Exhibit 99.3

SUSTAINABILITY REPORT 2022 SG Stevanto Group

Exhibit 99.3

SUSTAINABILITY REPORT 2022 SG Stevanto Group

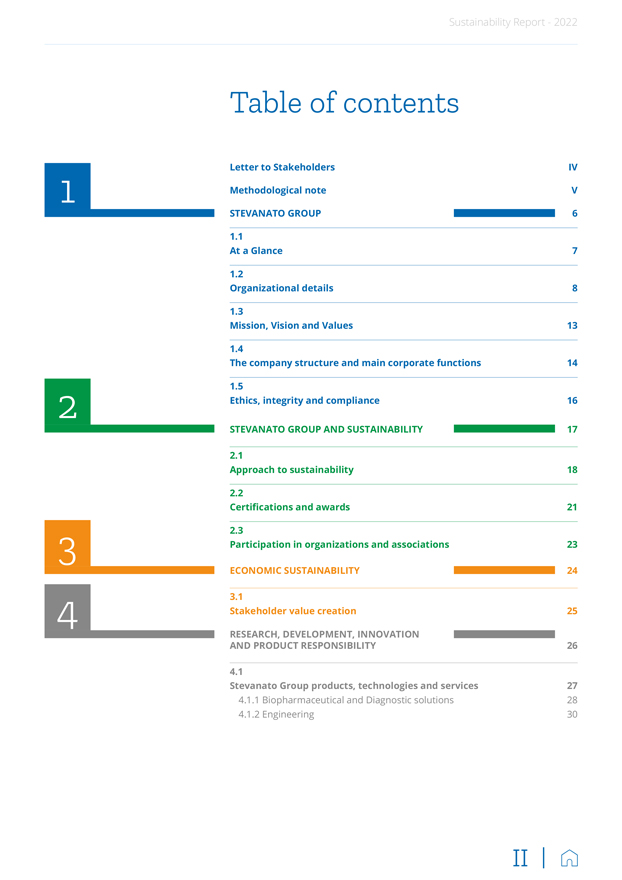

Sustainability Report - 2022 Table of contents Letter to Stakeholders IV Methodological note V 1 STEVANATO GROUP 6 1.1 At a Glance 7 1.2 Organizational details 8 1.3 Mission, Vision and Values 13 1.4 The company structure and main corporate functions 14 1.5 Ethics, integrity and compliance 16 2 STEVANATO GROUP AND SUSTAINABILITY 17 2.1 Approach to sustainability 18 2.2 Certifications and awards 21 2.3 Participation in organizations and associations 23 3 ECONOMIC SUSTAINABILITY 24 3.1 Stakeholder value creation 25 4 RESEARCH, DEVELOPMENT, INNOVATION AND PRODUCT RESPONSIBILITY 26 4.1 Stevanato Group products, technologies and services 27 4.1.1 Biopharmaceutical and Diagnostic solutions 28 4.1.2 Engineering 30 II

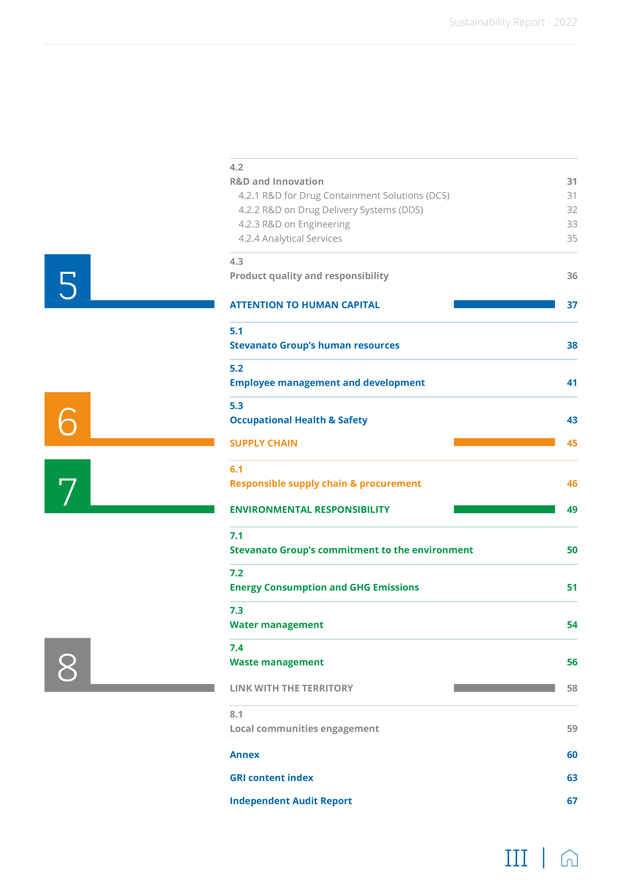

Sustainability Report - 2022 4.2 R&D and Innovation 31 4.2.1 R&D for Drug Containment Solutions (DCS) 31 4.2.2 R&D on Drug Delivery Systems (DDS) 32 4.2.3 R&D on Engineering 33 4.2.4 Analytical Services 35 ]4.3 Product quality and responsibility 36 5 ATTENTION TO HUMAN CAPITAL 37 5.1 Stevanato Group’s human resources 38 5.2 Employee management and development 41 5.3 Occupational Health & Safety 43 6 SUPPLY CHAIN 45 6.1 Responsible supply chain & procurement 46 7 ENVIRONMENTAL RESPONSIBILITY 49 7.1 Stevanato Group’s commitment to the environment 50 7.2 Energy Consumption and GHG Emissions 51 7.3 Water management 54 7.4 Waste management 56 8 LINK WITH THE TERRITORY 58 8.1 Local communities engagement 59 Annex 60 GRI content index 63 Independent Audit Report 67 III

