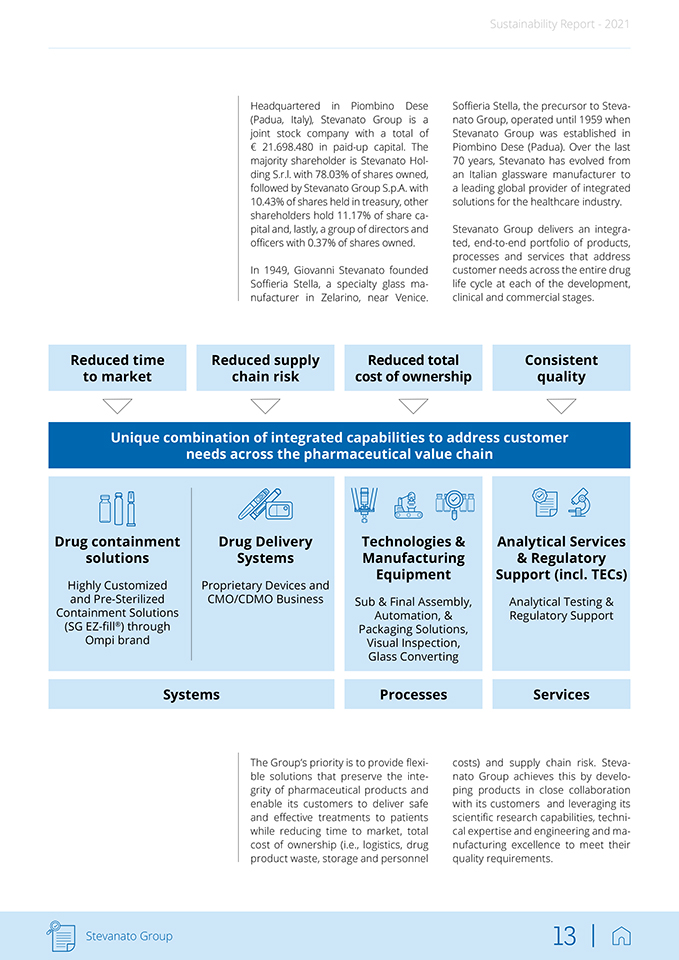

Sustainability Report—2021 Headquartered in Piombino Dese (Padua, Italy), Stevanato Group is a joint stock company with a total of € 21.698.480 in paid-up capital. The majority shareholder is Stevanato Holding S.r.l. with 78.03% of shares owned, followed by Stevanato Group S.p.A. with 10.43% of shares held in treasury, other shareholders hold 11.17% of share capital and, lastly, a group of directors and officers with 0.37% of shares owned. In 1949, Giovanni Stevanato founded Soffieria Stella, a specialty glass manufacturer in Zelarino, near Venice. Soffieria Stella, the precursor to Steva-nato Group, operated until 1959 when Stevanato Group was established in Piombino Dese (Padua). Over the last 70 years, Stevanato has evolved from an Italian glassware manufacturer to a leading global provider of integrated solutions for the healthcare industry. Stevanato Group delivers an integrated, end-to-end portfolio of products, processes and services that address customer needs across the entire drug life cycle at each of the development, clinical and commercial stages. Reduced time Reduced supply Reduced total Consistent to market chain risk cost of ownership quality Unique combination of integrated capabilities to address customer needs across the pharmaceutical value chain Drug containment solutions Highly Customized and Pre-Sterilized Containment Solutions (SG EZ-fill®) through Ompi brand Drug Delivery Systems Proprietary Devices and CMO/CDMO Business Technologies & Manufacturing Equipment Sub & Final Assembly, Automation, & Packaging Solutions, Visual Inspection, Glass Converting Analytical Services & Regulatory Support (incl. TECs) Analytical Testing & Regulatory Support Systems Processes Services The Group’s priority is to provide flexible solutions that preserve the integrity of pharmaceutical products and enable its customers to deliver safe and effective treatments to patients while reducing time to market, total cost of ownership (i.e., logistics, drug product waste, storage and personnel costs) and supply chain risk. Steva-nato Group achieves this by developing products in close collaboration with its customers and leveraging its scientific research capabilities, technical expertise and engineering and manufacturing excellence to meet their quality requirements. Stevanato Group 13 |

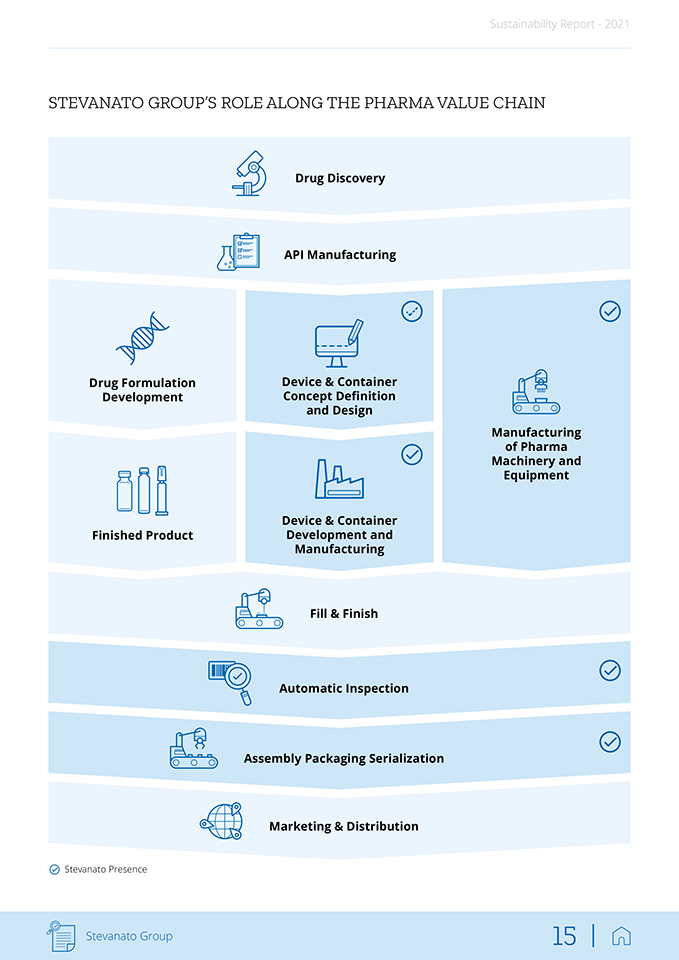

Sustainability Report—2021 Stevanato Group solutions are highly integrated with the development, production and commercialization processes of customers. In addition to manufacturing drug containment and delivery solutions, Stevanato provides a full set of services across all stages of drug development, from pre-clinical to clinical and commercialization. The Group also engineers machinery and equipment for the production of drug containment and delivery systems that can be integrated into both its customers’ and its own manufacturing processes. The Group’s involvement at each stage of a drug’s life cycle, together with the breadth of Stevanato’s offerings, enables it to serve as a one-stop-shop for customers, which gives Stevanato Group a significant competitive advantage. The chart below illustrates the Group’s presence across the pharmaceutical value chain. Stevanato Group operates across the healthcare industry and serves some of its fastest-growing segments, including biologics, biosimilars, vaccines and molecular diagnostics. The Group is embedded in the drug production and delivery supply chain and well-positioned to benefit from secular trends within its targeted focus areas, such as increases in demand resulting from pharmaceutical innovation, acceleration and expansion of vaccination programs, growth of biologics/biosimilars, self-administration of medicines, aging demographics, increasing complexities in health conditions and co-morbidities, and evolving quality standards and regulation. Stevanato Group 14 |

Sustainability Report—2021 STEVANATO GROUP’S ROLE ALONG THE PHARMA VALUE CHAIN Drug Discovery API Manufacturing Drug Formulation Development Device & Container Concept Definition and Design Manufacturing of Pharma Machinery and Equipment Finished Product Device & Container Development and Manufacturing Fill & Finish Automatic Inspection Assembly Packaging Serialization Marketing & Distribution Stevanato Presence Stevanato Group 15 |

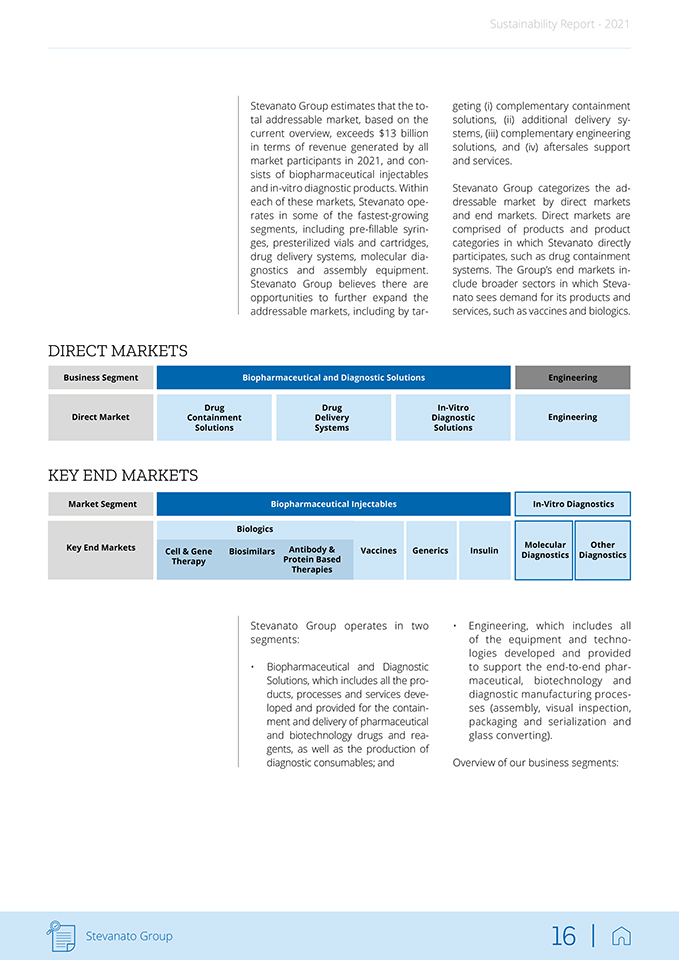

Sustainability Report—2021 Stevanato Group estimates that the to¬tal addressable market, based on the current overview, exceeds $13 billion in terms of revenue generated by all market participants in 2021, and con¬sists of biopharmaceutical injectables and in-vitro diagnostic products. Within each of these markets, Stevanato ope¬rates in some of the fastest-growing segments, including pre-filiable syrin¬ges, presterilized vials and cartridges, drug delivery systems, molecular dia¬gnostics and assembly equipment. Stevanato Group believes there are opportunities to further expand the addressable markets, including by tar¬geting (i) complementary containment solutions, (ii) additional delivery sy¬stems, (iii) complementary engineering solutions, and (iv) aftersales support and services. Stevanato Group categorizes the ad-dressable market by direct markets and end markets. Direct markets are comprised of products and product categories in which Stevanato directly participates, such as drug containment systems. The Group’s end markets in-clude broader sectors in which Steva¬nato sees demand for its products and services, such as vaccines and biologies. DIRECT MARKETS Business Segment Engineering Drug Drug In-Vitro Direct Market ContainmentDeliveryDiagnostic Engineering SolutionsSystemsSolutions KEY END MARKETS Market Segment Biopharmaceutical Injectables In-Vitro Diagnostics Molecular Other Diagnostics Diagnostics Stevanato Group operates in two segments: Biopharmaceutical and Diagnostic Solutions, which includes all the pro-ducts, processes and services deve-loped and provided for the contain-ment and delivery of pharmaceutica and biotechnology drugs and rea-gents, as well as the production of diagnostic consumables; and • Engineering, which includes all of the equipment and techno¬logies developed and provided to support the end-to-end phar¬maceutical, biotechnology and diagnostic manufacturing proces¬ses (assembly, visual inspection, packaging and serialization and glass converting). Overview of our business segments: it ED Stevanato Group 16 |

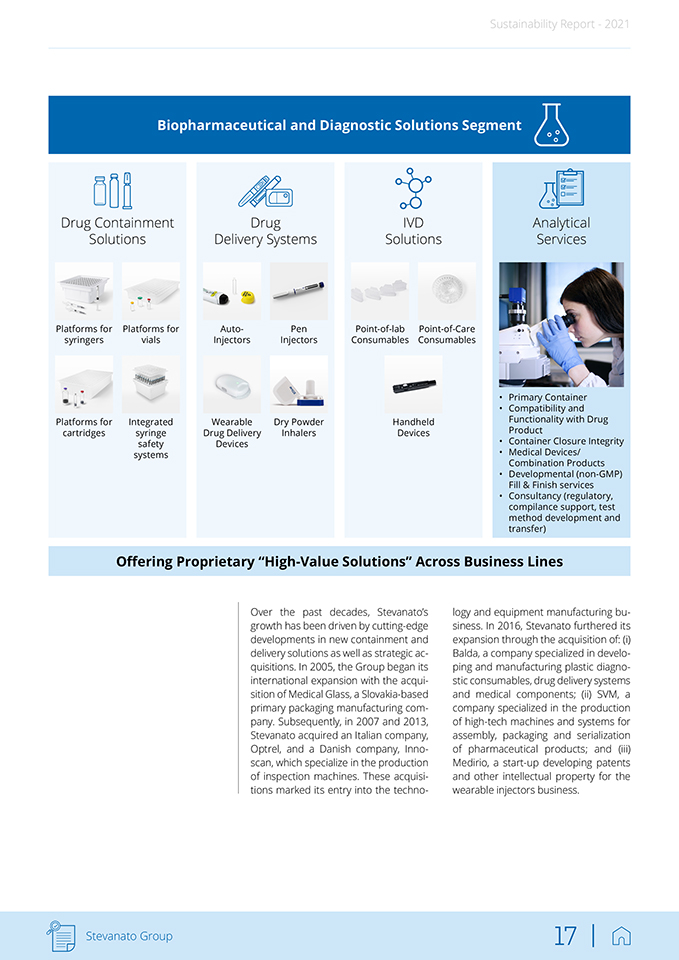

Sustainability Report—2021 Biopharmaceutical and Diagnostic Solutions Segment Drug Containment Solutions Platforms for Platforms for syringers vials Platforms for Integrated cartridges syringe safety systems Drug Delivery Systems Auto- Pen Injectors Injectors Wearable Dry Powder Drug Delivery Inhalers Devices IVD Solutions Point-of-lab Point-of-Care Consumables Consumables Handheld Devices Analytical Services • Primary Container • Compatibility and Functionality with Drug Product • Container Closure Integrity • Medical Devices/ Combination Products • Developmental (non-GMP) Fill & Finish services • Consultancy (regulatory, compilance support, test method development and transfer) Offering Proprietary “High-Value Solutions” Across Business Lines Over the past decades, Stevanato’s growth has been driven by cutting-edge developments in new containment and delivery solutions as well as strategic acquisitions. In 2005, the Group began its international expansion with the acquisition of Medical Glass, a Slovakia-based primary packaging manufacturing company. Subsequently, in 2007 and 2013, Stevanato acquired an Italian company, Optrel, and a Danish company, Inno-scan, which specialize in the production of inspection machines. These acquisitions marked its entry into the techno- logy and equipment manufacturing business. In 2016, Stevanato furthered its expansion through the acquisition of: (i) Balda, a company specialized in developing and manufacturing plastic diagnostic consumables, drug delivery systems and medical components; (ii) SVM, a company specialized in the production of high-tech machines and systems for assembly, packaging and serialization of pharmaceutical products; and (iii) Medirio, a start-up developing patents and other intellectual property for the wearable injectors business. Stevanato Group 17 |

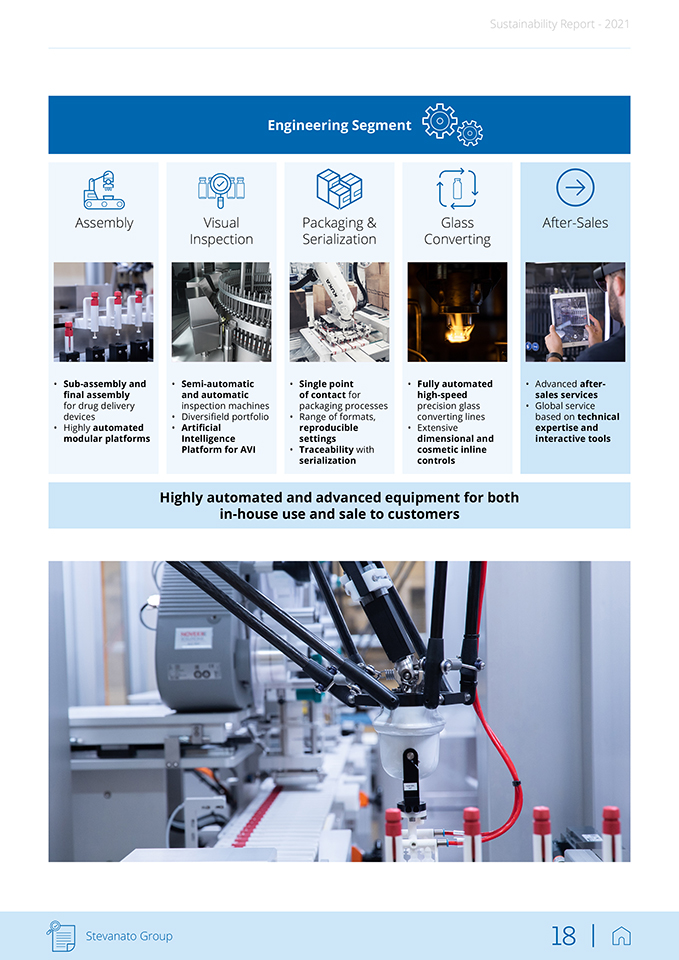

Sustainability Report—2021 Engineering Segment Assembly • Sub-assembly and final assembly for drug delivery devices • Highly automated modular platforms Visual Inspection • Semi-automatic and automatic inspection machines • Diversifield portfolio • Artificial Intelligence Platform for AVI Packaging & Serialization • Single point of contact for packaging processes • Range of formats, reproducible settings • Traceability with serialization Glass Converting • Fully automated high-speed precision glass converting lines • Extensive dimensional and cosmetic inline controls After-Sales • Advanced after-sales services • Global service based on technical expertise and interactive tools Highly automated and advanced equipment for both in-house use and sale to customers Stevanato Group 18 |