Sustainability Report - 2022 Letter to Stakeholders Giovanni Stevanato had a dream and a vision. He wanted to create world-class glass manufacturing activities in Piombino Dese and set a standard of excellence. For over 70 years, we have been devoted to providing integrated solutions for the pharmaceutical and healthcare industry by constantly investing and acquiring skills in new technologies. A rich, international heritage has helped us become a global leader in drug containment, delivery, and diagnostic solutions. Our Vision is to create a reliable eco-system to empower our partners and enhance their ability to produce safe, easy-to-use and affordable treatments to improve patients’ lives. With this in mind, we invest in our business, our people, innovative solutions and scientific advancement, which we consider crucial to creating long-lasting value. In 2022, while facing global economic uncertainty and the war in Ukraine, we overcame inflation and supply chain constraints confronting most other companies by implementing diverse efficiency initiatives at all levels of the organization. In particular, we made progress in the expansion activities in Fishers (USA), Piombino Dese and Latina (Italy), and Zhangjiagang (China). We continued to seek growth in our mix of high-value solutions and fueled innovation by investing in R&D and partnering with other leading organizations. We also reviewed Stevanato’s organizational structure in an effort to provide better support to our international customers and continued to build a culture of internal control of our processes, which is required by our status as a public company, as well as strengthening our set of policies and procedures. Stevanato Group and its customers operate in a complex world. As a trusted partner, we help Biopharma and Diagnostics companies turn problems into solutions, managing complexity to deliver value for our clients, partners and the scientific community while keeping the customer, patient and stakeholders at the center of what we do. We strive to support our stakeholders while making a positive impact for the benefit of all. To this end, we regularly assess Environmental, Social and Governance impacts because we believe the ability to respond to such trends and risks may impact the long-term success of our company and society. Indeed, our goal is to pursue a regenerative business innovation journey while asserting our position as an interdependent and responsible member of the community in line with the United Nations’ Sustainable Development Goals. For our Group, sustainability is one of the primary means to tackling such complexity and we are committed to embedding it in our strategic plan, policies and practices. To safeguard the environment, we aim to reduce the impact of our processes and products starting with decarbonization and improvements in waste management. That same level of care applies to our people and is embodied by Stevanato’s Values and Guiding Principles and a workplace culture that fosters a culture that values both Health & Safety and Diversity, Equity & Inclusion. Finally, with reference to the Governance area, we aim to establish and maintain a sustainable corporate model through a dedicated governance structure and we are committed to regularly measure and report our progress on impacts using the GRI Standards criteria as a framework for transparency and accountability. In 2022, we were awarded a Bronze Medal by EcoVadis, an achievement that reflects the successful implementation of our sustainability strategy. The recognition acknowledges our ranking among the top 25% of companies in the “Manufacture of glass and glass products industry” and the top 34% of total companies rated by the platform. With the publication of Stevanato’s second Sustainability Report, our goal is to continue growing and supporting customers throughout our regenerative business innovation while making a positive impact everywhere we work and do business. We believe both our challenge and opportunity is to benefit from our know-how, resources, and enthusiasm to turn every project into an achievement while fostering health, wellbeing, and positive impacts for society and the planet. In close partnership with our stakeholders, we invest in sustainability today for a better tomorrow. Franco Stevanato Executive Chairman Stevanato Group S.p.A. Via Molinella 17, 35017 Piombino Dese · Padova · Italy Franco Moro Chief Executive Officer & Chief Operating Officer Stevanato Group S.p.A. Via Molinella 17, 35017 Piombino Dese · Padova · Italy IV