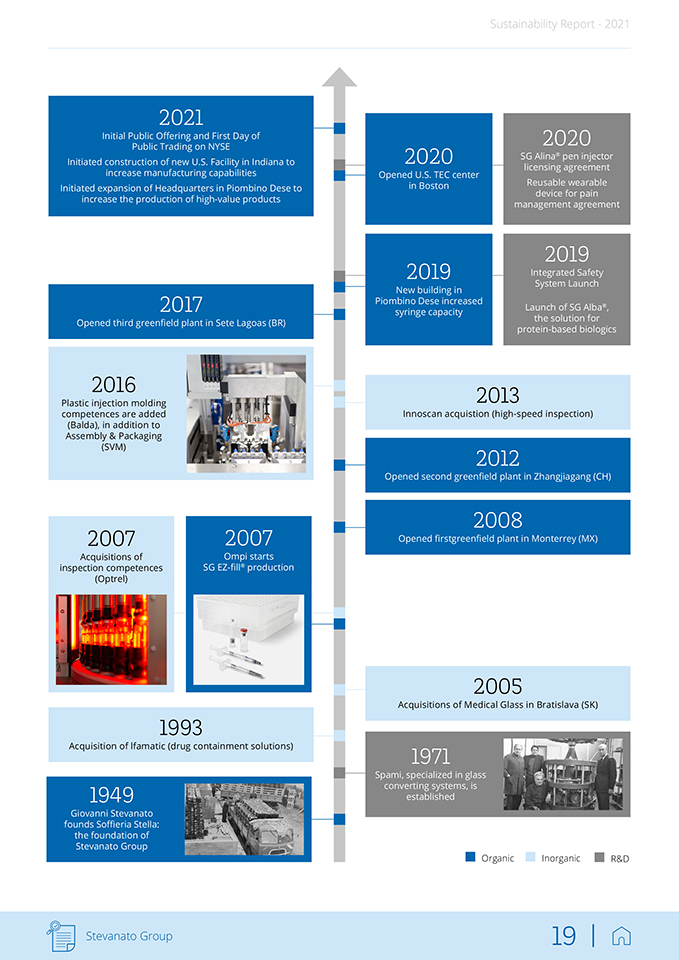

Sustainability Report—2021 2021 Initial Public Offering and First Day of Public Trading on NYSE Initiated construction of new U.S. Facility in Indiana to increase manufacturing capabilities Initiated expansion of Headquarters in Piombino Dese to increase the production of high-value products 2017 Opened third greenfield plant in Sete Lagoas (BR) 2016 Plastic injection molding competences are added (Balda), in addition to Assembly & Packaging (SVM) 2007 Acquisitions of inspection competences (Optrel) 2007 Ompi starts SG EZ-fill® production 1993 Acquisition of lfamatic (drug containment solutions) 1949 Giovanni Stevanato founds Soffieria Stella: the foundation of Stevanato Group 2020 Opened U.S. TEC center in Boston 2019 New building in Piombino Dese increased syringe capacity 2020 SG Alina® pen injector licensing agreement Reusable wearable device for pain management agreement 2019 Integrated Safety System Launch Launch of SG Alba®, the solution for protein-based biologics 2013 Innoscan acquistion (high-speed inspection) 2012 Opened second greenfield plant in Zhangjiagang (CH) 2008 Opened firstgreenfield plant in Monterrey (MX) 2005 Acquisitions of Medical Glass in Bratislava (SK) 1971 Spami, specialized in glass converting systems, is established Organic Inorganic R&D Stevanato Group 19 |

Sustainability Report—2021 In parallel with Stevanato’s acquisition strategy, the Group regularly reviews its operations in the context of its organic growth plan. As a result of these ongoing assessments, Stevanato Group has expanded its offering through new departments, new laboratories, new offices and new plants. In 2019, Stevana-to opened a new building in Piombino Dese (Italy) to increase its syringe production capacity, and since 2008, the Group has opened three greenfield sites in (i) Monterrey, Mexico in 2008; (ii) Zhangjiagang, China in 2012; and (iii) Sete Lagoas, Brazil in 2017. In 2021, the Group announced plans to expand its global market position in high-value solutions by investing in additional capacity in the U.S. and China to meet the growing demands of the expanding pharmaceutical, biotech-nology and vaccine markets. The site in Fishers, Indiana, USA, will enable the Group to better serve its North America pharmaceutical customers with the production of pre-sterilized EZ-fill® syringes and vials. The capacity expansion for EZ-fill® products in Zhangjiagang, China, also has a strong focus on biologics and vaccines in addition to focusing on solutions for the engineering segment. Another capacity expansion is planned in Italy where it will generate new jobs. The Group will follow best practices to improve both environmental and societal impacts using the latest in technology and sustainable solutions. Finally, in 2021 Stevanato Group finalized the consolidation of its plastic component operations in the Balda, Ontario site. The expansion of the On-tario plant was carefully implemented, minimizing impact on the staff and customers’ production schedules, and will greatly improve its level of service, reduce time to market, and simplify supply chain and customer interfaces. This rich history of organic growth and strategic acquisitions has allowed Ste-vanato Group to create a comprehensive portfolio of integrated products, capabilities, technologies and services for the pharmaceutical and heal-thcare industries. The main company brands are: • Ompi – Drug Containment Solutions: with more than 70 years of experience, Ompi is specialized in the production of glass primary packaging for pharmaceutical use and collaborates with pharma companies to continually raise its quality standards and develop customized solutions. • Balda – IVD and Drug Delivery Systems Solutions: founded in 1908, Balda specializes in high-precision plastic injection molding for pharmaceutical and healthcare applications including diagnostic consumables, dispensing devices and medical components. Balda offers both contract manufacturing and development services. • Lab/TEC – Analytical Services: born in 2015, SG Lab Analytics holds a leading edge in scientific and technological expertise. It offers a wide range of analytical services related to glass primary packaging with a focus on analytical chemistry, material properties, and physical and mechanical performance. Inaugurated in Boston, USA, in 2020 the Technology Excellence Center (TEC) provides biopharma companies with integrated analytical services and effective project management to support their drug development activities from early phase to commercialization and lifecycle management. • Spami – Glass Converting Equipment: Since 1971, Spami has been the technological leader in designing and assembling automated lines for the transformation of glass tubing into containers for pharmaceutical use. It continuously upgrades its technologies, addressing the real needs of glass tubing packaging manufacturers, offering higher quality, stability, output speed and facility of use. Stevanato Group 20 |

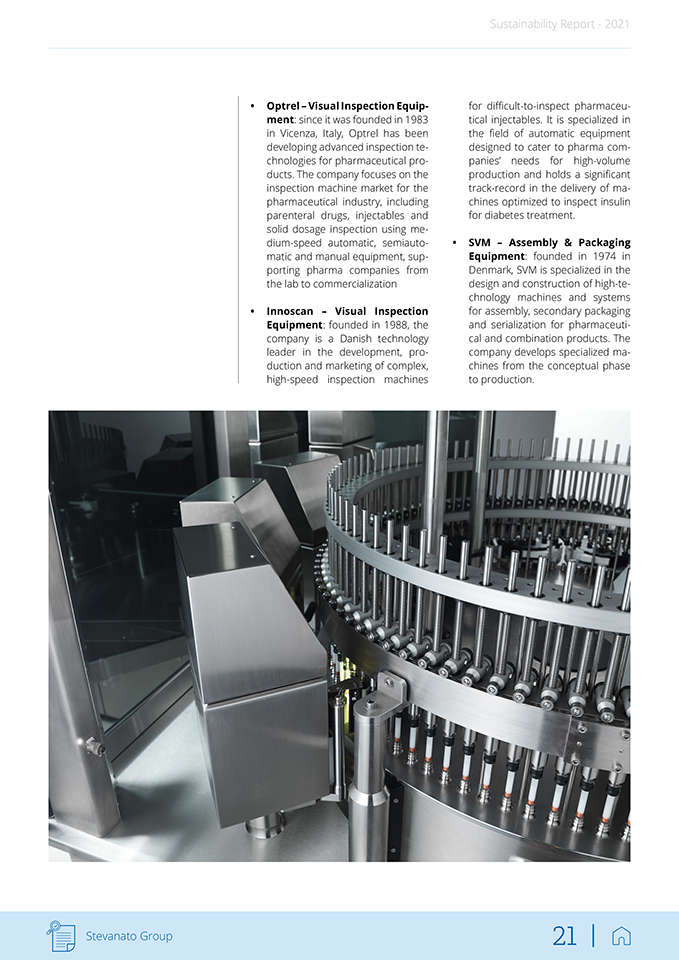

Sustainability Report—2021 • Optrel – Visual Inspection Equipment: since it was founded in 1983 in Vicenza, Italy, Optrel has been developing advanced inspection technologies for pharmaceutical products. The company focuses on the inspection machine market for the pharmaceutical industry, including parenteral drugs, injectables and solid dosage inspection using medium-speed automatic, semiauto-matic and manual equipment, supporting pharma companies from the lab to commercialization • Innoscan – Visual Inspection Equipment: founded in 1988, the company is a Danish technology leader in the development, production and marketing of complex, high-speed inspection machines for difficult-to-inspect pharmaceutical injectables. It is specialized in the field of automatic equipment designed to cater to pharma companies’ needs for high-volume production and holds a significant track-record in the delivery of machines optimized to inspect insulin for diabetes treatment. SVM – Assembly & Packaging Equipment: founded in 1974 in Denmark, SVM is specialized in the design and construction of high-technology machines and systems for assembly, secondary packaging and serialization for pharmaceutical and combination products. The company develops specialized machines from the conceptual phase to production. Stevanato Group 21 |

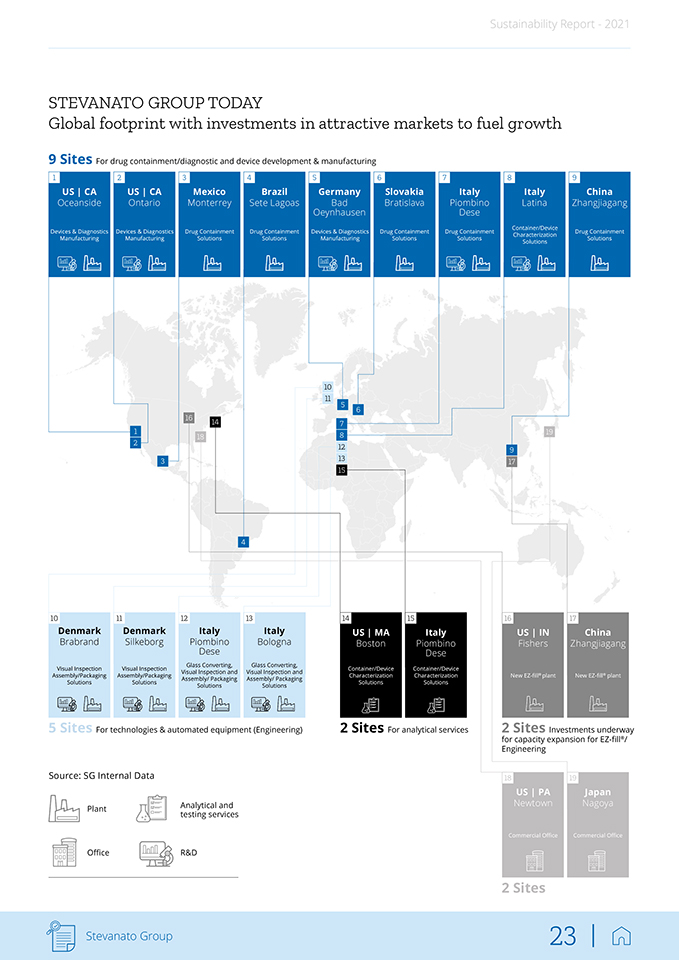

Sustainability Report—2021 The combination of multinational a truly global company spread across dif-brands has transformed the Group into ferent countries and continents: 9 production plants for manufacturing and assembly of pharmaceutical and healthcare products across the world: • Drug containment solutions: • Italy – Piombino Dese (PD), Latina (LT); • Slovakia – Bratislava; • Mexico – Monterrey; • Brazil – Sete Lagoas; • China – Zhangjjagang; • IVD and Drug Delivery Systems Solutions: • Germany – Bad Oeynhausen; • USA – Ontario (CA), Oceanside (CA)1. 5 plants for the engineering and production of technologies and manufacturing equipment: • Glass Converting: • Italy – Piombino Dese (PD), Bologna; • Visual Inspection: • Italy – Piombino Dese (PD); • Denmark – Brabrand; • Assembly & Packaging: • Italy – Piombino Dese (PD), Bologna; • Denmark – Silkeborg. 2 sites for analytical services: • Italy – Piombino Dese (PD); • USA – Boston (MA). 2 commercial offices: • Japan – Nagoya; • USA – Newton (PA). 2 sites under construction: • USA – Fishers (IN); • China – Zhangjjagang. The manufacturing facilities in Mexico, China, Brazil and the hub under construction in the US all represent gre-enfield operations built by the Group. Facilities in Slovakia, Germany, Den-mark and the United States (the plant dedicated to IVD and DDS Solutions) were acquired in strategic transactions over the past 15 years. Our global presence, together with proprietary, standardized manufacturing systems and processes, allow the Group to provide consistent product and services standards to its customers in approximately 70 countries around the world. 1. Balda Precision Inc., Production metal components. Stevanato Group 22 |

Sustainability Report—2021 STEVANATO GROUP TODAY Global footprint with investments in attractive markets to fuel growth 9 Sites For drug containment/diagnostic and device development & manufacturing 1 2 3 4 5 6 7 8 9 US | CA US | CA Mexico Brazil Germany Slovakia Italy Italy China Oceanside Ontario Monterrey Sete Lagoas Oeynhausen Bad Bratislava Piombino Dese Latina Zhangjiagang Container/Device Devices & Diagnostics Devices & Diagnostics Drug Containment Drug Containment Devices & Diagnostics Drug Containment Drug Containment Drug Containment Characterization Manufacturing Manufacturing Solutions Solutions Manufacturing Solutions Solutions Solutions Solutions 10 11 5 6 16 14 7 1 19 18 8 2 12 9 3 13 17 15 4 10 11 12 13 14 15 16 17 Denmark Denmark Italy Italy US | MA Italy US | IN China Brabrand Silkeborg Piombino Dese Bologna Boston Piombino Fishers Zhangjiagang Dese Glass Converting, Glass Converting, Visual Inspection Visual Inspection Container/Device Container/Device Visual lnspection and Visual lnspection and ® ® Assembly/Packaging Assembly/Packaging Characterization Characterization New EZ-fill plant New EZ-fill plant Assembly/ Packaging Assembly/ Packaging Solutions Solutions Solutions Solutions Solutions Solutions 5 Sites For technologies & automated equipment (Engineering) 2 Sites For analytical services 2 Sites Investments underway for capacity expansion for EZ-fill®/ Engineering Source: SG Internal Data 18 19 US | PA Japan Analytical and Newtown Nagoya Plant testing services Commercial Office Commercial Office Office R&D 2 Sites Stevanato Group 23 |

Sustainability Report—2021 1.3 Mission, Vision and Values Stevanato Group’s Vision, Mission and Values provide a framework to guide the company’s pursuit of business goals with an ethical and transparent mindset and focus on fostering innovation. Stevanato Group 24 |

Sustainability Report—2021 MISSION The Group is committed to creating systems, processes and services that enhance the integrity of medicines. It strives to be the best, objective-focused partner in the research and delivery of innovative solutions to support the success of its customers. The continual innovation and pioneering of new trends in pharmaceutical glass packaging ensures the production of the world’s most advanced solutions year after year, enhancing the level of product integrity guaranteed to patients and always seeking to exceed customer expectations. Geographical Product Focus on customer Operational Quality portfolio and patient excellence Merges and Social Innovation Financial Research and acquisition development VISION & VALUES At the heart of Stevanato Group’s vision is the desire to drive technological innovations that combine pharmaceutical glass products and processes into systems, which then enhance the integrity of parenteral drugs in a way that is far superior to anything that has been achieved before. Stevanato Group’s vision is based on five fundamental values, each one closely connected to the other in order to guarantee synergistic collaboration and leadership rooted in excellence. Employees within the Group are particularly dedicated to being ethical and accountable in their day-to-day actions and are driven to deliver results. Listen and Trust and respect Be Deliver Be ethical communicate with everyone accountable results always transparency and honesty Stevanato Group 25 |

Sustainability Report—2021 GUIDING PRINCIPLES Guiding Principles provide practical direction on how to be more effective in living the company Values every day. They help Stevanato Group’s people to work as an aligned, integrated team in pursuit of the mutual goal of building value for the Group, with a focus on customer needs, best product development, and efficiency. Being humble, competent and ready to aim for excellence are the principles that have characterized Stevanato Group, helping it to become the corporation it is today. The adoption of the Guiding Principles leads the Group towards achieving its Mission and creates systems, processes and services that guarantee the integrity of medicines. Will to win Competence, Consistency well, have a Don’t be Humility experience and execution and big goal standard preparation decision making Stevanato Group 26 |

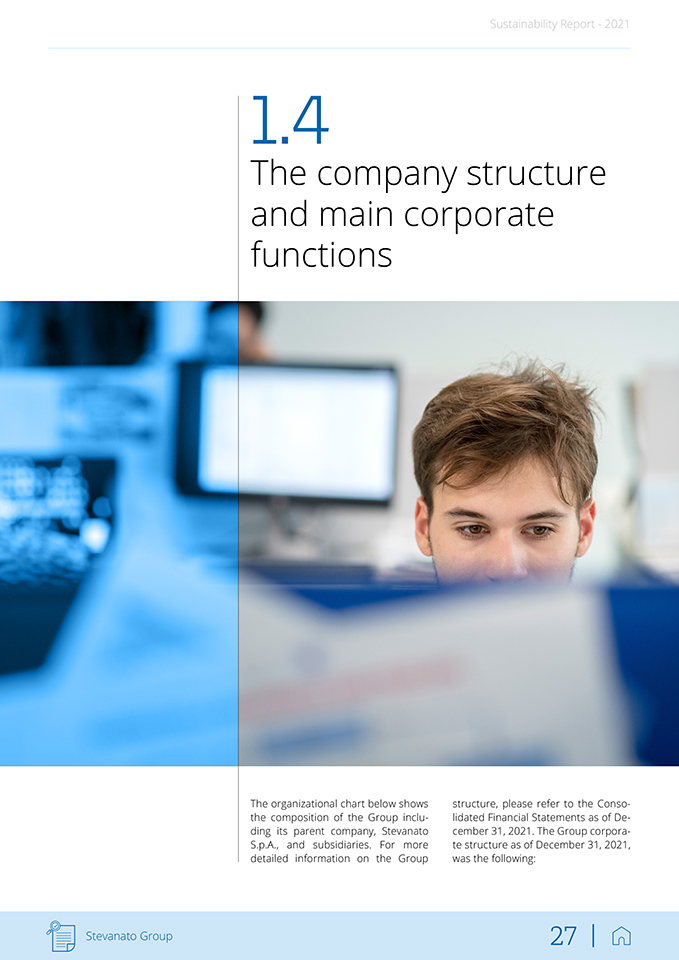

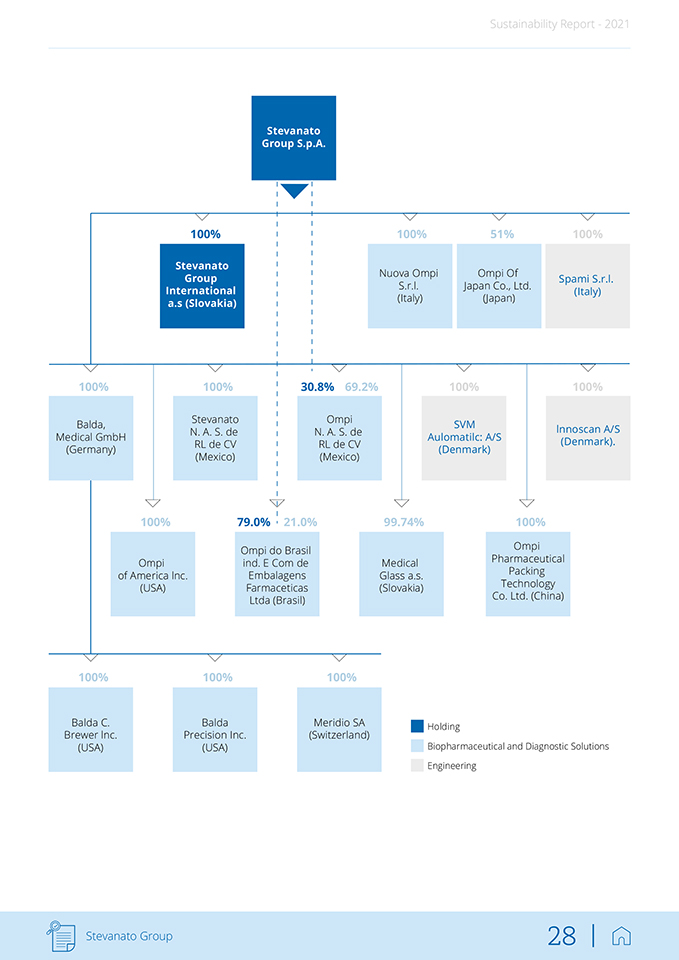

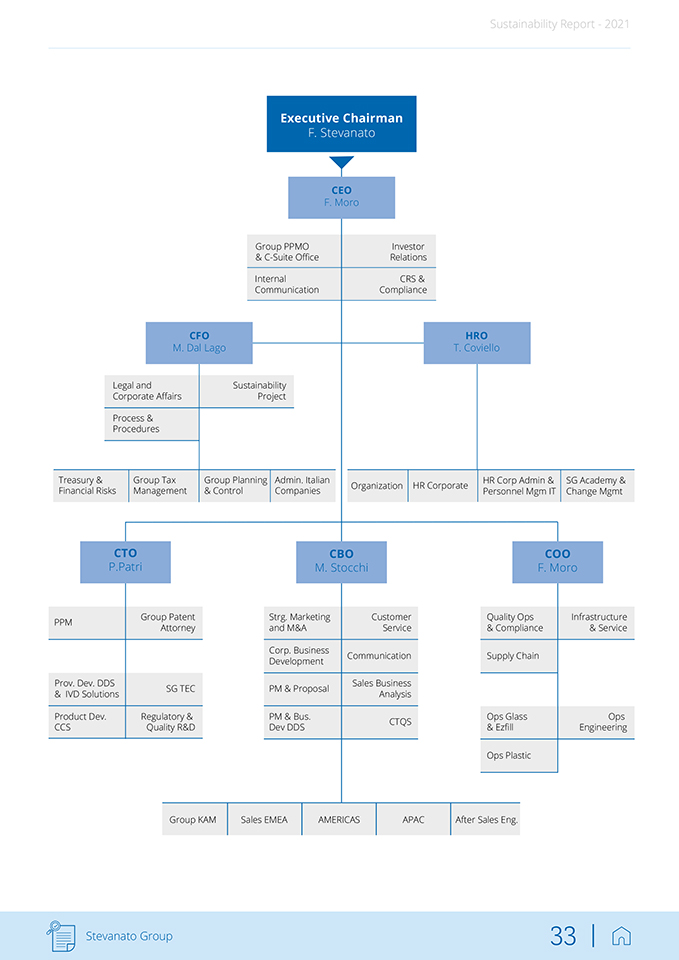

Sustainability Report—2021 1.4 The company structure and main corporate functions The organizational chart below shows the composition of the Group including its parent company, Stevanato S.p.A., and subsidiaries. For more detailed information on the Group structure, please refer to the Consolidated Financial Statements as of De-cember 31, 2021. The Group corporate structure as of December 31, 2021, was the following: Stevanato Group 27 |

Sustainability Report—2021 Stevanato Group S.p.A. 100% 100% 51% 100% Stevanato Group Nuova Ompi Ompi Of Spami S.r.l. International S.r.l. Japan Co., Ltd. (Italy) a.s (Slovakia) (Italy) (Japan) 100% 100% 30.8% 69.2% 100% 100% Balda, Stevanato Ompi SVM N. A. S. de N. A. S. de lnnoscan A/S Medical GmbH Aulomatilc: A/S (Denmark). (Germany) RL de CV RL de CV (Denmark) (Mexico) (Mexico) 100% 79.0% 21.0% 99.74% 100% Ompi do Brasil Ompi Ompi ind. E Com de Medical Pharmaceutical of America lnc. Embalagens Glass a.s. Packing (USA) Farmaceticas (Slovakia) Technology Ltda (Brasil) Co. Ltd. (China) 100% 100% 100% Balda C. Balda Meridio SA Holding Brewer lnc. Precision Inc. (Switzerland) (USA) (USA) Biopharmaceutical and Diagnostic Solutions Engineering Stevanato Group 28 |

Sustainability Report—2021 In terms of significant changes to the organizational structure, as of February 22, 2021, Franco Moro has replaced Franco Stevanato as Chief Executive Officer of Stevanato Group, and is responsible for overseeing the execution of business development plans to grow and enhance the company’s end-to-end offering for pharmaceutical and diagnostics companies. Franco Moro previously held key Officer positions within Stevanato Group and has significant experience in international manufacturing and pharmaceutical industries. After this re-organization, Franco Steva-nato is the new Executive Chairman of the Board of Directors, overseeing long-term business strategy, acquisitions, expansion into global markets, and relations with the Board of Directors. Marco Stevanato remains the Vice-Chairman and Sergio Stevanato has been appointed Chairman of the Board Emeritus. Stevanato Group is proud of its heritage. The family’s close ties to the business have been fundamental in allowing the company to expand. It has been able to develop naturally while always understanding the ever-increasing complexity of doing business. As the Group has grown, a structured and skilled management team with international roots has been put into place. Stevanato Group has adopted a corporate governance that sets the rules for the appropriate management of the Group, separating ownership from the operating activities. The Group is managed by the Board of Directors, which meets at least four times per year to make key decisions on reserved topics. The Group is led by an experienced, highly motivated, diverse Board, leading to more objectivity and independence, and an executive team with a proven track record of operational excellence. The Group believes that this has significantly benefitted its strategy building and execution capability, helping it to consistently achieve results by anticipating market trends and staying ahead of the competition. Stevanato Group intends to continue with this approach. As of December 31, 2021, the Board of Directors was composed as follows: Board of Directors at 12.31.2021 Role Stevanato Sergio Chairman of the Board Emeritus Stevanato Franco Executive Chairman Stevanato Marco Vice-Chairman Moro Franco Chief Executive Officer Nicoletti Fabiano Independent Director Spinazzi Alvise Director Bonanni Fabrizio Independent Director Buttignon Fabio Independent Director Balachandran Madhavan Independent Director Morel Jr. Donald Eugene Independent Director Paola Vezzaro Independent Director William Federici Independent Director Stevanato Group 29 |

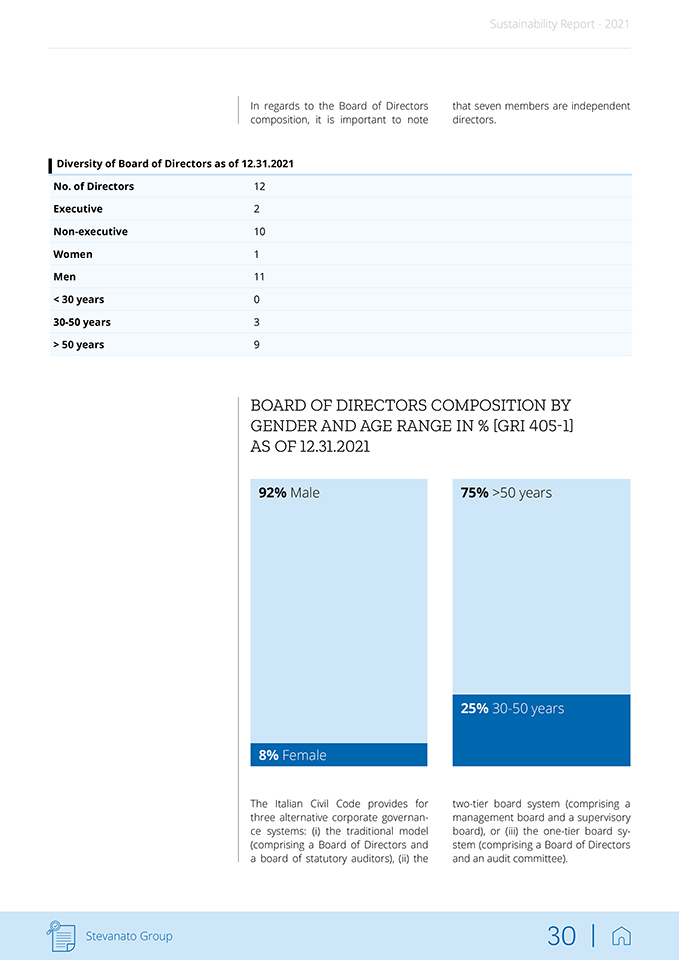

Sustainability Report—2021 In regards to the Board of Directors composition, it is important to note that seven members are independent directors. Diversity of Board of Directors as of 12.31.2021 No. of Directors 12 Executive 2 Non-executive 10 Women 1 Men 11 < 30 years 0 30-50 years 3 > 50 years 9 BOARD OF DIRECTORS COMPOSITION BY GENDER AND AGE RANGE IN % [GRI 405-1] AS OF 12.31.2021 92% Male 8% Female 75% >50 years 25% 30-50 years The Italian Civil Code provides for three alternative corporate governance systems: (i) the traditional model (comprising a Board of Directors and a board of statutory auditors), (ii) the two-tier board system (comprising a management board and a supervisory board), or (iii) the one-tier board system (comprising a Board of Directors and an audit committee). Stevanato Group 30 |

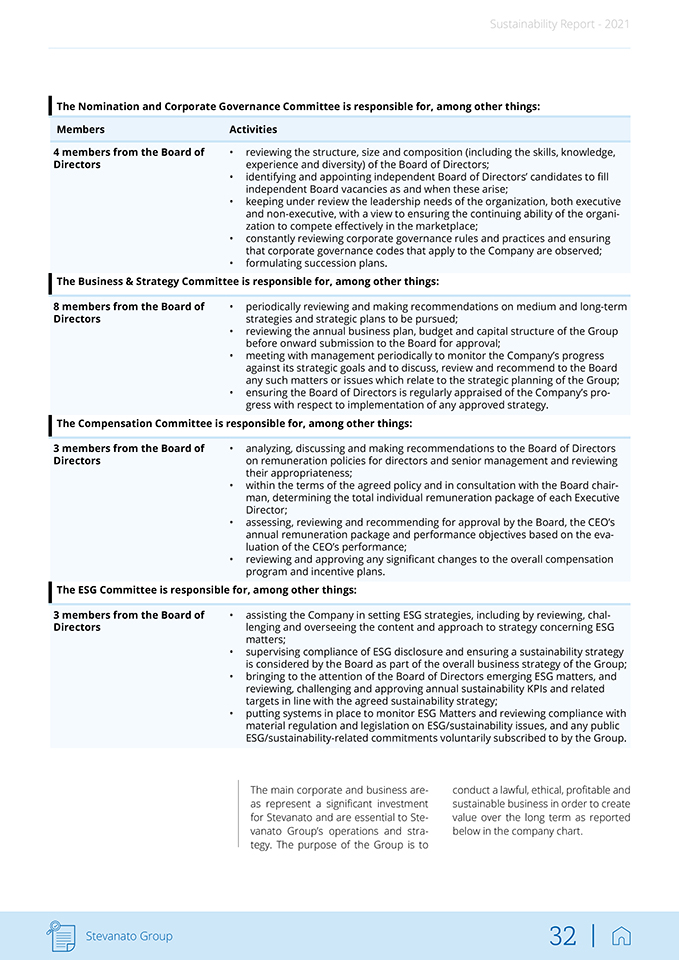

Sustainability Report—2021 In May 2021, Stevanato Group S.p.A. adopted the one-tier corporate governance system which provides for a Board of Directors and an Audit Committee. The Audit Committee consists of Wil-liam Federici, Fabio Buttignon and Fa-brizio Bonanni. Mr. Federici serves as the chairman of the Audit Committee. The Board of Directors determined that all members of the Audit Committee must meet the requirements for financial literacy under the applicable rules and regulations of the SEC and the NYSE corporate governance rules. The Audit Committee is compliant with applicable rules and regulations of the SEC and NYSE corporate governance rules as well as Italian Law requirements with respect to its composition, expertise requisites, functioning and independence. The Audit Committee is responsible for, among other things, assisting the board in the oversight of: • the accounting and financial reporting practices of the Company as well as the integrity of the financial statements; • the adequacy of the Company’s organizational structure, internal control system, and administrative and accounting systems; • the Company’s risk assessment and risk management processes to ensure such processes are effective; • the supervision of compliance with legal and regulatory requirements including, as required by the rules and regulations of the SEC, the preparation of the Audit Committee report to be included in the Company’s annual proxy statement; • the independence and qualifications of the Company’s registered public accounting firm. The Audit Committee meets in a manner that the Audit Committee may deem fit at least once every ninety calendar days. Periodically, the Audit Committee also meets with the independent auditor and members of management. A more detailed analysis of the governance structure indicates there are also four committees that cooperate with the Board of Directors on day-to-day matters. The members of the different committees described in this document share the same term of office with the Board of Directors and provide opinions and suggestions, without prejudice to the Board’s competence and decision-making responsibility. Below is the main composition and activities of the four Stevanato Group committees. Stevanato Group 31 |

Sustainability Report—2021 The Nomination and Corporate Governance Committee is responsible for, among other things: Members Activities 4 members from the Board of • reviewing the structure, size and composition (including the skills, knowledge, Directors experience and diversity) of the Board of Directors; • identifying and appointing independent Board of Directors’ candidates to fill independent Board vacancies as and when these arise; • keeping under review the leadership needs of the organization, both executive and non-executive, with a view to ensuring the continuing ability of the organization to compete effectively in the marketplace; • constantly reviewing corporate governance rules and practices and ensuring that corporate governance codes that apply to the Company are observed; • formulating succession plans. The Business & Strategy Committee is responsible for, among other things: 8 members from the Board of • periodically reviewing and making recommendations on medium and long-term Directors strategies and strategic plans to be pursued; • reviewing the annual business plan, budget and capital structure of the Group before onward submission to the Board for approval; • meeting with management periodically to monitor the Company’s progress against its strategic goals and to discuss, review and recommend to the Board any such matters or issues which relate to the strategic planning of the Group; • ensuring the Board of Directors is regularly appraised of the Company’s progress with respect to implementation of any approved strategy. The Compensation Committee is responsible for, among other things: 3 members from the Board of • analyzing, discussing and making recommendations to the Board of Directors Directors on remuneration policies for directors and senior management and reviewing their appropriateness; • within the terms of the agreed policy and in consultation with the Board chairman, determining the total individual remuneration package of each Executive Director; • assessing, reviewing and recommending for approval by the Board, the CEO’s annual remuneration package and performance objectives based on the evaluation of the CEO’s performance; • reviewing and approving any significant changes to the overall compensation program and incentive plans. The ESG Committee is responsible for, among other things: 3 members from the Board of • assisting the Company in setting ESG strategies, including by reviewing, chal-Directors lenging and overseeing the content and approach to strategy concerning ESG matters; • supervising compliance of ESG disclosure and ensuring a sustainability strategy is considered by the Board as part of the overall business strategy of the Group; • bringing to the attention of the Board of Directors emerging ESG matters, and reviewing, challenging and approving annual sustainability KPIs and related targets in line with the agreed sustainability strategy; • putting systems in place to monitor ESG Matters and reviewing compliance with material regulation and legislation on ESG/sustainability issues, and any public ESG/sustainability-related commitments voluntarily subscribed to by the Group. The main corporate and business areas represent a significant investment for Stevanato and are essential to Ste-vanato Group’s operations and strategy. The purpose of the Group is to conduct a lawful, ethical, profitable and sustainable business in order to create value over the long term as reported below in the company chart. Stevanato Group 32 |

Sustainability Report—2021 Executive Chairman F. Stevanato CEO F. Moro Group PPMO Investor & C-Suite Office Relations Internal CRS & Communication Compliance CFO HRO M. Dal Lago T. Coviello Legal and Sustainability Corporate Affairs Project Process & Procedures Treasury & Group Tax Group Planning Admin. Italian HR Corp Admin & SG Academy & Organization HR Corporate Financial Risks Management & Control Companies Personnel Mgm IT Change Mgmt CTO CBO COO P.Patri M. Stocchi F. Moro Group Patent Strg. Marketing Customer Quality Ops Infrastructure PPM Attorney and M&A Service & Compliance & Service Corp. Business Communication Supply Chain Development Prov. Dev. DDS Sales Business SG TEC PM & Proposal & IVD Solutions Analysis Product Dev. Regulatory & PM & Bus. Ops Glass Ops CTQS CCS Quality R&D Dev DDS & Ezfill Engineering Ops Plastic Group KAM Sales EMEA AMERICAS APAC After Sales Eng. Stevanato Group 33 |

Sustainability Report—2021 1.5 Ethics, integrity and compliance An essential factor for success, and an indispensable asset to the Company’s reputation, is the adoption of high ethical conduct standards. The Values and Guiding Principles followed by the Group are the building blocks of its Code of Ethics. The Code of Ethics defines the guidelines and criteria of conduct for all recipients, and aims to ensure compliance with regulations in force to prevent improper acts or behavior and to help protect the legitimate interests of customers, employees, shareholders, business and financial partners, communities and all the different stakeholder groups. The Code of Ethics has been disseminated in all of Steva-nato Group’s companies. Overall, the Code of Ethics has the function of promoting fairness and loyalty in the management of transactions and human relations, within and outside the Group, by those who work on behalf of the Group. The recipients of the Code of Ethics, who are directors, employees, collaborators, suppliers and all those who, in any way, operate on behalf of the Group, are obliged to observe and enforce the provisions contained in it, by adopting the right behavior designed to preserve the Group’s image and the integrity of its economic and human heritage. Stevanato Group 34 |