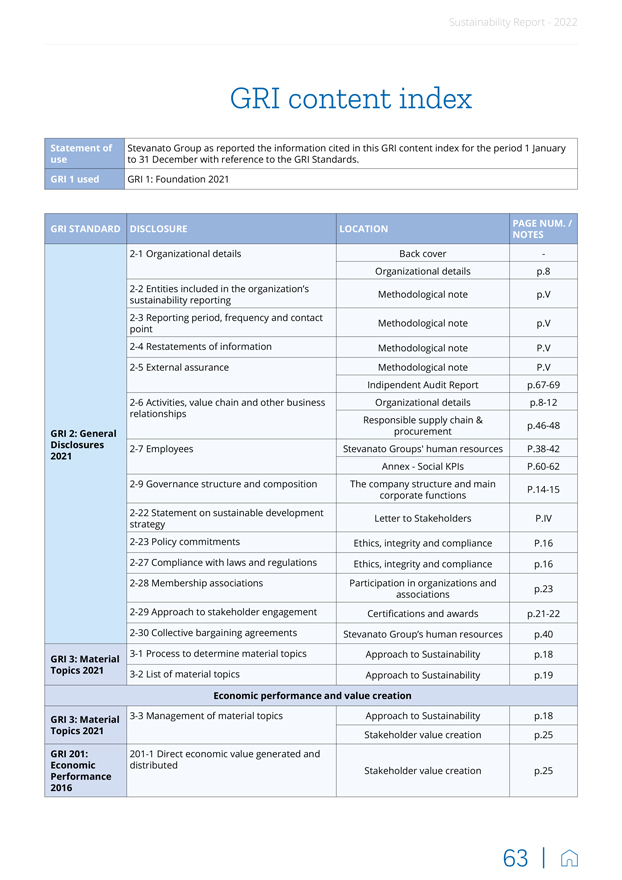

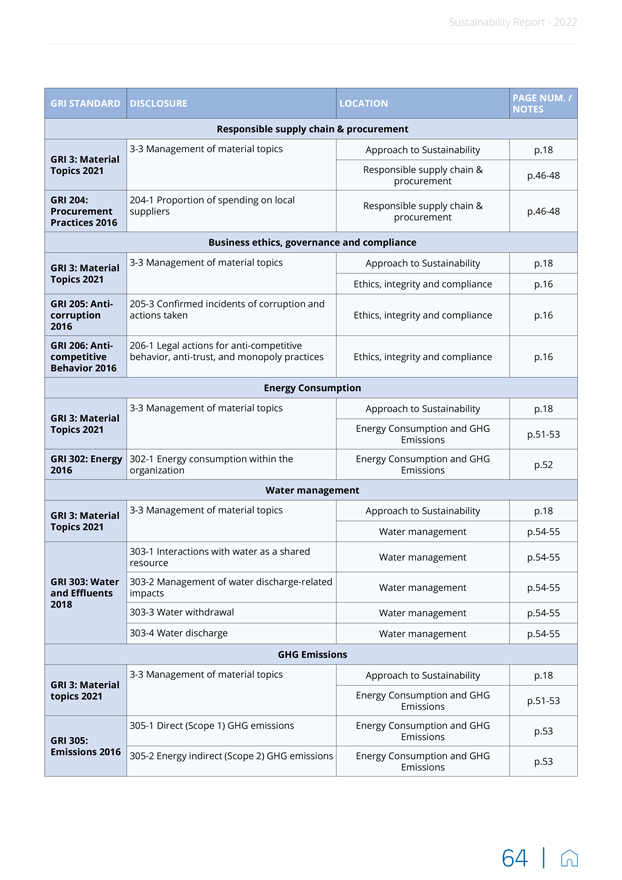

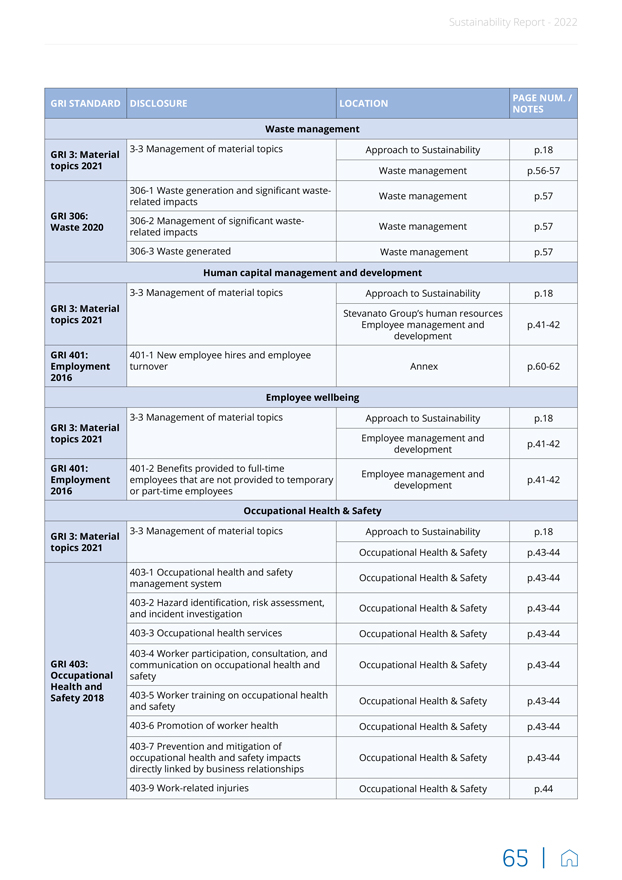

Sustainability Report - 2022 Methodological note Sustainability Report clearly outlines Stevanato Group’s environmental, social and economic achievements in a transparent and structured manner for the 2022 financial year (January 1-December 31) aligned with the company’s financial reporting, and shows the commitment and initiatives undertaken by the Group towards its goal of sustainable development. The annual reporting cycle provides internal and external stakeholders with a representation of Stevanato Group’s business performance, results and impact in relation to the main sustainability topics relating to the 2022 financial year. This document represents the Sustainability Report of the companies belonging to Stevanato Group and its subsidiaries (hereinafter also referred to as “the company,” “Stevanato,” the “Stevanato Group,” or “the Group”). The list of entities included in the sustainability reporting is aligned with the 2022 Annual 20F Filing1. The Sustainability Report includes data about the Parent Company Stevanato Group S.p.A. and its subsidiaries, which are directly or indirectly consolidated on a line-by-line basis. Note that some Group companies, which are not operational, have not been included in the EHS data due to limitation of scope (see relevant footnotes). Stevanato Group has reported sustainability information with reference to the GRI Standards 2021. For more details on GRI Standards, please see the table “GRI Content Index” in the appendix. The contents of the Sustainability Report were selected based on the results of a materiality analysis carried out in 2020 and updated in 2022 following GRI 3: Material Topics 2021 guidelines. The analysis took place in 2022 and confirmed the original list of material topics for the Group and its stakeholders as published in this document and described in Chapter 2. Information on quality criteria and the reporting scope were defined following the GRI principles and encompassed positive and negative impacts, comparability, accuracy, timeliness, clarity and verifiability. Specifically, the information included in this report was taken both from the Group’s IT system and from the sustainability reporting package. In order to properly manage the reporting process, a Sustainability Reporting Procedure was set up in 2021 and updated in 2022 in line with the GRI Standards 2021, which illustrates how to prepare the Group’s Sustainability Report including timing, tools, roles and responsibilities of the functions and individuals. To ensure responsiveness and proper application of the procedure, the reporting process was extensively discussed and agreed upon by the working group. The information presented in this report refers to 2022 and includes a comparison with the previous year. Any restatements of information made from previous reporting periods are appropriately indicated, when necessary, throughout the report. The information collected and reported is based on measurable data. To provide an accurate overview of the Group’s performance and help ensure data reliability, the use of estimates has been limited as much as possible. If they are provided, they have been made using the best methods available and are properly identified. The report presents both positive and negative aspects equally with a comment on the results when appropriate. This report was approved by the Board of Directors of Stevanato Group S.p.A. on April 5, 2023, and published in June. The process for seeking external assurance involved a preliminary evaluation based on different providers and relative core competencies and resulted in the selection and approval of Deloitte & Touche S.p.A. as external auditor. Stevanato Group commissioned the external auditor to provide a limited assurance report on select statements and figures in the Sustainability Report. The external assurance report (“limited assurance engagement” in accordance with the criteria indicated by the ISAE 3000 Revised Standard) is attached at the end of this document and contains a description of what has been assured and on what basis, including the assurance standard used, the level of assurance obtained, any limitation of the assurance process, and the relationships between the organization and the assurance provider. For further information and suggestions regarding Stevanato Group’s Sustainability Report, please contact: sustainability@stevanatogroup.com. 1 The scope of consolidation as of December 31, 2022, is essentially unchanged compared to December 31, 2021. On December 31, 2022, the extraordinary shareholders’ meetings held at Innoscan A/S and SVM Automatik A/S approved the merger of the non-surviving company, Innoscan A/S, into the surviving company, SVM Automatik A/S. The transaction is effective for accounting purposes as of January 1, 2022 V