Sustainability Report—2021 The specific provisions contained in the Code of Ethics have been reported in specific internal policies and procedures that ensure compliance with the principles and guidelines of the Code of Ethics (e.g., anti-corruption, insider trading, related parties and anti-discrimination). In this regard, it should be noted that the Group also approved an anti-bribery and anti-corruption policy on July 2, 2021, and approved an anti-discrimination policy on December 17, 2021. For further details on these policies please refer to the investors section of the corporate website. Stevanato Group acts in compliance with intellectual, industrial and commercial property rights, as well as with international laws and regulations in order to protect such rights. In 2021, no cases of non-compliance with environmental laws and regulations were registered. Since April 2021, Stevanato Group has adopted a whistleblowing procedure to correctly manage the reporting of any violations and irregularities concerning the Code of Ethics related to Italian Legal Entities. In this context, Stevanato Group ensures that business is conducted in line with fairness, completeness and transparency of information and legitimacy, excluding any form of corruption or favoritism. Employees can report any violations or suspected violations to the Company through a dedicated email address: csr-complian-ce@stevanatogroup.com. The information transmitted is promptly checked and, once the Report has been verified, the case is submitted to the competent corporate department for the application of any disciplinary sanctions or for the activation of contractual termination mechanisms. This whistleblowing procedure is designed to ensure the confidentiality of the person reporting the issue and the information received, as well as its validity. Note that, no grievances as of December 31, 2021, have been sent to the relevant function inbox and, during 2021, no cases of incidents of corruption or human rights violations were recorded in the Group. In accordance with Italian law, Steva-nato Group has introduced an Organizational, Management and Control model for its Italian entities as per Legislative Decree no. 231/01. The management principles envisaged by the Organizational, Management and Control framework are aimed at preventing the commission of crimes by employees, or any other crimes connected to Stevanato Group that may involve the Group’s Italian companies. The Group is currently working to strengthen management systems within the foreign companies to ensure compliance with each local law, taking into consideration the provisions of the Model of Organization, Management and Control pursuant to Legislative Decree 231/01. The parent company, Stevanato Group S.p.A., has set up a Supervisory Body pursuant to Legislative Decree 231/01, responsible for monitoring compliance, operating and updating the Model. A communication channel has been set up at the e-mail address odv.steva-natogroup@stevanatogroup.com, which only members of the Supervisory Board may access to receive reports of any violations or suspected violations of the Model from internal and external subjects. Stevanato Group 35 |

Sustainability Report—2021 A FOCUS ON STEVANATO GROUP RISK MANAGEMENT Risk monitoring and management is an integral part of Stevanato Group’s business model. Risk exposure is managed through careful monitoring carried out by each employee. At the moment, Stevanato Group tackles ESG risks & opportunities in accordance with current legislation and regulations. The main relevant risk categories identified are: • business risks related to activities and critical aspects of the business; • risks related to the efficiency and effectiveness of business operating processes with impact on Group performance; • risks related to human resources management and the effectiveness of the organizational structure; • risks related to financial planning processes and financial reporting activities, management of financial and insurance instruments; • risks related to compliance with national and international laws, regulations and Group policies. As proof of the Group’s ongoing commitment to ethical conduct and integrity in its business, there were no reports and/or complaints received about non-compliance with laws or regula- tions, or legal action taken regarding anti-competitive behavior, anti-trust or monopoly violations either in or out of court in 2021. Stevanato Group 36 |

Stevanato Group and sustainability SG Stevanato Group 2

Sustainability Report—2021| 2.1 Approach to sustainability Stevanato Group aims to align its corporate culture and business operations with relevant Environmental Social and Governance (ESG) elements pursuing a sustainable corporate model. The Group is committed to embedding sustainability values into its policies and practices and to establishing a culture of integrity. SG believes that the challenge and opportunity is to continue growing and supporting its customers through regenerative business innovation, while making a positive impact for the benefit of all, in everything the Company does. The Group considers itself an interdependent and responsible member of the community it operates in and, as such, promotes initiatives and solutions that foster the health and wellbeing of society and the planet as a whole. As a key player in the pharmaceutical and healthcare market, Stevanato Group is focused on developing and strengthening its sustainability practices. As stated in its EHS policy, Stevanato Group aims to protect the environment, to operate under the principles of sustainability on a global level, and to integrate EHS management into all business processes, including the commitment to energy-saving programs and the optimization of natural resources consumption. In addition, Stevanato Group pursues the Life Cycle Perspective of selected products, packaging and processes as part of its corporate Circular Economy innovation program. As such, it strives to improve the environmental and societal impact of its business through the integration of principles such as: (i) Design out waste and pollution; (ii) Keep products and materials in use; (iii) Regenerate natural systems. These sustainable practices can help mitigate impact in areas such as climate- change, biodiversity loss, and pollution. Finally, Stevanato Group fosters Public-Private co-innovation through collaboration with Universities/ Joint Labs to advance education and awareness on such topics. Through a materiality assessment, the Group has identified the ESG issues most relevant to the organization and its stakeholders. The issues considered have a substantial impact on Stevanato Group’s environmental, social and economic performance, or may substantially influence stakeholders’ decisions. Therefore, as required by the Standards of the Global Reporting Initiative (GRI), Stevanato Group has defined and organized the contents of the Sustainability Report to provide disclosure on how the Group manages sustainability by assessing these material issues. Sustainability 38

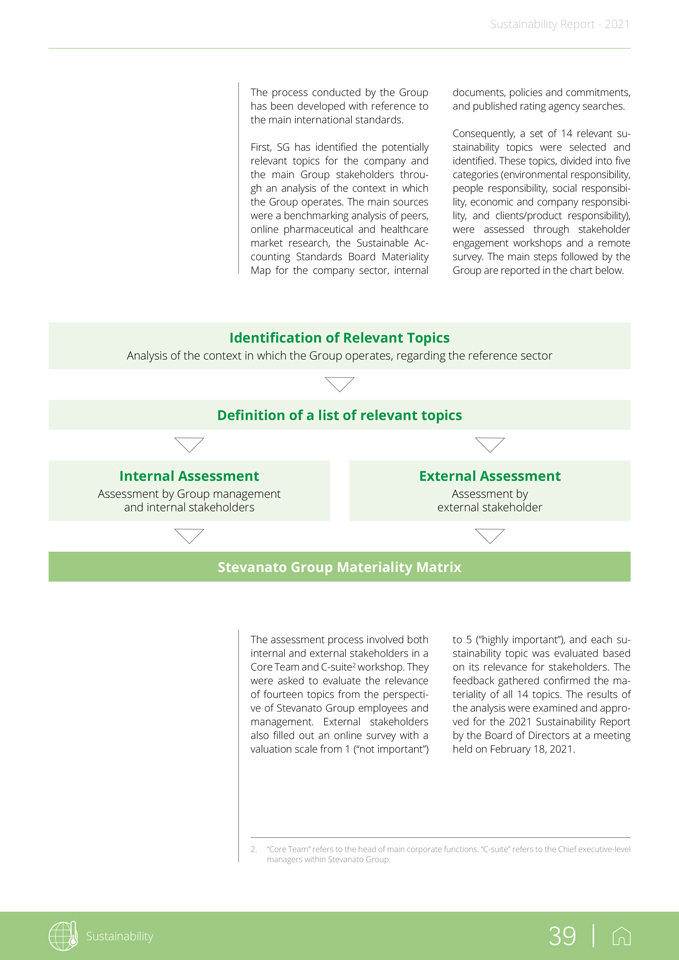

2. “Core Team” refers to the head of main corporate functions. “C-suite” refers to the Chief executive-level managers within Stevanato Group. Sustainability Report—2021 The process conducted by the Group has been developed with reference to the main international standards. First, SG has identified the potentially relevant topics for the company and the main Group stakeholders through an analysis of the context in which the Group operates. The main sources were a benchmarking analysis of peers, online pharmaceutical and healthcare market research, the Sustainable Accounting Standards Board Materiality Map for the company sector, internal documents, policies and commitments, and published rating agency searches. Consequently, a set of 14 relevant sustainability topics were selected and identified. These topics, divided into five categories (environmental responsibility, people responsibility, social responsibility, economic and company responsibility, and clients/product responsibility), were assessed through stakeholder engagement workshops and a remote survey. The main steps followed by the Group are reported in the chart below. Identification of Relevant Topics Analysis of the context in which the Group operates, regarding the reference sector Definition of a list of relevant topics Internal Assessment External Assessment Assessment by Group management Assessment by and internal stakeholders external stakeholder Stevanato Group Materiality Matrix The assessment process involved both internal and external stakeholders in a Core Team and C-suite2 workshop. They were asked to evaluate the relevance of fourteen topics from the perspective of Stevanato Group employees and management. External stakeholders also filled out an online survey with a valuation scale from 1 (“not important”) to 5 (“highly important”), and each sustainability topic was evaluated based on its relevance for stakeholders. The feedback gathered confirmed the materiality of all 14 topics. The results of the analysis were examined and approved for the 2021 Sustainability Report by the Board of Directors at a meeting held on February 18, 2021. Sustainability 39 |

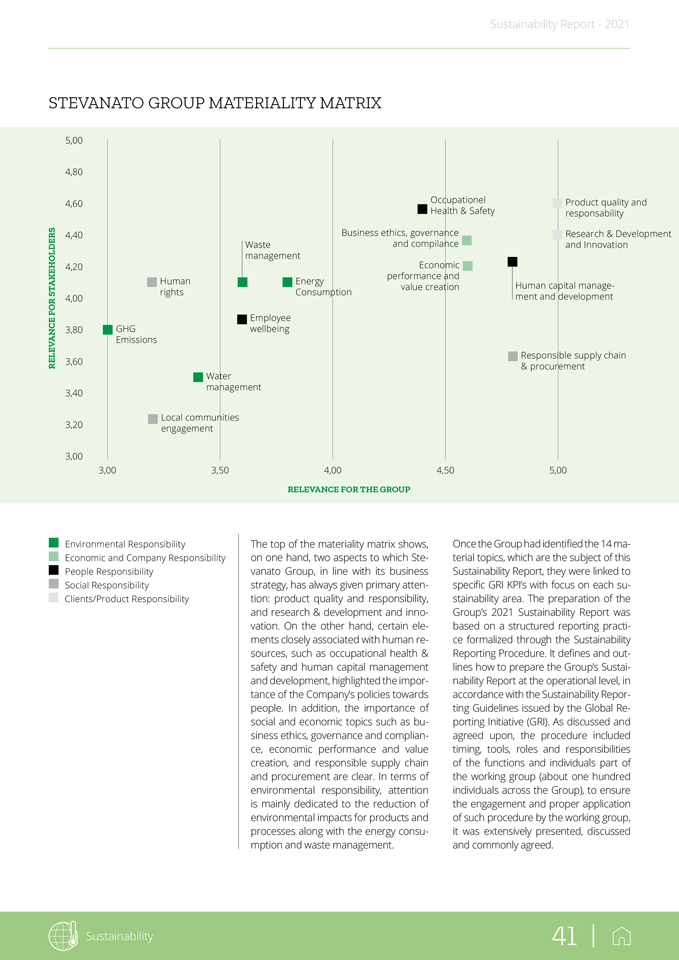

Sustainability Report—2021 1 2 3 4 5 Research & Business ethics, Human capital Product quality Occupational Development governance and management and and responsibility Health & Safety and Innovation compliance development 14 6 Economic Local performance communities and value engagement MATERIAL TOPIC creation FOR SUSTAINABILITY REPORT 2021 13 7 Responsible GHG supply chain & Emissions procurement 12 11 10 9 8 Water Human Employee Waste Energy management rights wellbeing management Consumption The materiality assessment allowed the Group to identify 14 topics across five areas: environmental responsibility, people responsibility, social responsibility, economic and company responsibility and clients/product responsibility. These are considered highly relevant for Stevanato Group, as illustrated in the materiality matrix below. Sustainability 40 |

Sustainability 41 | Sustainability Report—2021 STEVANATO GROUP MATERIALITY MATRIX 5,00 4,80 4,60 Occupationel Product quality and Health & Safety responsability 4,40 Business ethics, governance Research & Development Waste and compilance and Innovation management Economic 4,20 performance and Human Energy Human capital manage-value creation STAKEHOLDERS rights Consumption FOR 4,00 ment and development Employee 3,80 GHG wellbeing Emissions Responsible supply chain RELEVANCE 3,60 & procurement Water management 3,40 Local communities 3,20 engagement 3,00 3,00 3,50 4,00 4,50 5,00 RELEVANCE FOR THE GROUP Environmental Responsibility Economic and Company Responsibility People Responsibility Social Responsibility Clients/Product Responsibility The top of the materiality matrix shows, on one hand, two aspects to which Ste-vanato Group, in line with its business strategy, has always given primary attention: product quality and responsibility, and research & development and innovation. On the other hand, certain elements closely associated with human resources, such as occupational health & safety and human capital management and development, highlighted the importance of the Company’s policies towards people. In addition, the importance of social and economic topics such as business ethics, governance and compliance, economic performance and value creation, and responsible supply chain and procurement are clear. In terms of environmental responsibility, attention is mainly dedicated to the reduction of environmental impacts for products and processes along with the energy consumption and waste management. Once the Group had identified the 14 material topics, which are the subject of this Sustainability Report, they were linked to specific GRI KPI’s with focus on each sustainability area. The preparation of the Group’s 2021 Sustainability Report was based on a structured reporting practice formalized through the Sustainability Reporting Procedure. It defines and outlines how to prepare the Group’s Sustainability Report at the operational level, in accordance with the Sustainability Reporting Guidelines issued by the Global Reporting Initiative (GRI). As discussed and agreed upon, the procedure included timing, tools, roles and responsibilities of the functions and individuals part of the working group (about one hundred individuals across the Group), to ensure the engagement and proper application of such procedure by the working group, it was extensively presented, discussed and commonly agreed.

Sustainability Report—2021 1 Product quality and responsibility 2 Research & Development and Innovation 3 Occupational Health & Safety 4 Business ethics, governance and compliance 5 Human capital management and development 6 Economic performance and value creation 7 Economic performance and value creation 8 Energy Consumption 9 Waste management 10 Employee wellbeing 11 Human rights 12 Water management 13 GHG Emissions 14 Local communities’ engagement Sustainability 42 |

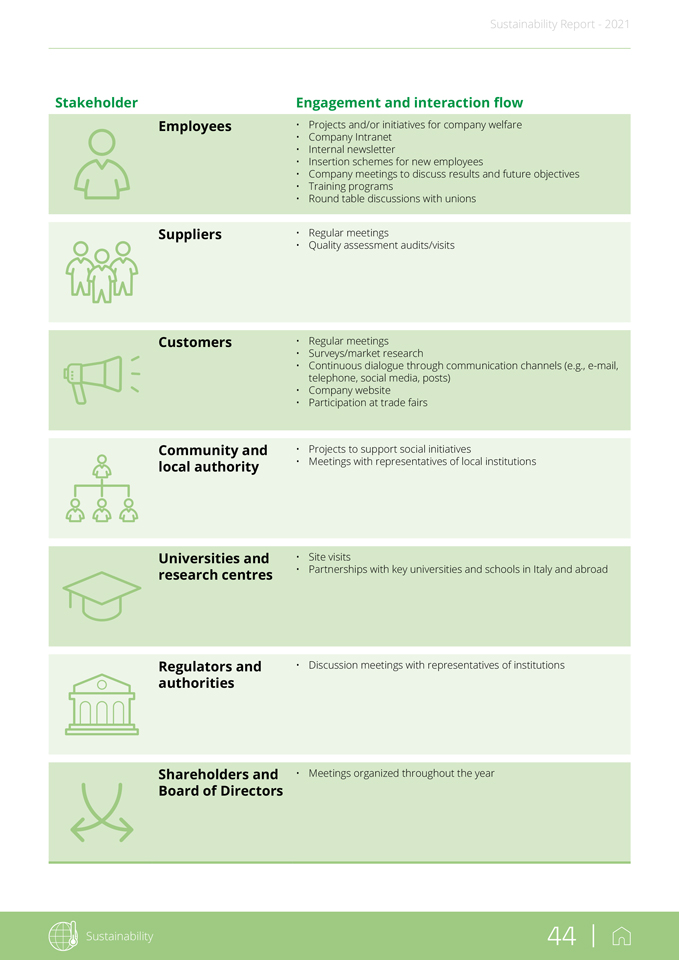

tical issues emerged from stakeholder engagement activities carried out by Group companies. The following figure provides an overview of Stevanato’s seven most relevant stakeholder categories based on an in-depth analysis of the reference sector (peers and customers) carried out during the materiality analysis. Stevanato Group adopts practices that encourage dialogue and involvement with all stakeholder categories. Engagement is considered an essential element of the Group’s sustainability strategy and is directly correlated with the Group’s medium and long-term success. The main channels of dialogue and interaction are summarized below. The methods and frequency of stakeholder involvement vary according to the issues and opportunities subject to discussion during the year. Employes Shareholders and Board of Directors Regulators and authority Universities and research centres Community and local authority Customers Suppliers Finally, it is important to note that the procedure requires correct and compliant GRI KPIs associated with the involved functions and is coordinated by the Process Owner (Chief Financial Officer) and the Deputy Process Owner (responsible for the duties delegated by the Process Owner), as per assignment by the Board of Directors. Stevanato Group has also aligned its material topics with 15 of the 17 Sustainable Development Goals (SDGs) defined by the action program of the 193 UN member Countries. Below is a table showing the connection between Stevanato material topics and UN Sustainable Development Goals (SDGs). The Group has adopted flexible and diversified practices to share present and future Group development strategies with its main stakeholders. No cri-

Sustainability Report—2021 Stakeholder Employees Suppliers Customers Community and local authority Universities and research centres Regulators and authorities Shareholders and Board of Directors Engagement and interaction flow • Projects and/or initiatives for company welfare • Company Intranet • Internal newsletter • Insertion schemes for new employees • Company meetings to discuss results and future objectives • Training programs • Round table discussions with unions • Regular meetings • Quality assessment audits/visits • Regular meetings • Surveys/market research • Continuous dialogue through communication channels (e.g., e-mail, telephone, social media, posts) • Company website • Participation at trade fairs • Projects to support social initiatives • Meetings with representatives of local institutions • Site visits • Partnerships with key universities and schools in Italy and abroad • Discussion meetings with representatives of institutions • Meetings organized throughout the year Sustainability 44 |