Stevanato Group 1

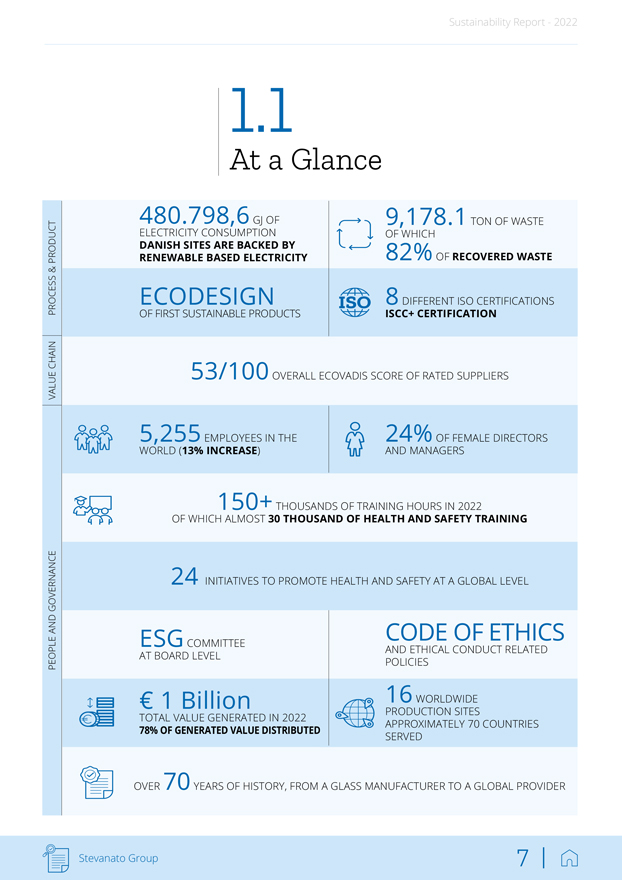

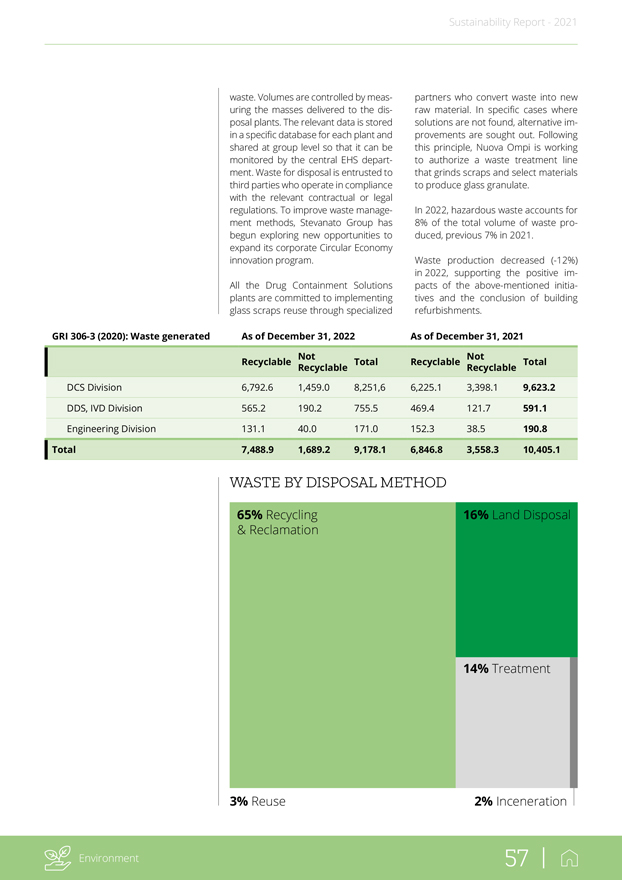

Sustainability Report - 2022 1.1 At a Glance PEOPLE AND GOVERNANCE VALUE CHAIN PROCESS & PRODUCT 480.798,6 GJ OF ELECTRICITY CONSUMPTION DANISH SITES ARE BACKED BY RENEWABLE BASED ELECTRICITY ECODESIGN OF FIRST SUSTAINABLE PRODUCTS 9,178.1 TON OF WASTE OF WHICH 82% OF RECOVERED WASTE 8 DIFFERENT ISO CERTIFICATIONS ISCC+ CERTIFICATION 53/100 OVERALL ECOVADIS SCORE OF RATED SUPPLIERS 5,255 EMPLOYEES IN THE WORLD (13% INCREASE) 24% OF FEMALE DIRECTORS AND MANAGERS 150+ THOUSANDS OF TRAINING HOURS IN 2022 OF WHICH ALMOST 30 THOUSAND OF HEALTH AND SAFETY TRAINING 24 INITIATIVES TO PROMOTE HEALTH AND SAFETY AT A GLOBAL LEVEL ESG COMMITTEE AT BOARD LEVEL CODE OF ETHICS AND ETHICAL CONDUCT RELATED POLICIES € 1 Billion TOTAL VALUE GENERATED IN 2022 78% OF GENERATED VALUE DISTRIBUTED 16 WORLDWIDE PRODUCTION SITES APPROXIMATELY 70 COUNTRIES SERVED OVER 70 YEARS OF HISTORY, FROM A GLASS MANUFACTURER TO A GLOBAL PROVIDER Stevanato Group 7

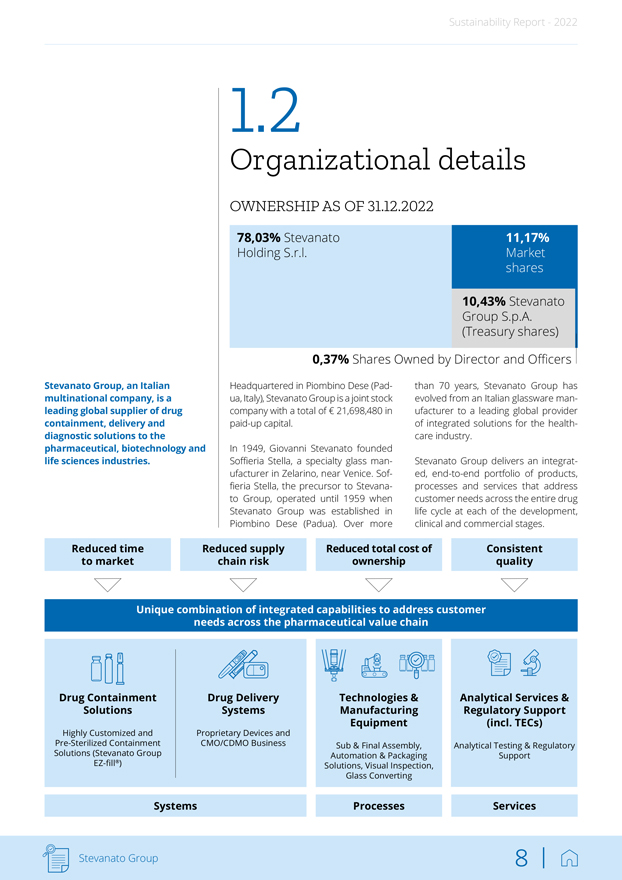

Sustainability Report - 2022 Stevanato Group, an Italian multinational company, is a leading global supplier of drug containment, delivery and diagnostic solutions to the pharmaceutical, biotechnology and life sciences industries. 1.2 Organizational details OWNERSHIP AS OF 31.12.2022 78,03% Stevanato Holding S.r.l. 11,17% Market shares 10,43% Stevanato Group S.p.A. (Treasury shares) 0,37% Shares Owned by Director and Officers Headquartered in Piombino Dese (Padua, Italy), Stevanato Group is a joint stock company with a total of 21,698,480 in paid-up capital. In 1949, Giovanni Stevanato founded Soffieria Stella, a specialty glass manufacturer in Zelarino, near Venice. Soffieria Stella, the precursor to Stevanato Group, operated until 1959 when Stevanato Group was established in Piombino Dese (Padua). Over more than 70 years, Stevanato Group has evolved from an Italian glassware manufacturer to a leading global provider of integrated solutions for the healthcare industry. Stevanato Group delivers an integrated, end-to-end portfolio of products, processes and services that address customer needs across the entire drug life cycle at each of the development, clinical and commercial stages. Reduced time to market Reduced supply chain risk Reduced total cost of ownership Consistent quality Unique combination of integrated capabilities to address customer needs across the pharmaceutical value chain Drug Containment Solutions Highly Customized and Pre-Sterilized Containment Solutions (Stevanato Group EZ-fill) Drug Delivery Systems Proprietary Devices and CMO/CDMO Business Technologies & Manufacturing Equipment Sub & Final Assembly, Automation & Packaging Solutions, Visual Inspection, Glass Converting Analytical Services & Regulatory Support (incl. TECs) Analytical Testing & Regulatory Support Systems Processes Services Stevanato Group 8

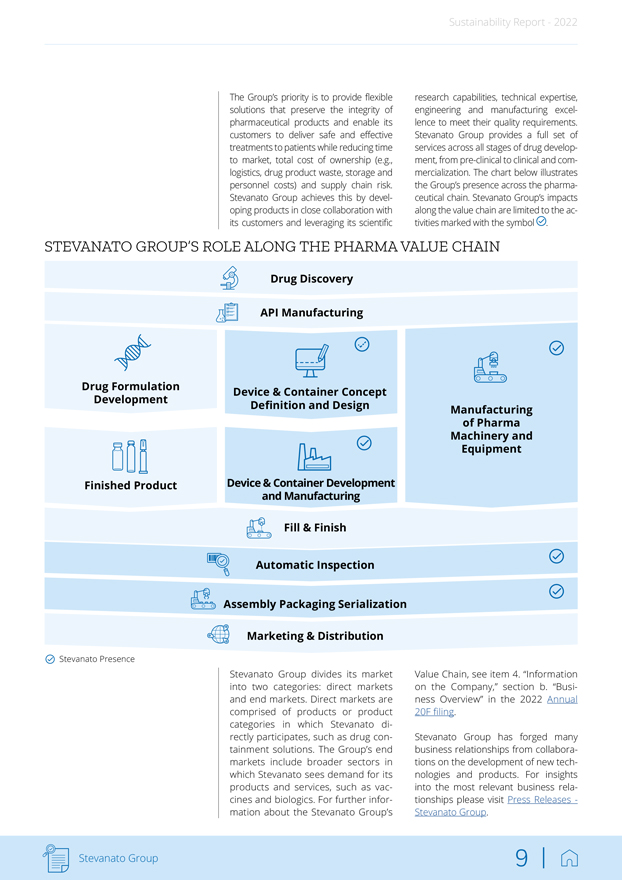

Sustainability Report – 2022 The Group’s priority is to provide flexible solutions that preserve the integrity of pharmaceutical products and enable its customers to deliver safe and effective treatments to patients while reducing time to market, total cost of ownership (e.g., logistics, drug product waste, storage and personnel costs) and supply chain risk. Stevanato Group achieves this by developing products in close collaboration with its customers and leveraging its scientific research capabilities, technical expertise, engineering and manufacturing excellence to meet their quality requirements. Stevanato Group provides a full set of services across all stages of drug development, from pre-clinical to clinical and commercialization. The chart below illustrates the Group’s presence across the pharmaceutical chain. Stevanato Group’s impacts along the value chain are limited to the activities marked with the symbol . STEVANATO GROUP’S ROLE ALONG THE PHARMA VALUE CHAIN Drug Discovery API Manufacturing Drug Formulation Development Device & Container Concept Definition and Design Finished Product Device & Container Development and Manufacturing Manufacturing of Pharma Machinery and Equipment Fill & Finish Automatic Inspection Assembly Packaging Serialization Marketing & Distribution Stevanato Presence Stevanato Group divides its market into two categories: direct markets and end markets. Direct markets are comprised of products or product categories in which Stevanato directly participates, such as drug containment solutions. The Group’s end markets include broader sectors in which Stevanato sees demand for its products and services, such as vaccines and biologics. For further information about the Stevanato Group’s Value Chain, see item 4. “Information on the Company,” section b. “Business Overview” in the 2022 Annual 20F filing. Stevanato Group has forged many business relationships from collaborations on the development of new technologies and products. For insights into the most relevant business relationships please visit Press Releases - Stevanato Group. Stevanato Group 9