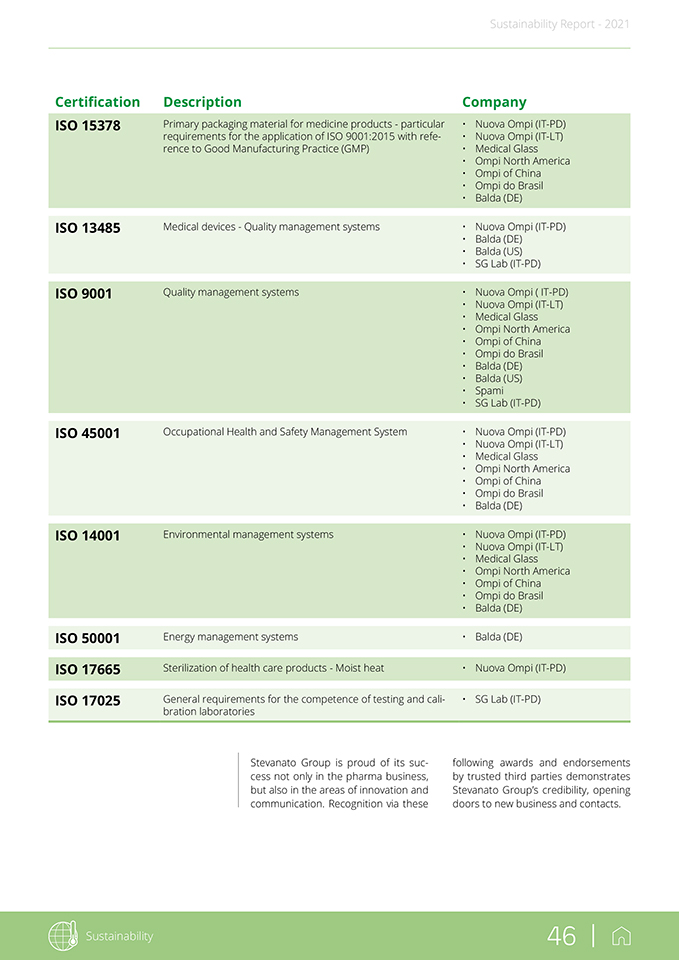

Sustainability Report—2021 2.2 Certifications and awards As part of SG’s continuous efforts to improve its processes, the Group aims to meet leading standards in the field, both in terms of industrial production and product sales, while minimizing the risks to the environment, health and safety in the workplace. This commitment is outlined in the following table, showing the Group’s compliance with the highest standards of certification. Sustainability 45 |

following awards and endorsements by trusted third parties demonstrates Stevanato Group’s credibility, opening doors to new business and contacts. Certification Description Company ISO 15378 Primary packaging material for medicine products—particular • Nuova Ompi (IT-PD) requirements for the application of ISO 9001:2015 with refe- • Nuova Ompi (IT-LT) rence to Good Manufacturing Practice (GMP) • Medical Glass • Ompi North America • Ompi of China • Ompi do Brasil • Balda (DE) ISO 13485 Medical devices—Quality management systems • Nuova Ompi (IT-PD) • Balda (DE) • Balda (US) • SG Lab (IT-PD) ISO 9001 Quality management systems • Nuova Ompi ( IT-PD) • Nuova Ompi (IT-LT) • Medical Glass • Ompi North America • Ompi of China • Ompi do Brasil • Balda (DE) • Balda (US) • Spami • SG Lab (IT-PD) ISO 45001 Occupational Health and Safety Management System • Nuova Ompi (IT-PD) • Nuova Ompi (IT-LT) • Medical Glass • Ompi North America • Ompi of China • Ompi do Brasil • Balda (DE) ISO 14001 Environmental management systems • Nuova Ompi (IT-PD) • Nuova Ompi (IT-LT) • Medical Glass • Ompi North America • Ompi of China • Ompi do Brasil • Balda (DE) ISO 50001 Energy management systems • Balda (DE) ISO 17665 Sterilization of health care products—Moist heat • Nuova Ompi (IT-PD) ISO 17025 General requirements for the competence of testing and cali- • SG Lab (IT-PD) bration laboratories Stevanato Group is proud of its success not only in the pharma business, but also in the areas of innovation and communication. Recognition via these

MOST IMPORTANT AWARDS ACHIEVED The Pharma Innovation Awards are a celebration of technologies contributing to advancements in risk reduction, product quality improvement and manufacturing efficiency. The prize awarded by Pharma Manufacturing acknowledges the investment pharmaceutical equipment vendors put into developing and improving their products. The award is a tribute to Stevanato Group’s ability to listen to the needs of the market and its customers, distinguishing itself as a leader in equipment and technology. In 2018, Pharma Manufacturing recognized that LDP (Low Delamination Propensity) Vials from Ompi (part of Stevanato Group), offered minimized delamination propensity, reducing the risk of drug product recalls. In 2021, Stevanato Group was recognized as a winner of Pharma Manufacturing’s Pharma Innovation Award for its Artificial Intelligence-ready (AI) Vision Robot Unit (VRU). A robotic human-like inspection unit, the VRU is a perfect match for the factory of the future, combining human-like flexibility with machine learning capabilities. In addition, SG Vision AI, Stevanato Group’s Artificial Intelligence-based platform for visual inspection machines, was nominated among the top technologies in the shortlist of Innovation Awards 2021 powered by “The Medicine Maker”. Contamination Lab, also present in the Veneto Region, is an open-innovation program that fosters entrepreneurial culture in young talent through the development of market-based innovative projects. In 2021, C_Lab hosted a competition in which 12 companies from different industries took part, including 230 candidates, 80 participants and 12 teams of talent. Stevanato Group supported a team as part of the corporate Circular Economy innovation program, where the purpose was to improve the environmental impact of glass-based End-Of-Life Drug Containment Solutions. The team won first prize in the competition for its achievement in identifying and creating upcycling concepts for the End Of Life of glass-based products. On August 19, 2021, the Slovak Chamber of Commerce and Industry awarded our Medical Glass plant in Slovakia for its contribution to economic development and business in the Slovak Republic. The award recognized how SG actively involves its stakeholders in the continuous improvement of processes focused on responsible development in the communities in which we operate. Launched in 1997 by Pharmapack, the Pharmapack Awards celebrate the latest innovations from packaging companies within the drug, medical device, health product and veterinary drug sectors. The Pharmapack Awards recognize innovations that have improved drug efficacy and user safety, or reduced environmental impact. In 2019, the cartridge-based wearable device designed by Stevanato Group won the prize for the Best Innovation in Drug Delivery Device.

Open Innovation is one of the pillars of the Smau company. The Innovation Awards are intended to be a recognition of companies and public bodies and aim to share and spread good practices. Stevanato Group received the award in 2019 for its “SYN Here” geo-mapping software designed by the I-Digital department. The intelligence platform mapped specific locations, internal/external spaces and objects in SG plants, building an interactive component into company information processes. By creating a virtual twin of the plant, the digital model helped shed light on critical infrastructure attributes such as compliance and safety issues.

2.3 Participation in organizations and associations Stevanato Group cooperates with an extensive network of trade associations and organizations, facilitating the exchange of ideas, knowledge and different points of view.

Founded in 1890, the Drug, Chemical & Associated Technologies Association, Inc. (DCAT) is a not-for-profit, corporate member-supported and volunteer-led global business development association for companies engaged in the Bio/Pharmaceutical manufacturing value chain. DCAT has been providing a life-long collegial community for its Member Companies and their representative for over 130 years. DCAT creates objective, expert-driven education programs and informational services, so its Member Companies can easily gain insight into industry market trends, best practices and the issues affecting the industry. The Parenteral Drug Association (PDA) is the leading global provider of science, technology and regulatory information. The PDA creates awareness and understanding of important issues facing the pharmaceutical and biopharmaceutical community and delivers high-quality, relevant education to the industry. Since its founding in 1946 as a nonprofit organization, PDA has been committed to developing scientifically sound, practical technical information and expertise to advance pharmaceutical/biopharmaceutical manufacturing science and regulation so members can better serve patients. The International Society for Pharmaceutical Engineering is the world’s largest not-for-profit association leading scientific, technical and regulatory advancement throughout the entire pharmaceutical lifecycle. ISPE is the global industry leader in connecting pharmaceutical knowledge to manufacturing and supply chain innovation, operational excellence and regulatory insights to enhance industry efforts to develop, manufacture and reliably deliver quality medicines to patients. MassBio is an American not-for-profit organization founded in 1985 that represents and provides services and support for the #1 life sciences cluster in the world. Mas-sBio’s mission is to advance Massachusetts’ leadership in the life sciences to grow the industry, add value to the healthcare system and improve patient lives. They represent the premier global life sciences and healthcare hub, with 1,400+ members dedicated to preventing, treating, and curing diseases through transformative science and technology that brings value and hope to patients. Founded in 1996, the Massachusetts Medical Device Industry Council (MassME-DIC) is the largest regional MedTech association in the United States with over 300 members. MassMEDIC is the primary source of advocacy, information and support to the region’s MedTech manufacturers, suppliers and associated non-profit groups. It advocates for sound public policy that supports innovation and fosters a community built on a shared purpose: saving and improving the lives of patients everywhere through medical technology.

The ICG (International Commission on Glass) is a non-profit international Society of national scientific and technical organizations with particular interest in glass science and technology. It was founded in 1933 and has grown to become the recognized worldwide organization in the field of glass with 37 current members, bringing together the world’s most respected universities, scientific institutions and companies in the glass industry. The aim of ICG is to promote and stimulate understanding and cooperation between glass experts in the fields of science and technology as well as art, history and education. The China National Pharmaceutical Packaging Association (CNPPA) is a national non-profit organization, formerly known as the National Pharmaceutical Packaging Technology Center. It was set up in Guangzhou in June 1980 and was officially renamed China National Pharmaceutical Packaging Association in November 1991 with the approval of the Ministry of Civil Affairs. The association has nearly 500 members.

Economic sustainability 3

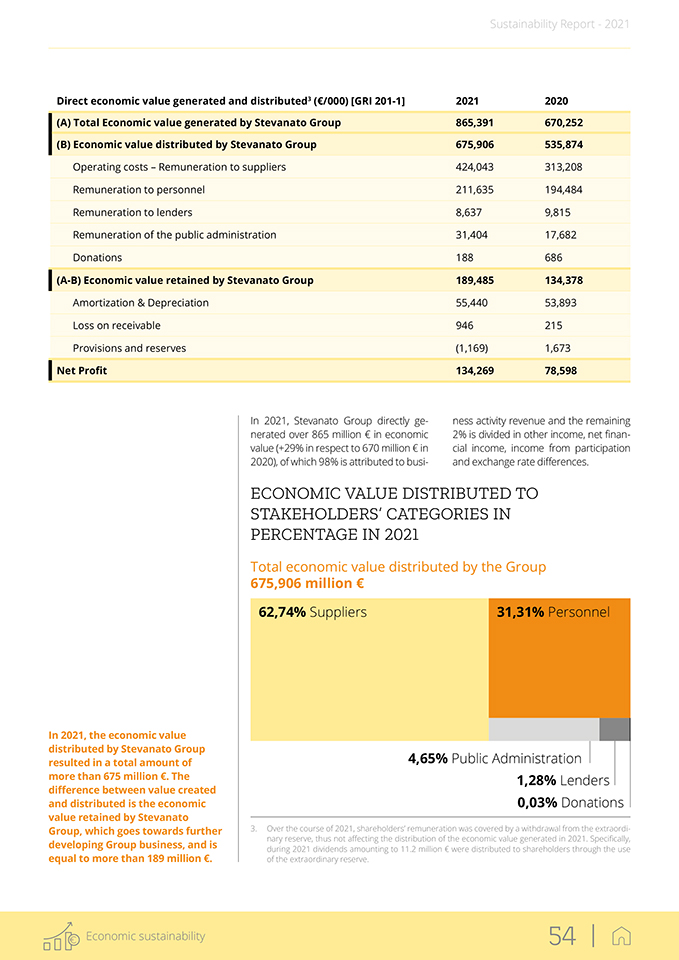

Economic sustainability 3.1 Stakeholder value creation The creation and distribution of direct economic value demonstrates how Stevanato Group has created wealth for its stakeholders, as shown by the figures in the Direct economic value generated and distributed (EVG&D) chart below. Founded on an accrual basis, it includes the basic components from Profit and Loss (P&L) statements for the global operations in accordance with GRI Disclosure. Throughout Stevanato’s operational activities, the Group creates value for a wide variety of stakeholders, including: • Suppliers in terms of operating costs; • Personnel by considering employee wages and benefits as total payroll; • Lenders looking at financial charges; • Public administration with payments to governments such as taxes; • Communities including donations, sponsorships and collaboration.

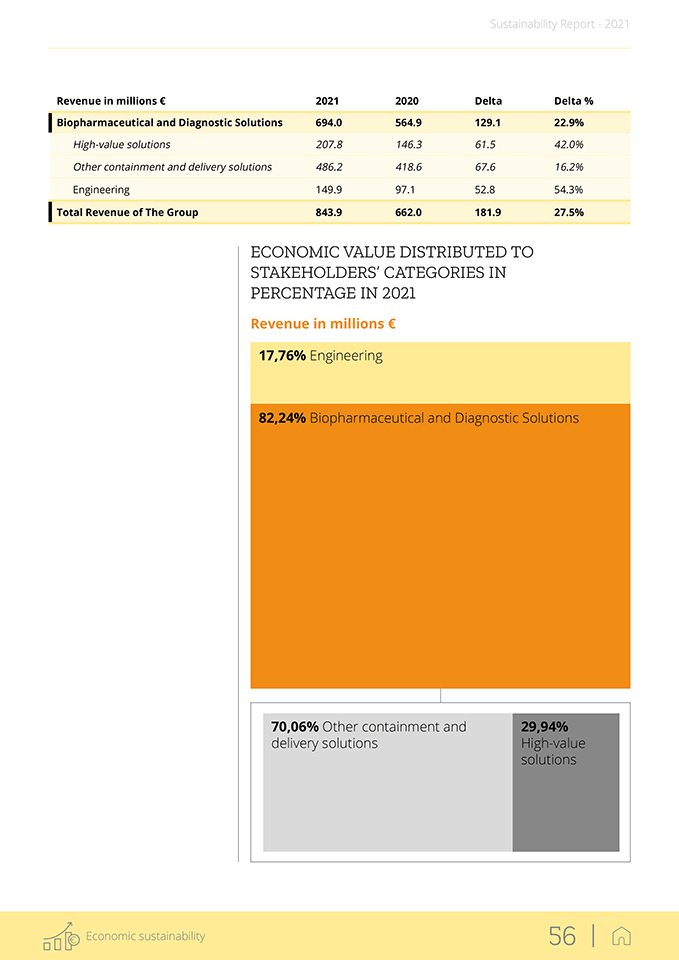

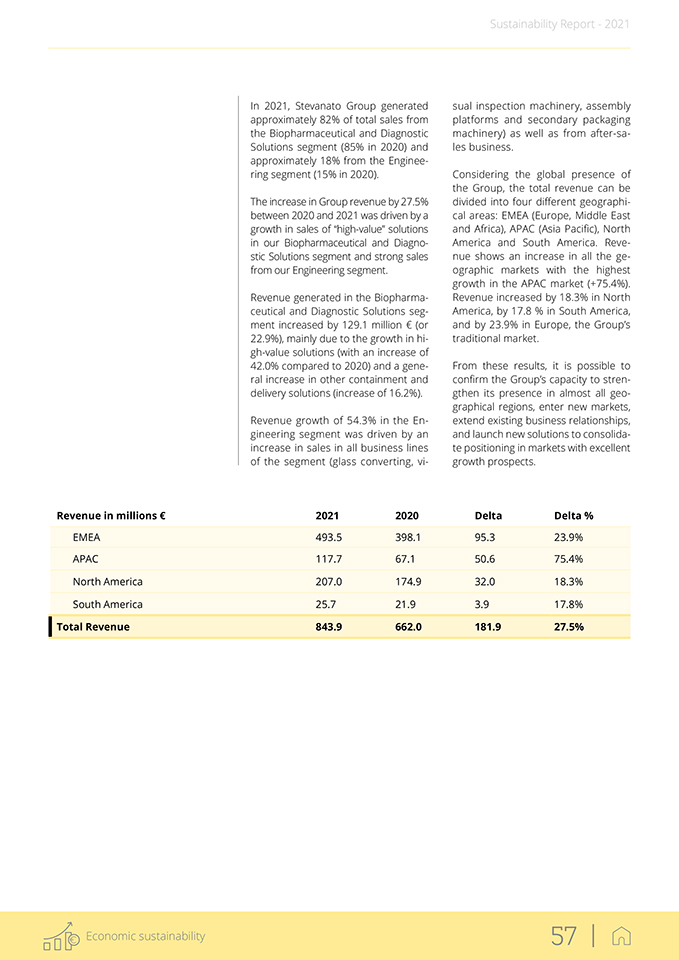

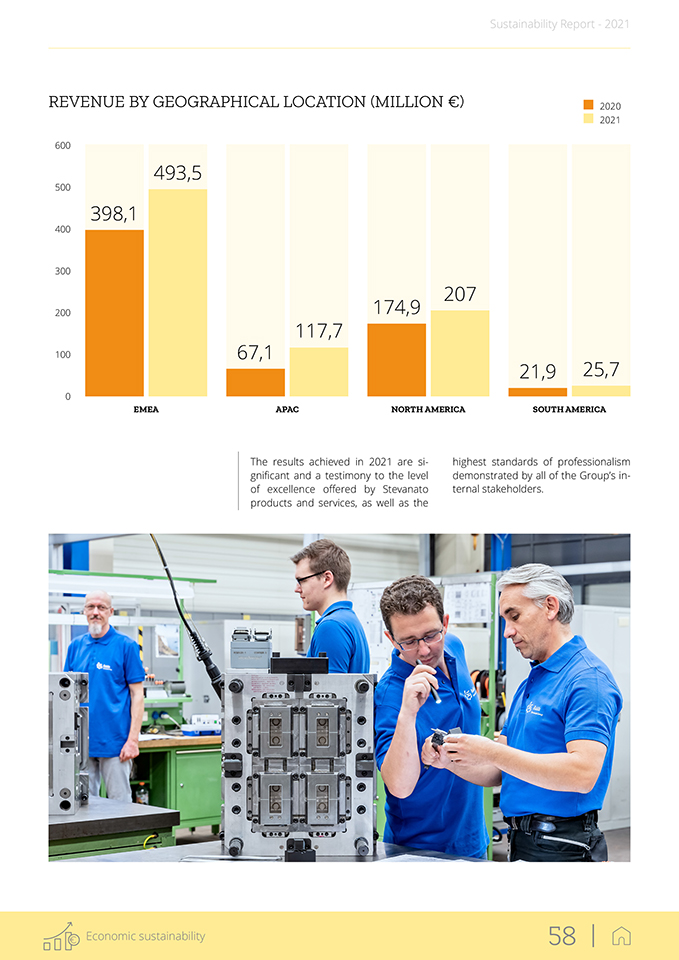

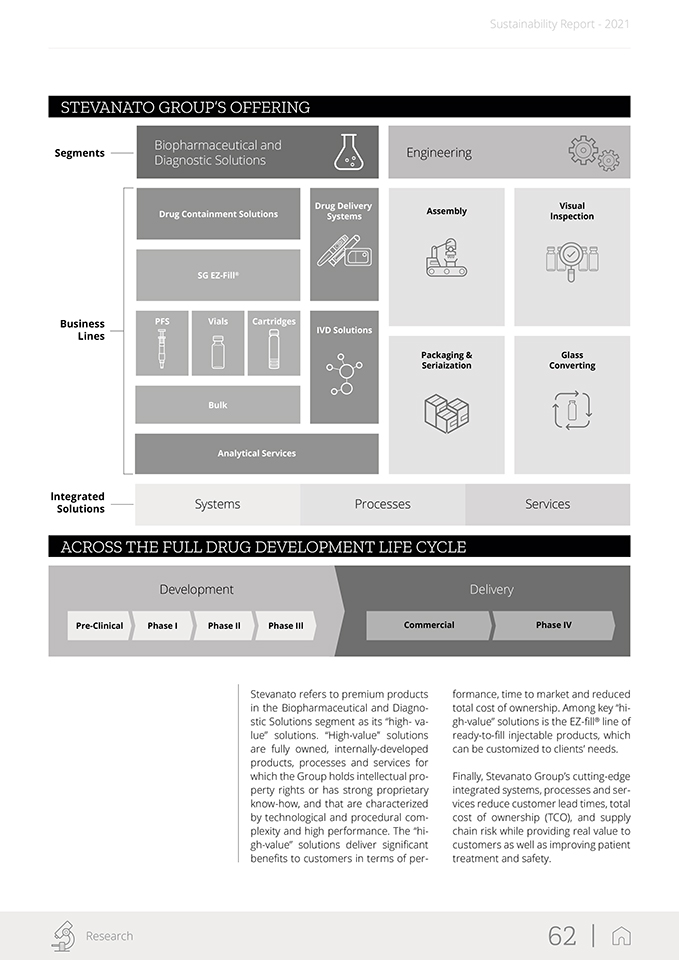

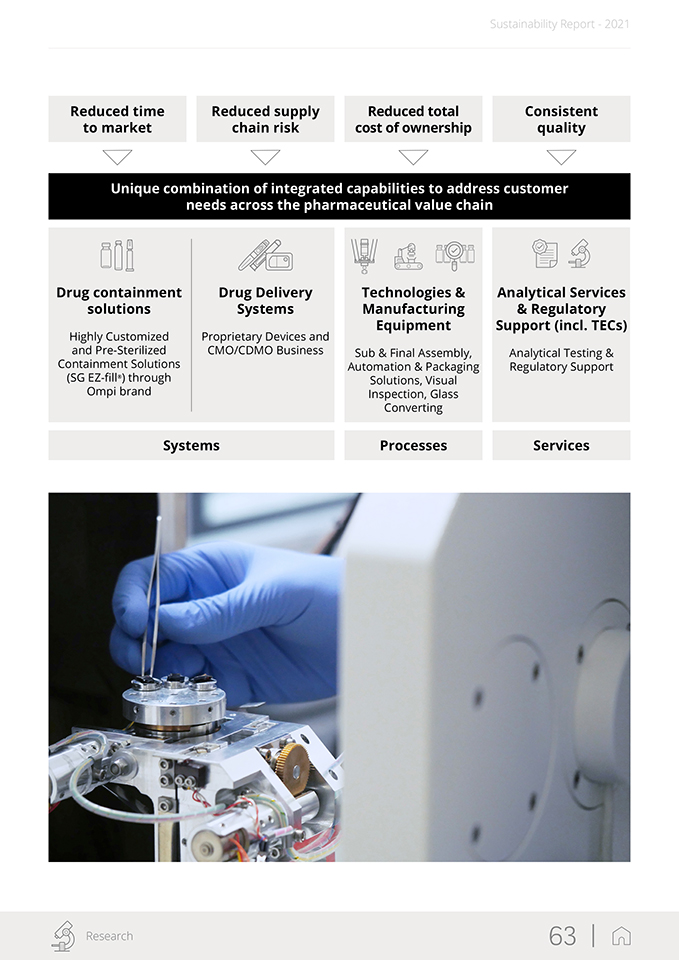

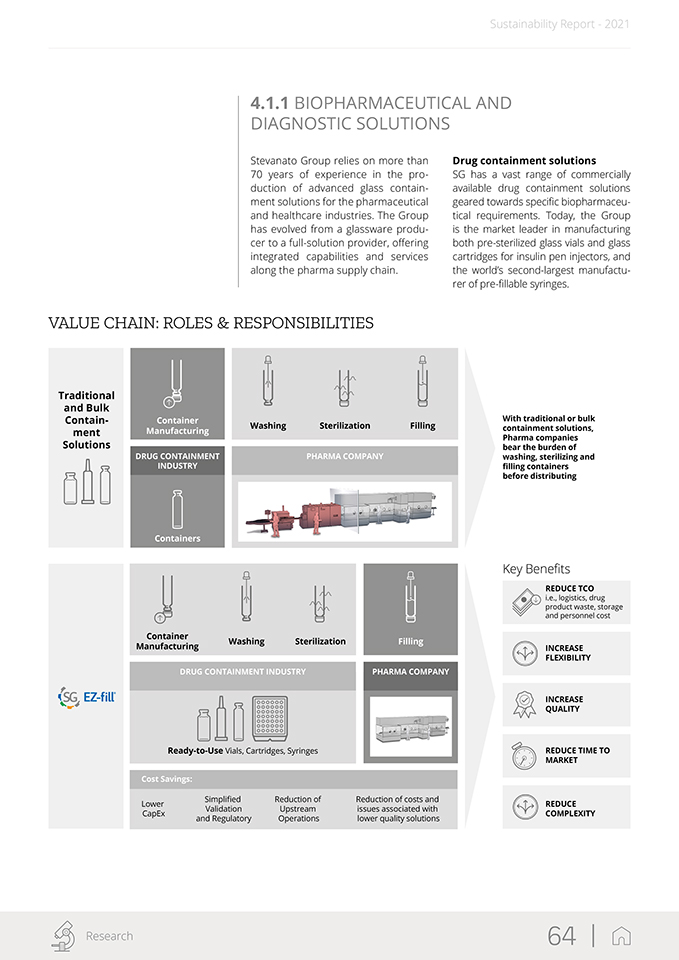

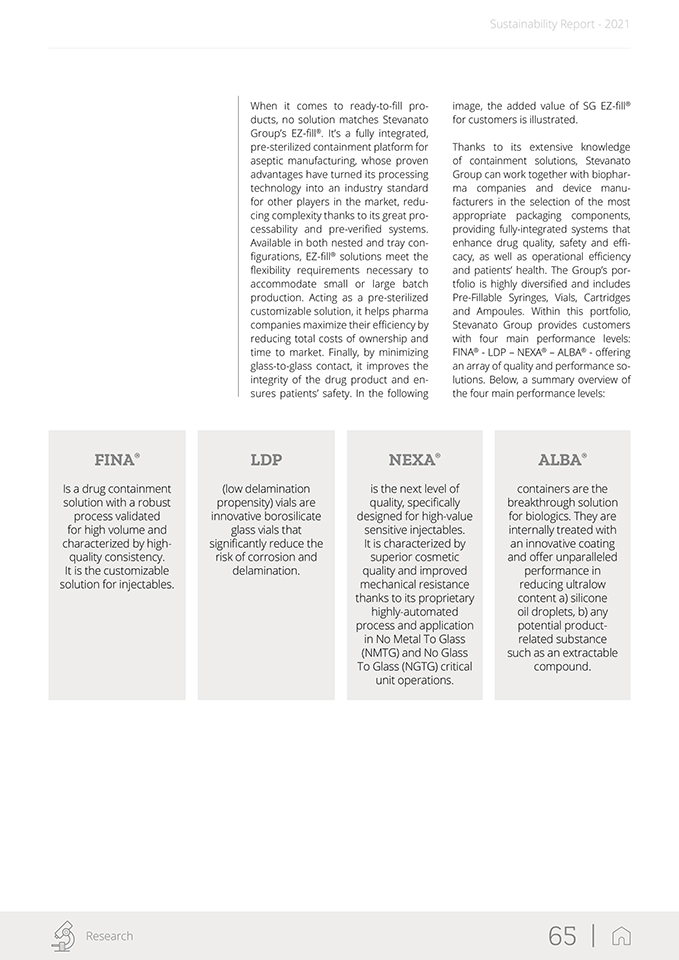

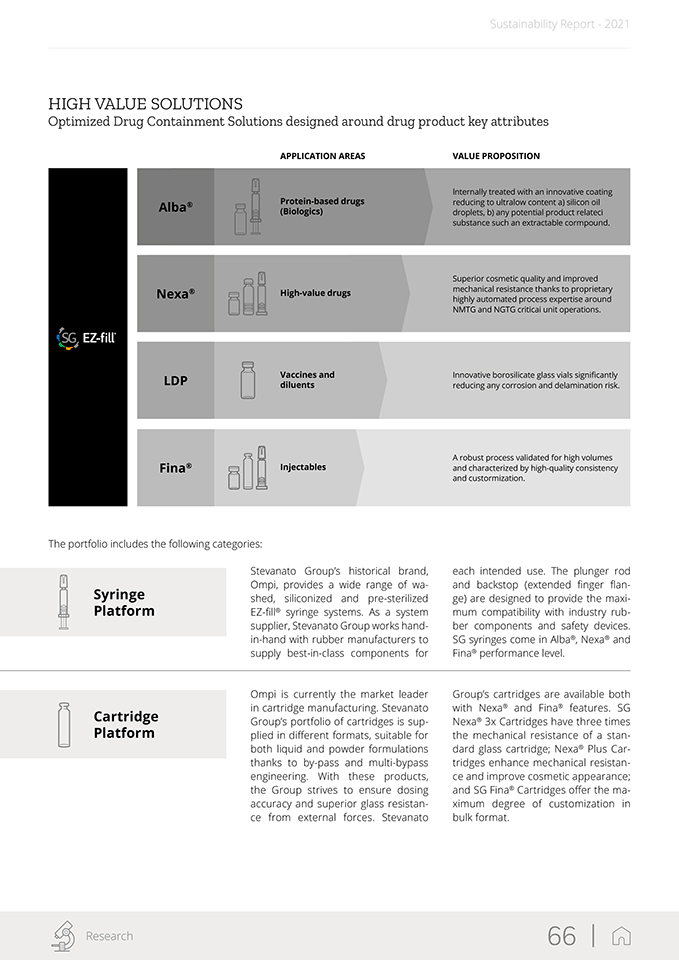

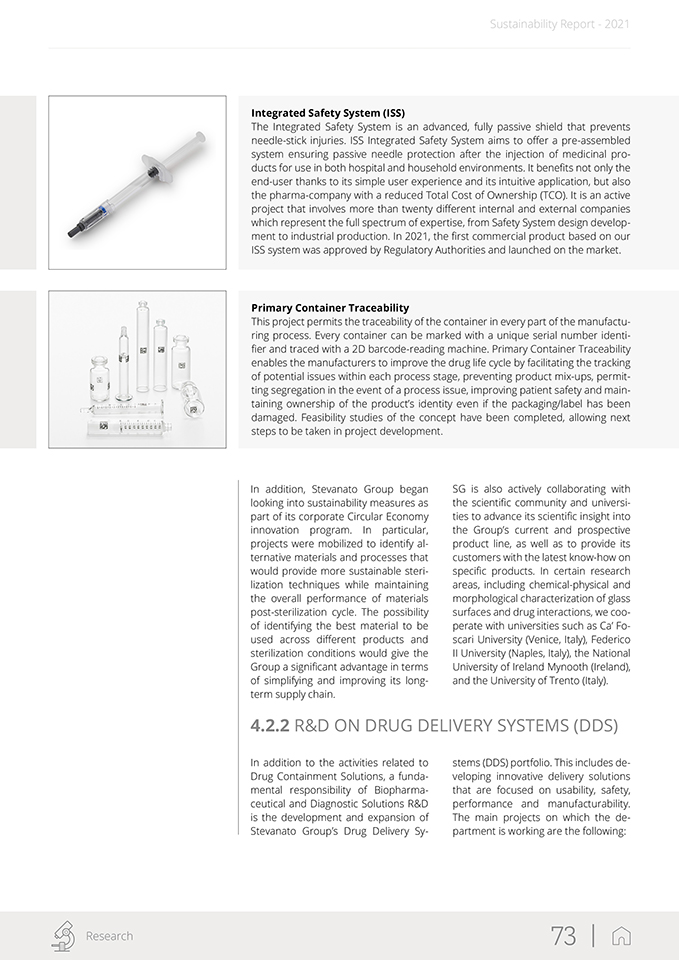

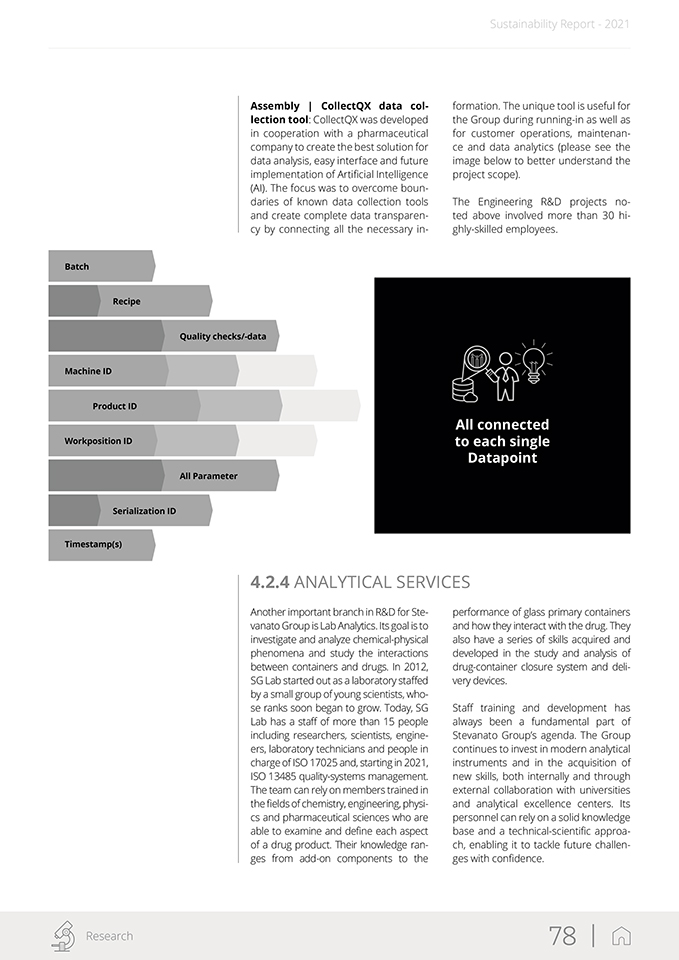

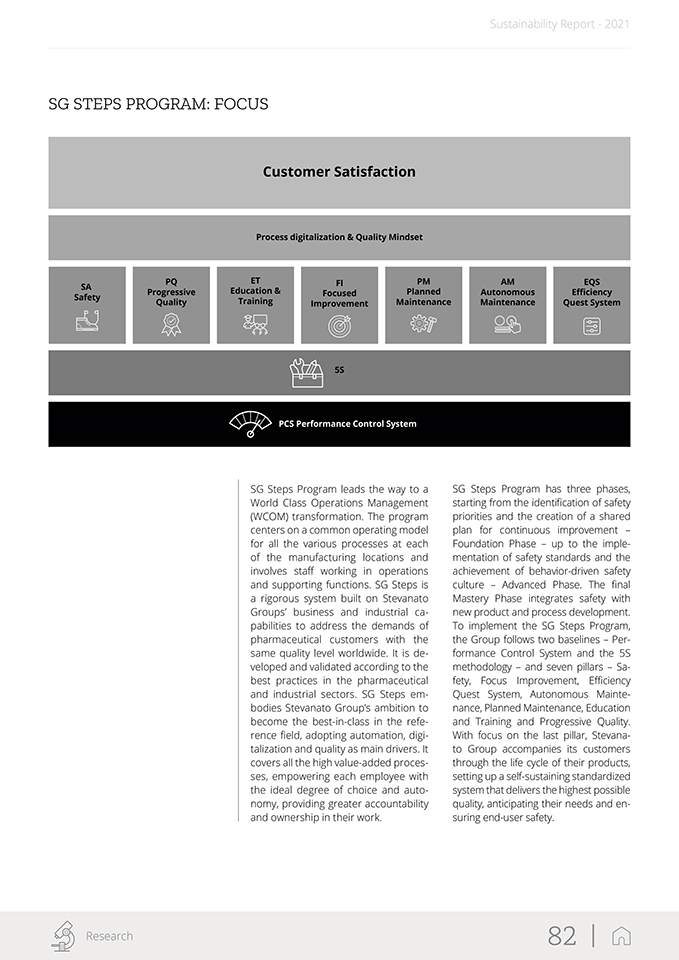

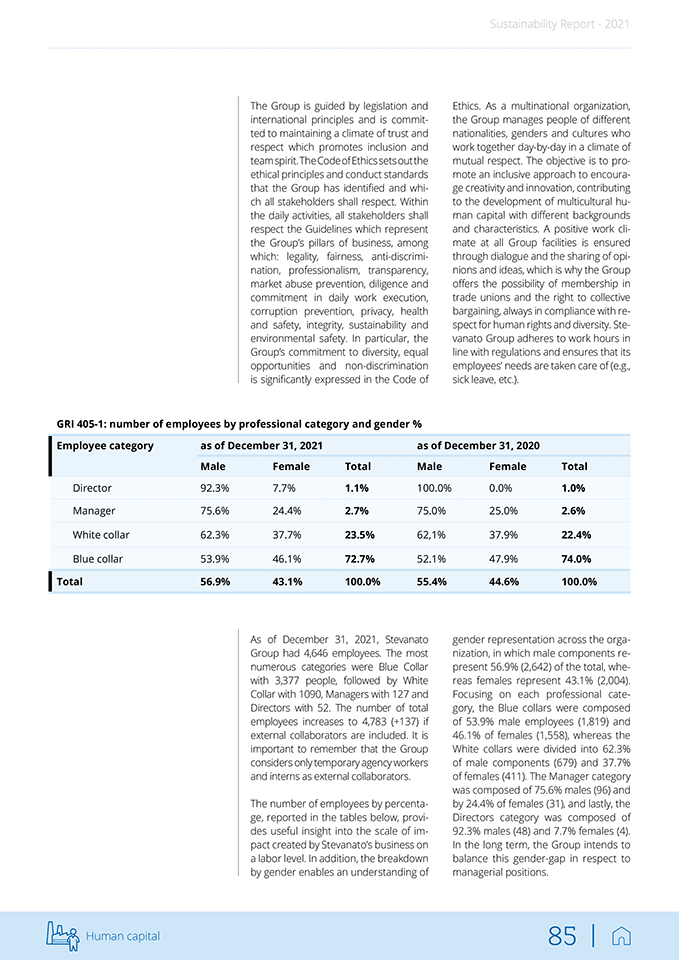

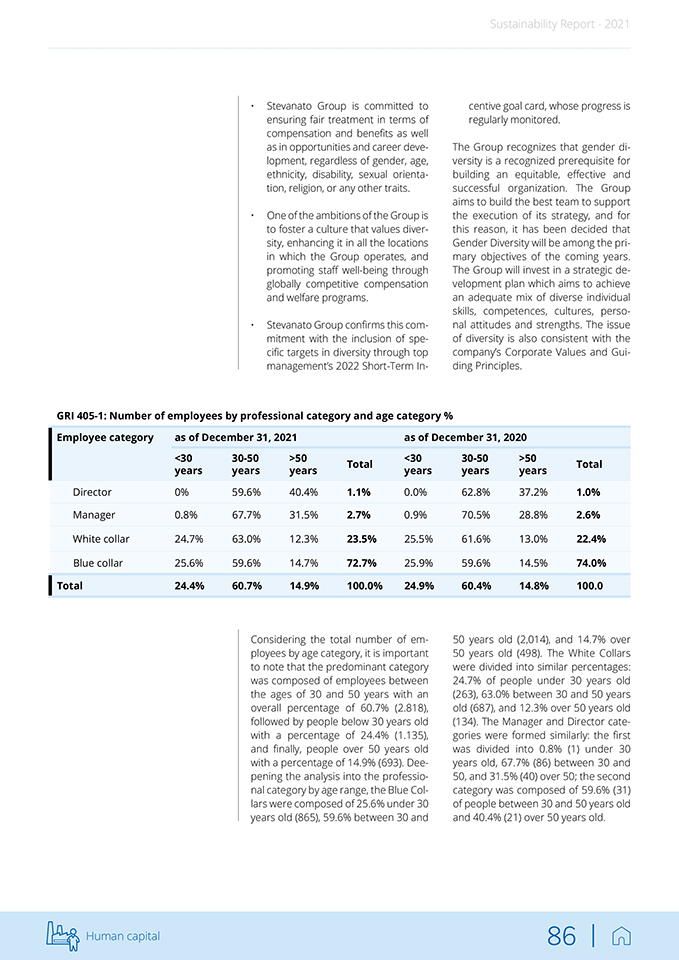

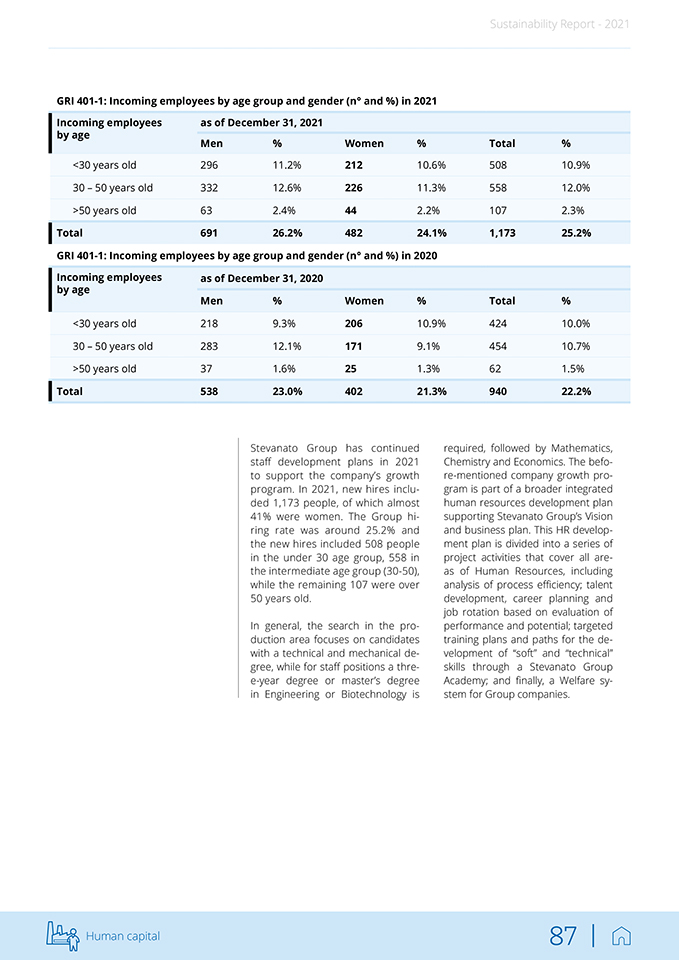

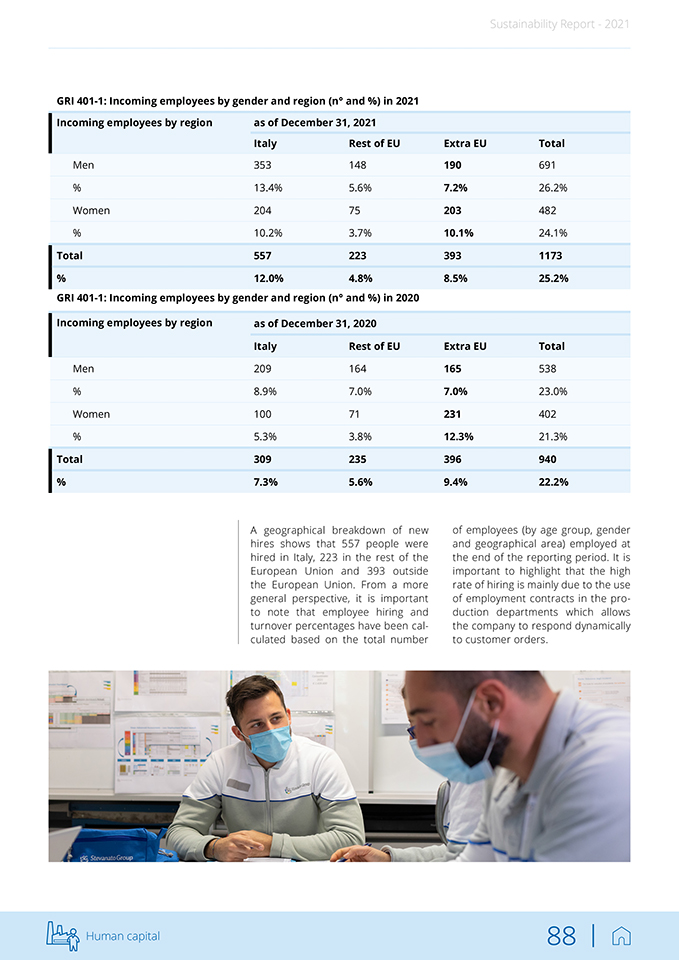

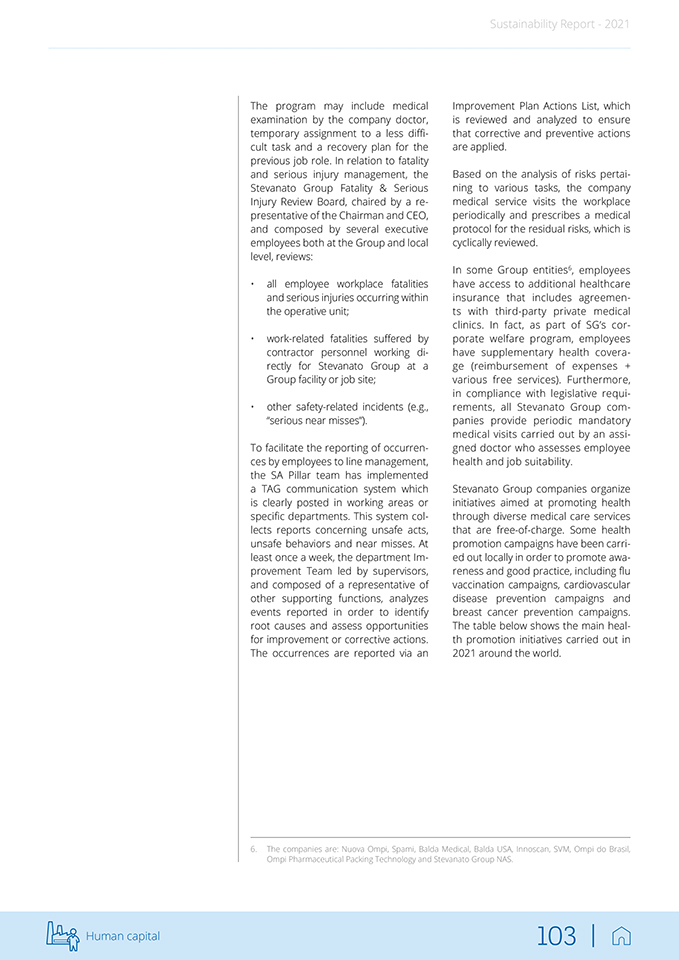

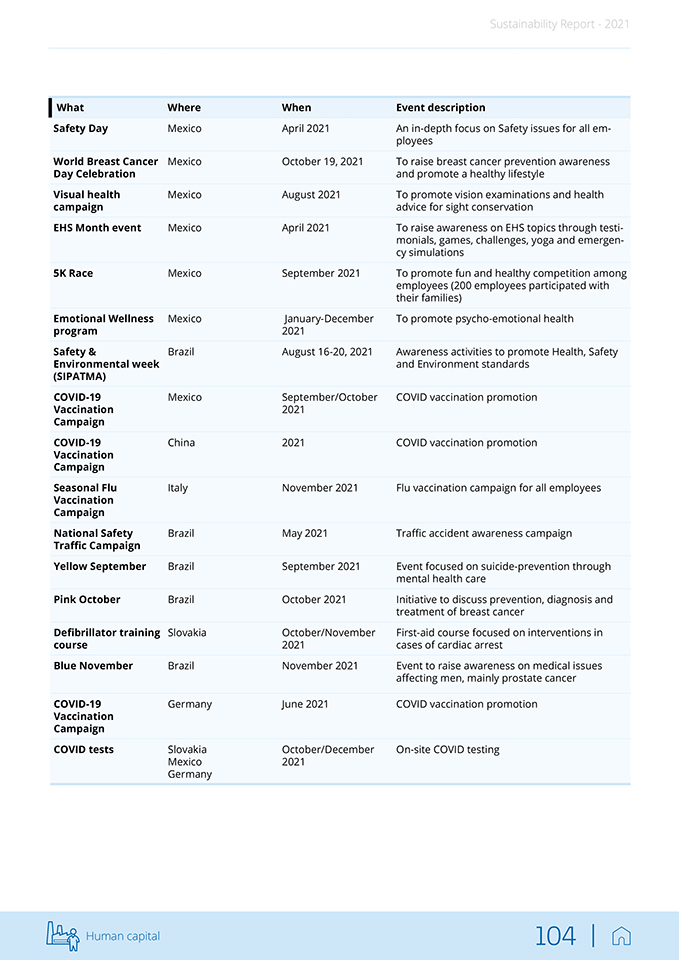

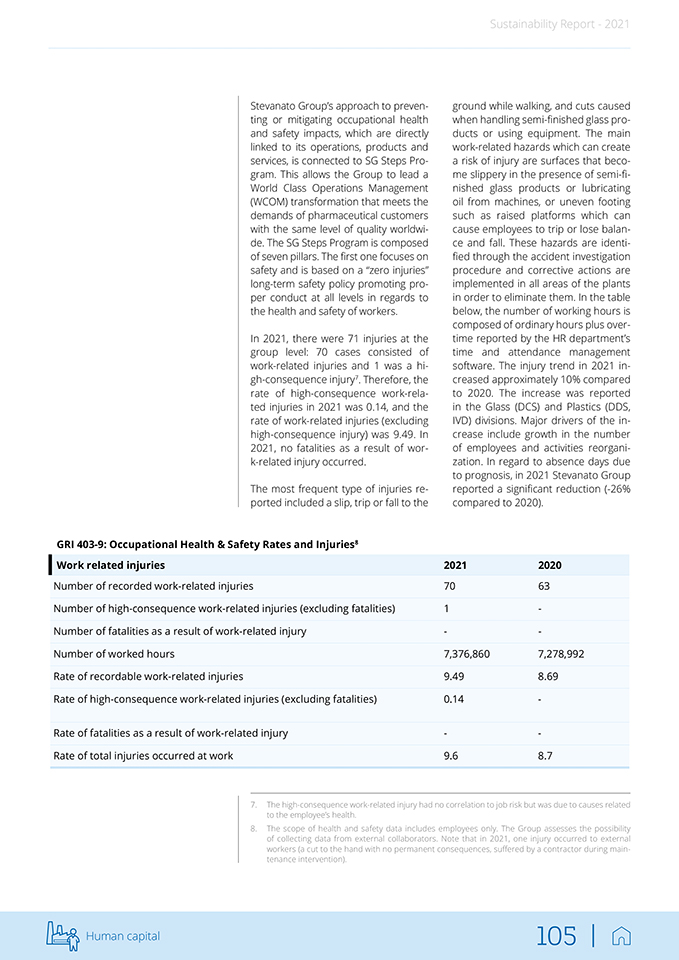

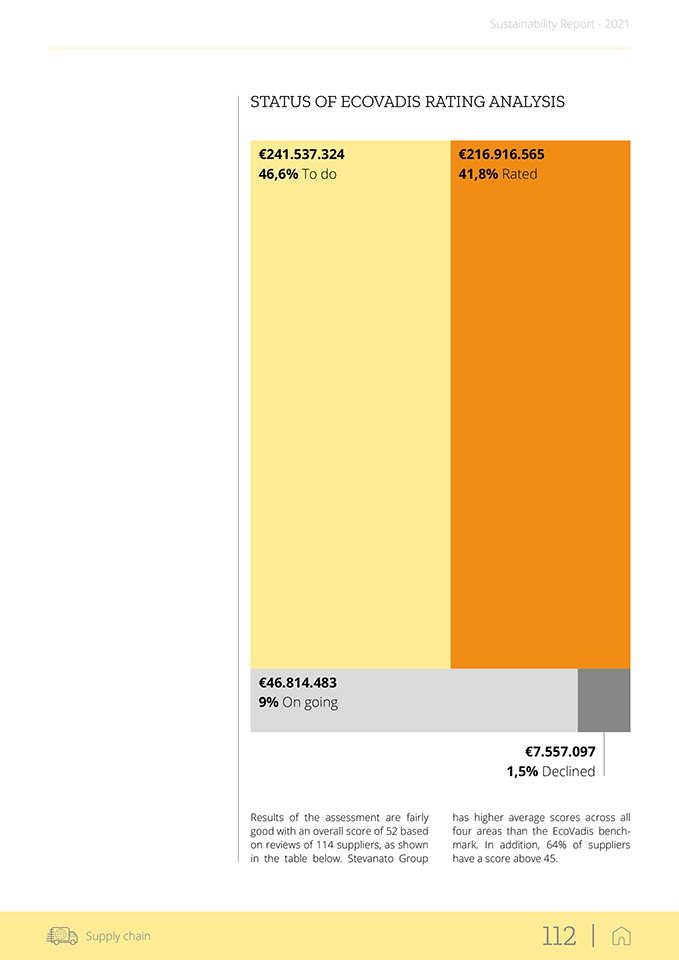

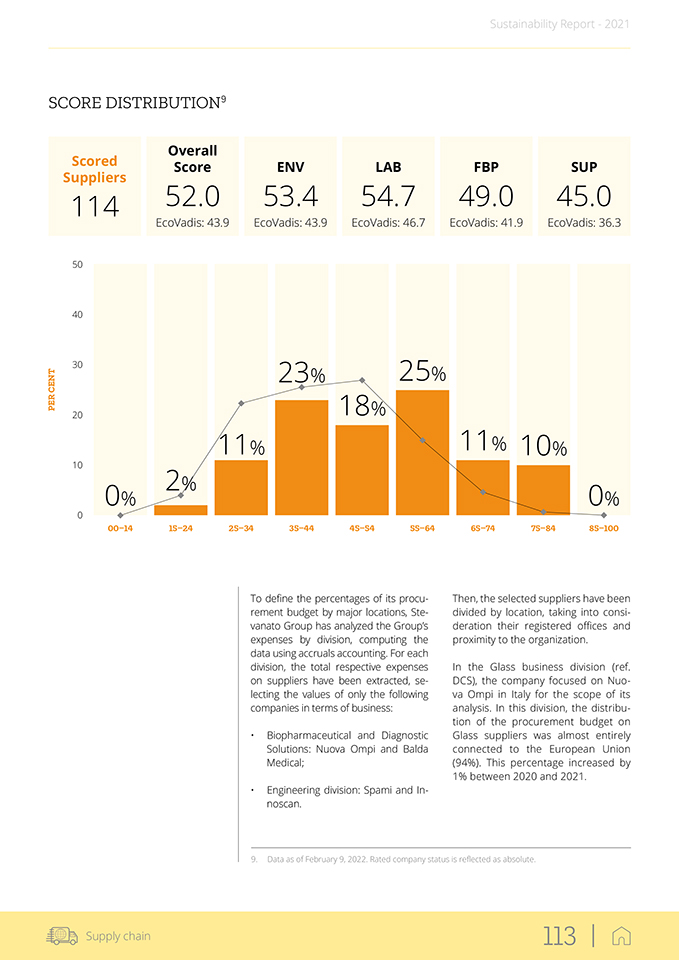

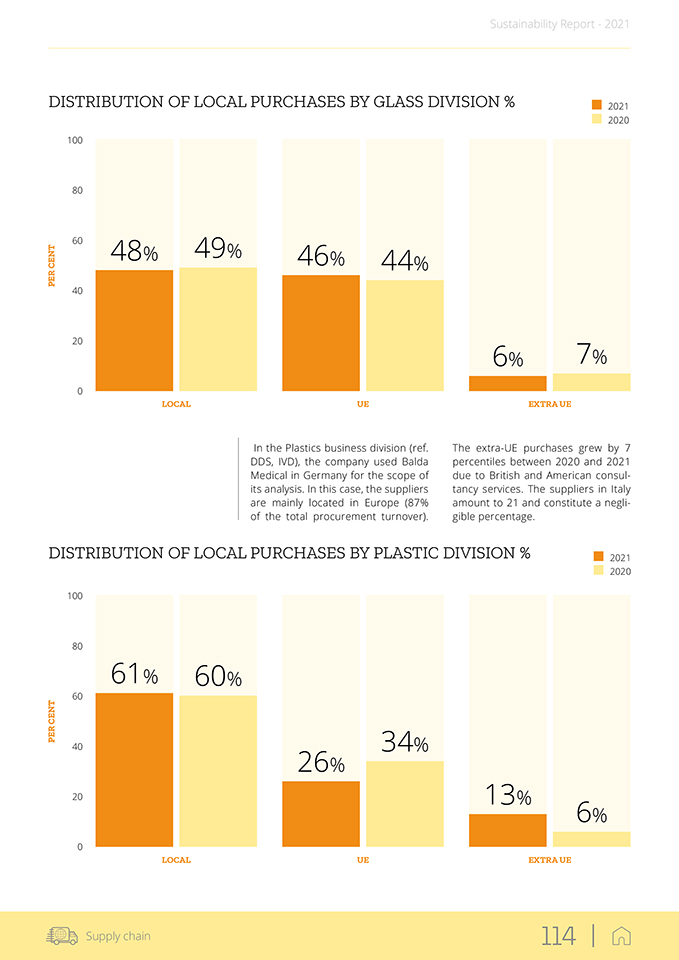

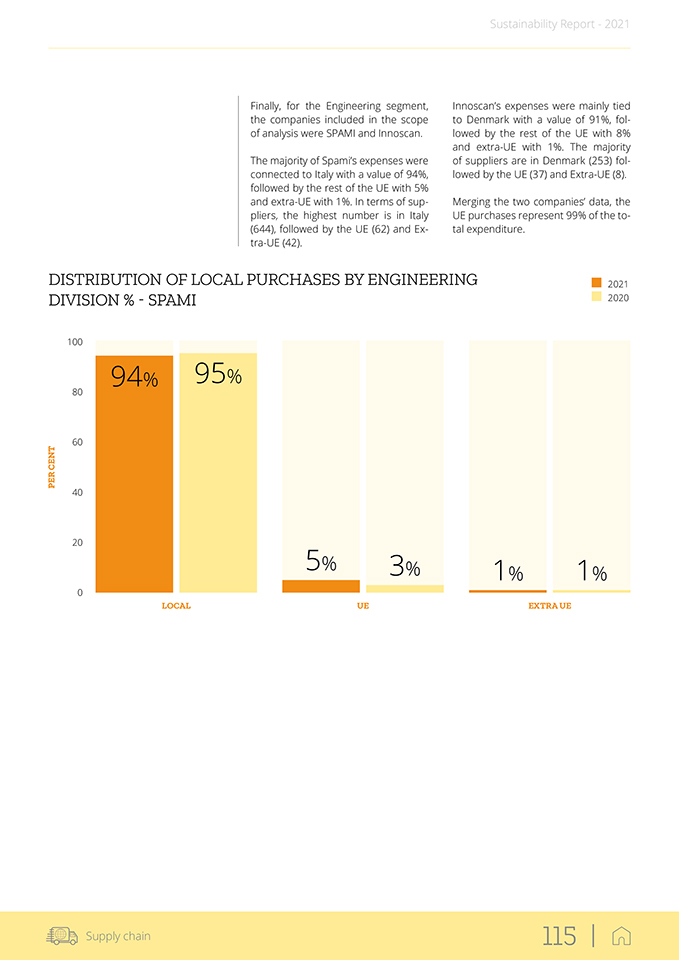

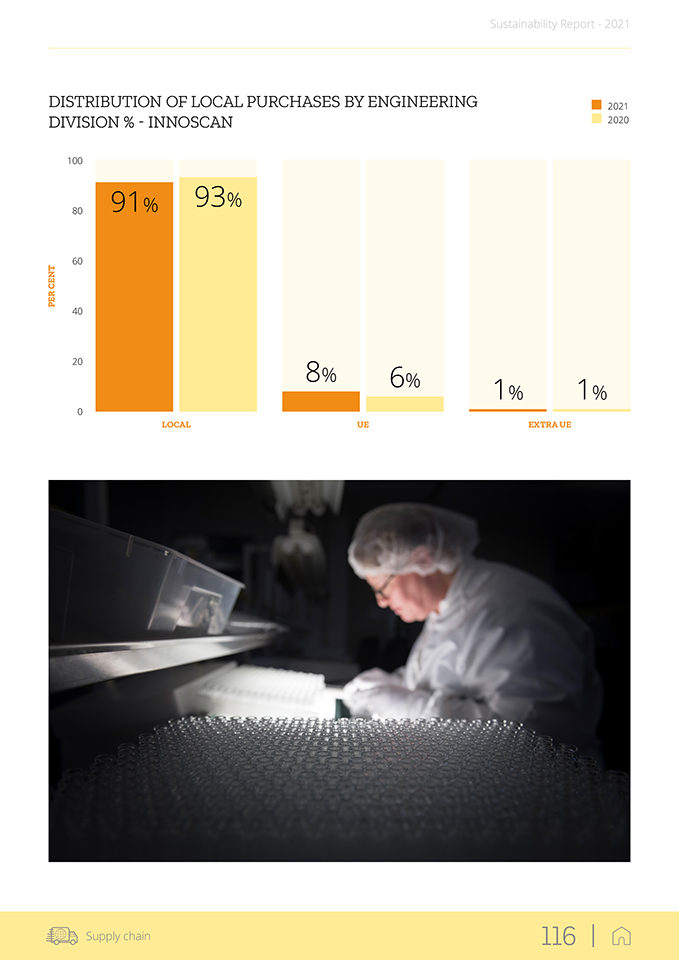

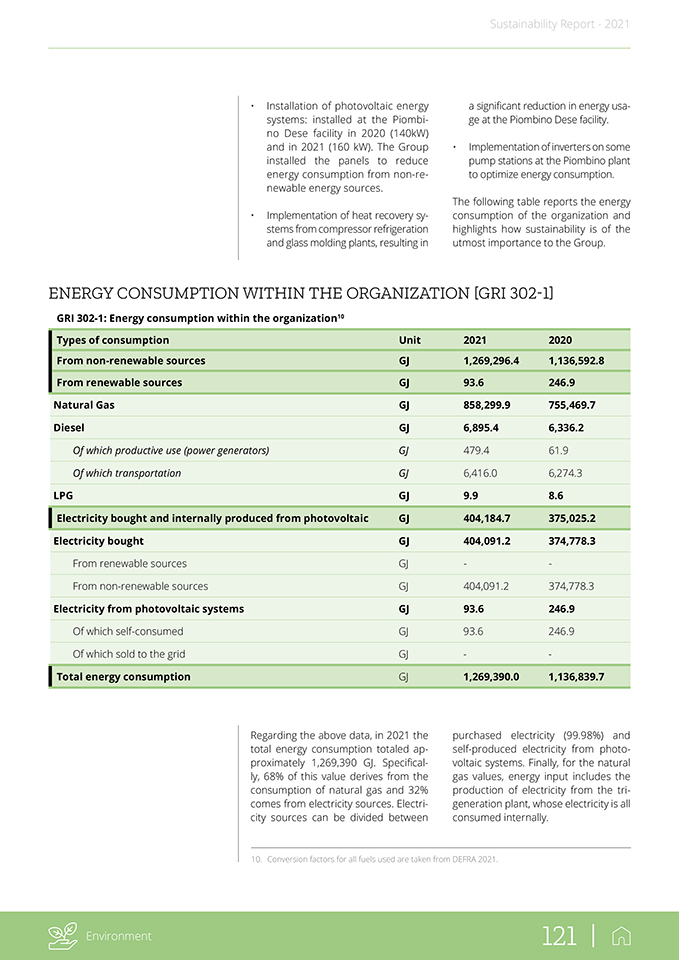