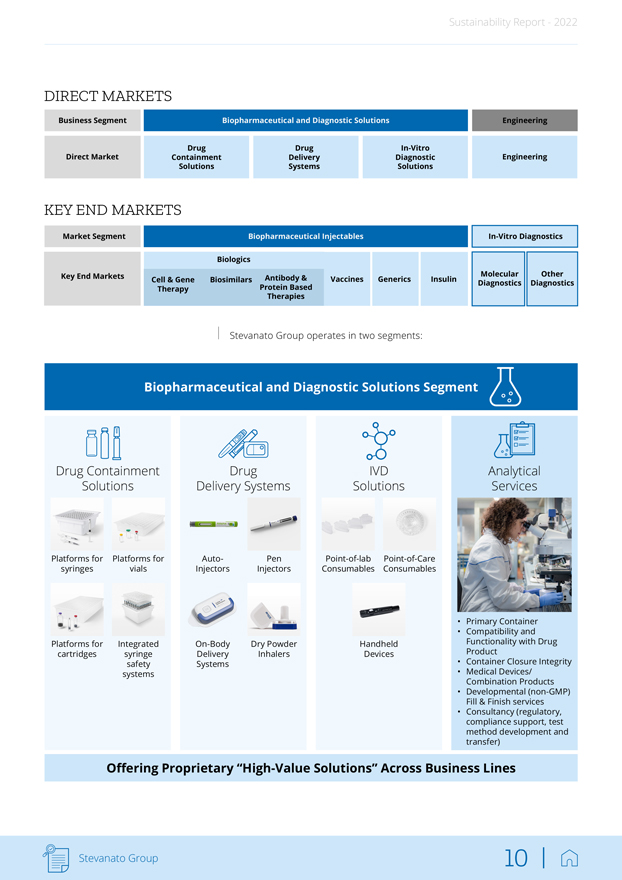

Sustainability Report - 2022 DIRECT MARKETS Business Segment Biopharmaceutical and Diagnostic Solutions Engineering Direct Market Drug Containment Solutions Drug Delivery Systems In-Vitro Diagnostic Solutions Engineering KEY END MARKETS Market Segment Biopharmaceutical Injectables In-Vitro Diagnostics Key End Markets Biologics Cell & Gene Therapy Biosimilars Antibody & Protein Based Therapies Vaccines Generics Insulin Molecular Diagnostics Other Diagnostics Stevanato Group operates in two segments: Biopharmaceutical and Diagnostic Solutions Segment Drug Containment Solutions Drug Delivery Systems IVD Solutions Analytical Services Platforms for syringes Platforms for vials Auto-Injectors Pen Injectors Point-of-lab Consumables Point-of-Care Consumables Platforms for cartridges Integrated syringe safety systems On-Body Delivery Systems Dry Powder Inhalers Handheld Devices • Primary Container • Compatibility and Functionality with Drug Product • Container Closure Integrity • Medical Devices/ Combination Products • Developmental (non-GMP) Fill & Finish services • Consultancy (regulatory, compliance support, test method development and transfer) Offering Proprietary “High-Value Solutions” Across Business Lines Stevanato Group 10

Sustainability Report – 2022 Engineering Segment Assembly Visual Inspection Packaging & Serialization Glass Converting After-Sales • Sub-assembly and final assembly for drug delivery devices • Highly automated modular platforms • Semi-automatic and automatic inspection machines • Diversified portfolio • Artificial Intelligence Platform for Automated Visual Inspection • Single point of contact for packaging processes • Range of formats, reproducible settings • Traceability with serialization • Fully automated high-speed precision glass converting lines • Extensive dimensional and cosmetic inline controls • Advanced after-sales services • Global service based on technical expertise and interactive tools Highly automated and advanced equipment for both in-house use and sale to customers The Group is a truly global company spread across different countries and continents: Stevanato Group 11

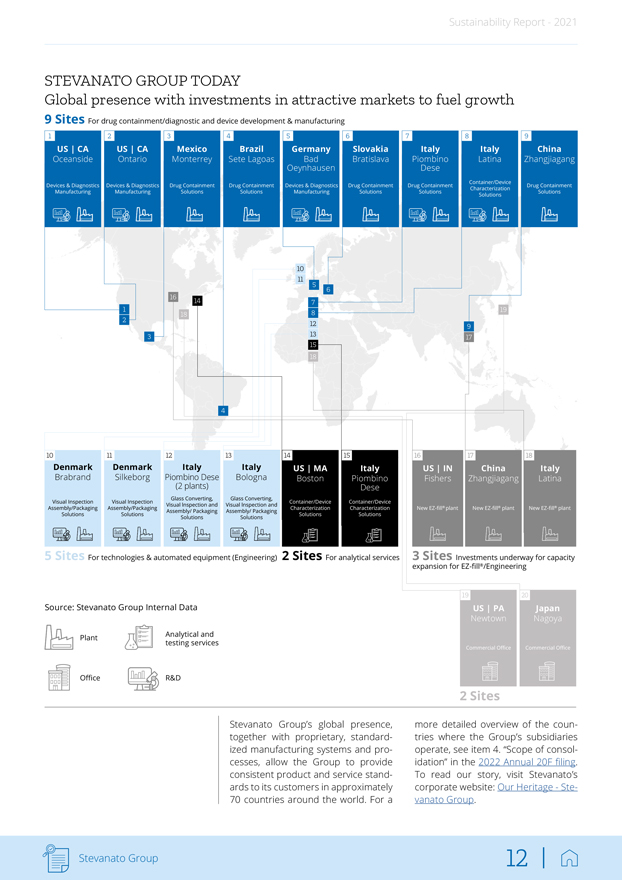

Sustainability Report - 2021 STEVANATO GROUP TODAY Global presence with investments in attractive markets to fuel growth 9 Sites For drug containment/diagnostic and device development & manufacturing 1 US | CA Oceanside Devices & Diagnostics Manufacturing 2 US | CA Ontario Devices & Diagnostics Manufacturing 3 Mexico Monterrey Drug Containment Solutions 4 Brazil Sete Lagoas Drug Containment Solutions 5 Germany Bad Oeynhausen Devices & Diagnostics Manufacturing 6 Slovakia Bratislava Drug Containment Solutions 7 Italy Piombino Dese Drug Containment Solutions 8 Italy Latina Container/Device Characterization Solutions 9 China Zhangjiagang Drug Containment Solutions 10 Denmark Brabrand Visual Inspection Assembly/Packaging Solutions 11 Denmark Silkeborg Visual Inspection Assembly/Packaging Solutions 12 Italy Piombino Dese (2 plants) Glass Converting, Visual lnspection and Assembly/ Packaging Solutions 13 Italy Bologna Glass Converting, Visual lnspection and Assembly/ Packaging Solutions 14 US | MA Boston Container/Device Characterization Solutions 15 Italy Piombino Dese Container/Device Characterization Solutions 16 US | IN Fishers New EZ-fill® plant 17 China Zhangjiagang New EZ-fill® plant 18 Italy Latina New EZ-fill® plant 5 Sites For technologies & automated equipment (Engineering) 2 Sites For analytical services 3 Sites Investments underway for capacity expansion for EZ-fill®/Engineering Source: Stevanato Group Internal Data Plant Analytical and testing services Office R&D 19 US | PA Newtown Commercial Office 20 apan Nagoya Commercial Office 2 Sites Stevanato Group’s global presence, together with proprietary, standardized manufacturing systems and processes, allow the Group to provide consistent product and service standards to its customers in approximately 70 countries around the world. For a more detailed overview of the countries where the Group’s subsidiaries operate, see item 4. “Scope of consolidation” in the 2022 Annual 20F filing. To read our story, visit Stevanato’s corporate website: Our Heritage - Ste-vanato Group. Stevanato Group 12