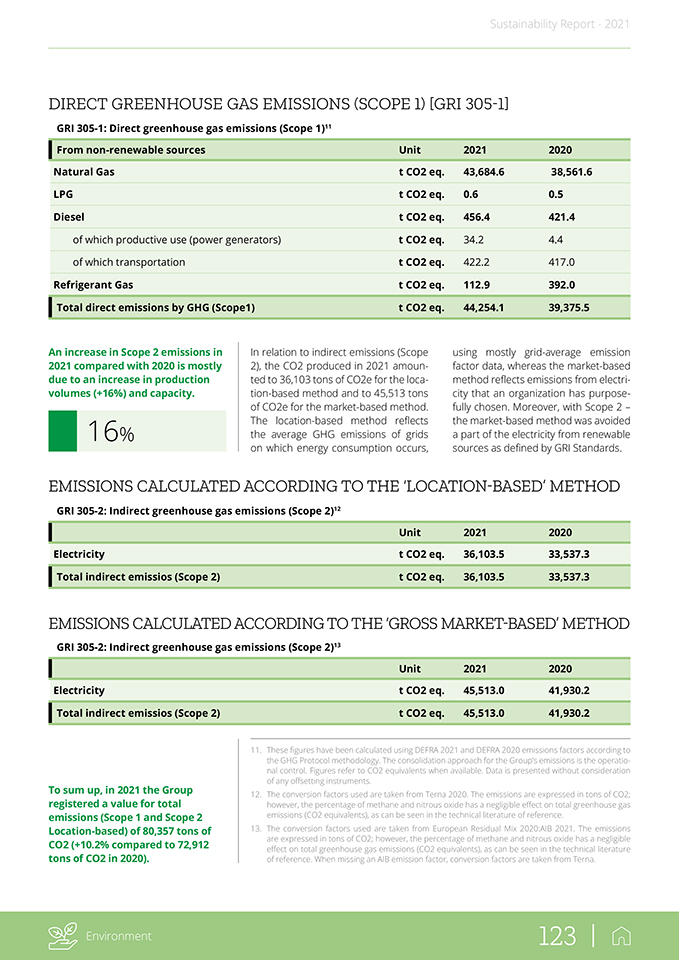

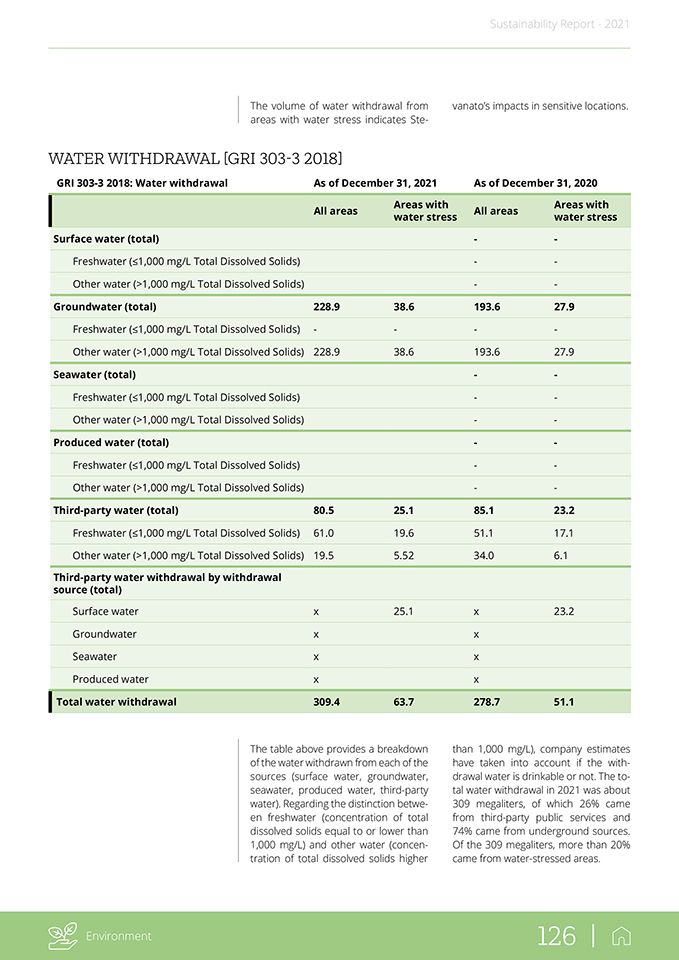

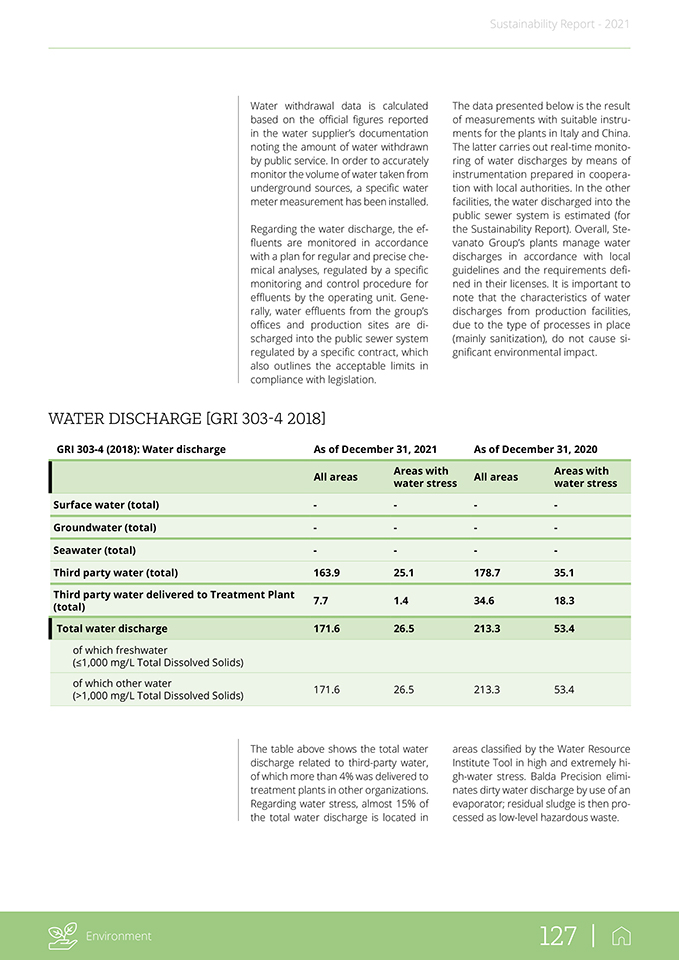

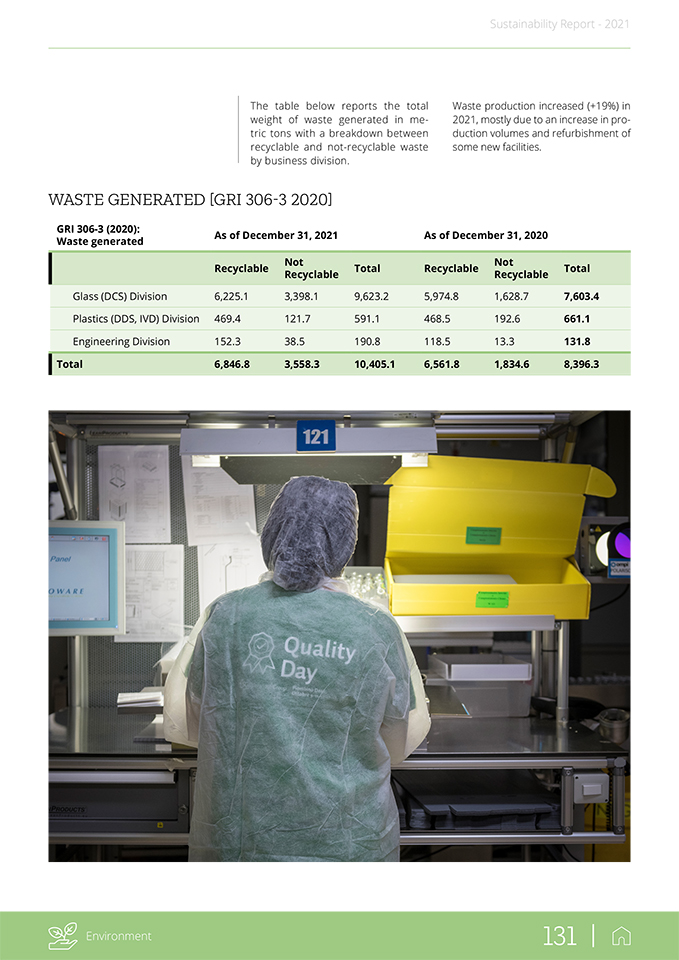

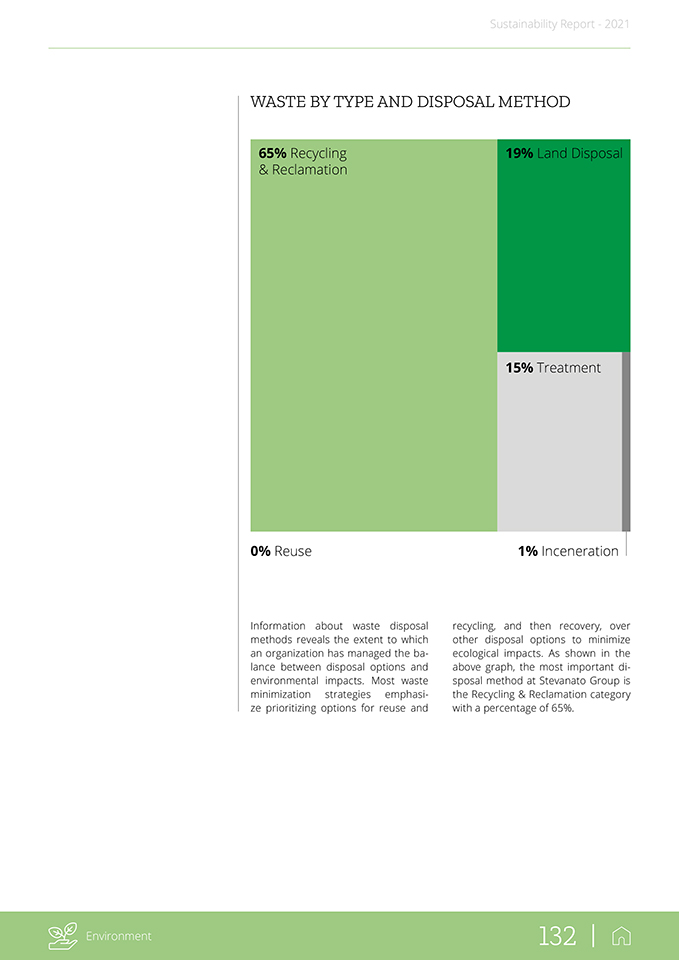

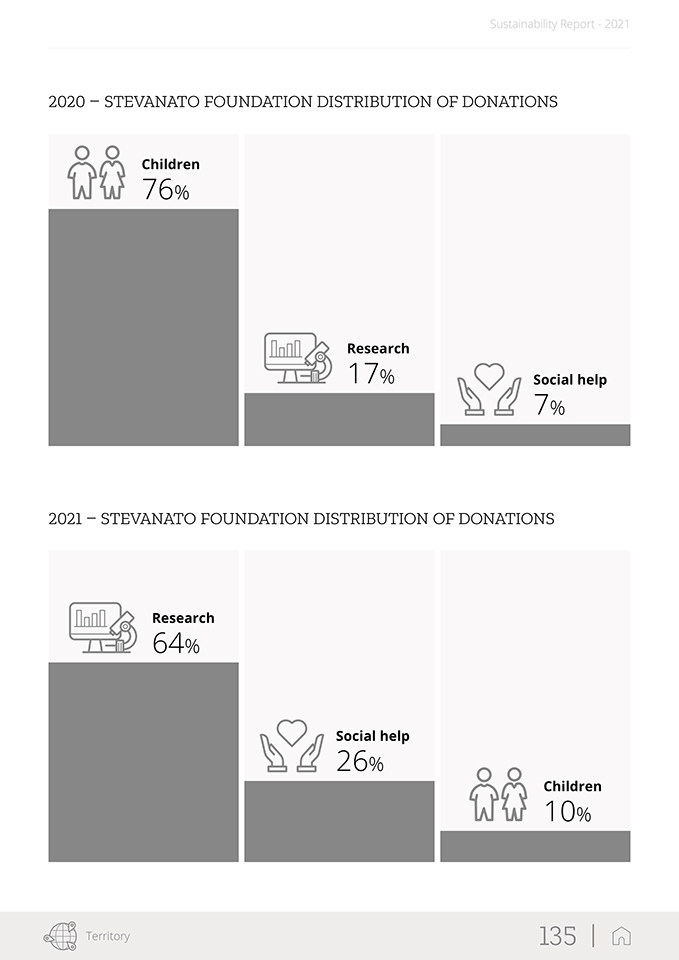

Direct economic value generated and distributed3 (€/000) [GRI 201-1] 2021 2020 (A) Total Economic value generated by Stevanato Group 865,391 670,252 (B) Economic value distributed by Stevanato Group 675,906 535,874 Operating costs – Remuneration to suppliers 424,043 313,208 Remuneration to personnel 211,635 194,484 Remuneration to lenders 8,637 9,815 Remuneration of the public administration 31,404 17,682 Donations 188 686 (A-B) Economic value retained by Stevanato Group 189,485 134,378 Amortization & Depreciation 55,440 53,893 Loss on receivable 946 215 Provisions and reserves (1,169) 1,673 Net Profit 134,269 78,598 In 2021, the economic value distributed by Stevanato Group resulted in a total amount of more than 675 million €. The difference between value created and distributed is the economic value retained by Stevanato Group, which goes towards further developing Group business, and is equal to more than 189 million €. In 2021, Stevanato Group directly generated over 865 million € in economic value (+29% in respect to 670 million € in 2020), of which 98% is attributed to busi- ness activity revenue and the remaining 2% is divided in other income, net financial income, income from participation and exchange rate differences. ECONOMIC VALUE DISTRIBUTED TO STAKEHOLDERS’ CATEGORIES IN PERCENTAGE IN 2021 Total economic value distributed by the Group 675,906 million € 62,74% Suppliers 31,31% Personnel 4,65% Public Administration 1,28% Lenders 0,03% Donations 3. Over the course of 2021, shareholders’ remuneration was covered by a withdrawal from the extraordinary reserve, thus not affecting the distribution of the economic value generated in 2021. Specifically, during 2021 dividends amounting to 11.2 million € were distributed to shareholders through the use of the extraordinary reserve.