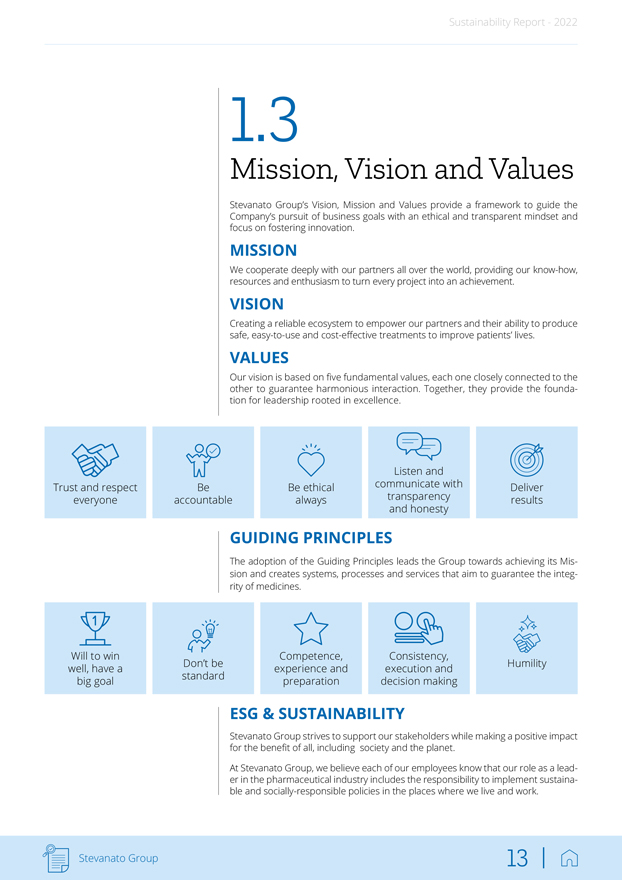

Sustainability Report – 2022 1.3 Mission, Vision and Values Stevanato Group’s Vision, Mission and Values provide a framework to guide the Company’s pursuit of business goals with an ethical and transparent mindset and focus on fostering innovation.MISSION We cooperate deeply with our partners all over the world, providing our know-how, resources and enthusiasm to turn every project into an achievement. VISION Creating a reliable ecosystem to empower our partners and their ability to produce safe, easy-to-use and cost-effective treatments to improve patients’ lives. VALUES Our vision is based on five fundamental values, each one closely connected to the other to guarantee harmonious interaction. Together, they provide the foundation for leadership rooted in excellence. Trust and respect everyone Be accountable Be ethical always Listen and communicate with transparency and honesty Deliver results GUIDING PRINCIPLES The adoption of the Guiding Principles leads the Group towards achieving its Mission and creates systems, processes and services that aim to guarantee the integrity of medicines. Will to win well, have a big goal Don’t be standard Competence, experience and preparation Consistency, execution and decision making Humility ESG & SUSTAINABILITY Stevanato Group strives to support our stakeholders while making a positive impact for the benefit of all, including society and the planet. At Stevanato Group, we believe each of our employees know that our role as a leader in the pharmaceutical industry includes the responsibility to implement sustainable and socially-responsible policies in the places where we live and work. Stevanato Group 13

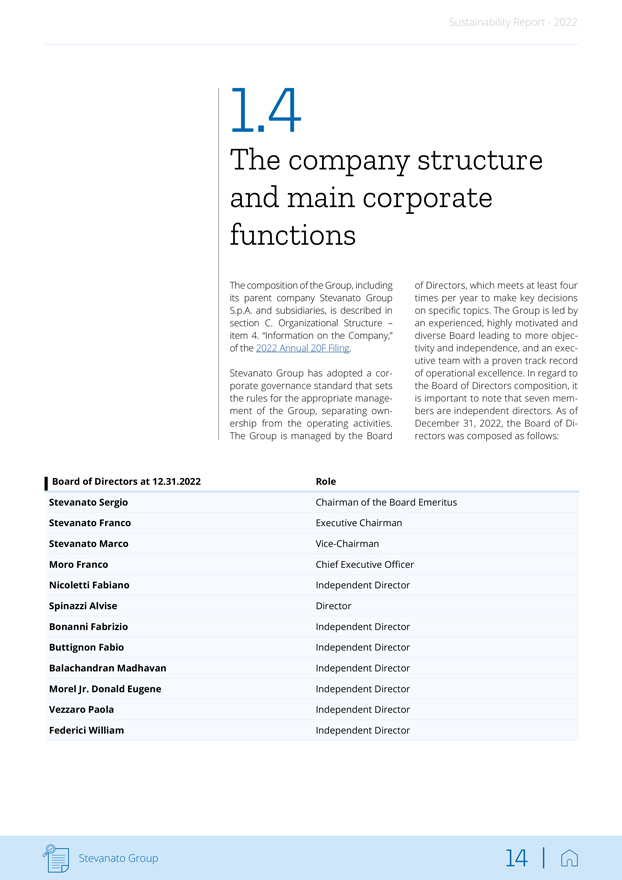

Sustainability Report - 2022 1.4 The company structure and main corporate functions The composition of the Group, including its parent company Stevanato Group S.p.A. and subsidiaries, is described in section C. Organizational Structure – item 4. “Information on the Company,” of the 2022 Annual 20F Filing. Stevanato Group has adopted a corporate governance standard that sets the rules for the appropriate management of the Group, separating ownership from the operating activities. The Group is managed by the Board of Directors, which meets at least four times per year to make key decisions on specific topics. The Group is led by an experienced, highly motivated and diverse Board leading to more objectivity and independence, and an executive team with a proven track record of operational excellence. In regard to the Board of Directors composition, it is important to note that seven members are independent directors. As of December 31, 2022, the Board of Directors was composed as follows: Board of Directors at 12.31.2022 Role Stevanato Sergio Chairman of the Board Emeritus Stevanato Franco Executive Chairman Stevanato Marco Vice-Chairman Moro Franco Chief Executive Officer Nicoletti Fabiano Independent Director Spinazzi Alvise Director Bonanni Fabrizio Independent Director Buttignon Fabio Independent Director Balachandran Madhavan Independent Director Morel Jr. Donald Eugene Independent Director Vezzaro Paola Independent Director Federici William Independent Director Stevanato Group 14

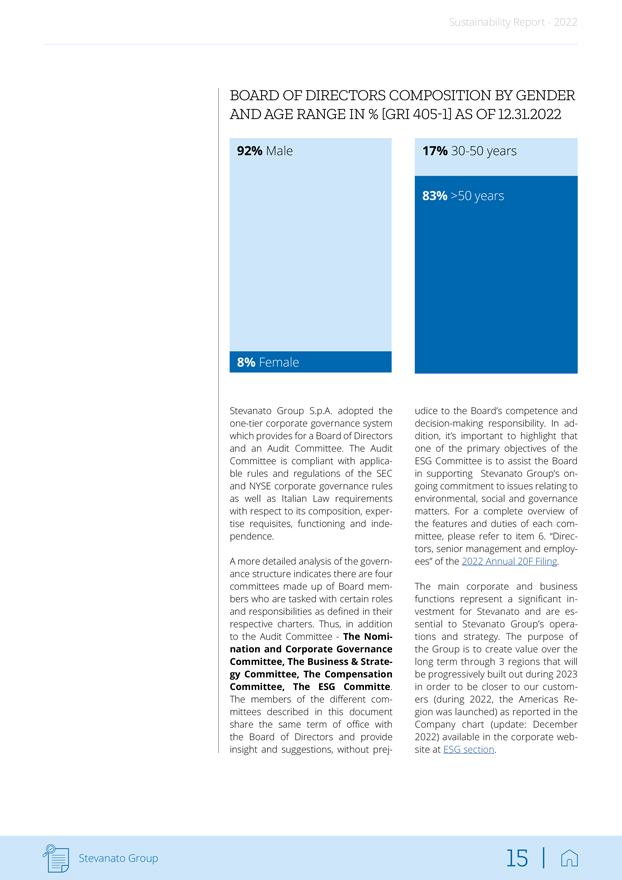

Sustainability Report - 2022 BOARD OF DIRECTORS COMPOSITION BY GENDER AND AGE RANGE IN % [GRI 405-1] AS OF 12.31.2022 92% Male 17% 30-50 years 83% >50 years 8% Female Stevanato Group S.p.A. adopted the one-tier corporate governance system which provides for a Board of Directors and an Audit Committee. The Audit Committee is compliant with applicable rules and regulations of the SEC and NYSE corporate governance rules as well as Italian Law requirements with respect to its composition, expertise requisites, functioning and independence. A more detailed analysis of the governance structure indicates there are four committees made up of Board members who are tasked with certain roles and responsibilities as defined in their respective charters. Thus, in addition to the Audit Committee - The Nomination and Corporate Governance Committee, The Business & Strategy Committee, The Compensation Committee, The ESG Committe. The members of the different committees described in this document share the same term of office with the Board of Directors and provide insight and suggestions, without prejudice to the Board’s competence and decision-making responsibility. In addition, it’s important to highlight that one of the primary objectives of the ESG Committee is to assist the Board in supporting Stevanato Group’s ongoing commitment to issues relating to environmental, social and governance matters. For a complete overview of the features and duties of each committee, please refer to item 6. “Directors, senior management and employees” of the 2022 Annual 20F Filing. The main corporate and business functions represent a significant investment for Stevanato and are essential to Stevanato Group’s operations and strategy. The purpose of the Group is to create value over the long term through 3 regions that will be progressively built out during 2023 in order to be closer to our customers (during 2022, the Americas Region was launched) as reported in the Company chart (update: December 2022) available in the corporate website at ESG section. Stevanato Group 15

Sustainability Report – 2022 1.5 Ethics, integrity and compliance An essential factor for business success and an indispensable asset to the Company’s reputation and to maintain a sustainable transparent corporate model is the adoption of high ethical conduct standards and a culture of ethical behaviors and integrity. The Group is committed to embedding sustainability values into its policies and practices. The main commitments for responsible business conduct at Stevanato Group are defined in the documents, corporate policy and statements described below. Please note that all documents disclosed have been approved by the Board of Directors of Stevanato Group and are available on the corporate website. The Code of Ethics defines the guidelines and criteria of conduct for all recipients and aims to ensure compliance with regulations in force to prevent improper acts or behavior and to help protect the legitimate interests of customers, employees, shareholders, business and financial partners, communities and diverse stakeholder groups. The Code of Ethics has been disseminated in all of Stevanato Group’s companies. The provisions contained in the Code of Ethics have been reported via specific internal policies and procedures that ensure compliance with the principles and guidelines of the Code of Ethics. For further details on the Code of Ethics and other policies, please refer to the links below: Code of Ethics Anti-Bribery and Anti-Corruption policy Related Party Transactions Policy Anti-Discrimination Policy The Code of Ethics and the Anti-Discrimination Policy cover internationally recognized human rights that are disclosed directly throughout the documentation. In 2022, the Related Party Transaction Policy was revised by the Audit Committee. Stevanato Group acts in compliance with intellectual, industrial and commercial property rights, as well as with international laws and regulations, in order to protect its rights and interests. In 2022, no significant instances of non-compliance with laws and regulations were registered. In April 2021, Stevanato Group adopted a whistleblowing procedure to manage the reporting of any violations and irregularities concerning the Code of Ethics related to Italian Legal Entities. Employees can report any violations or suspected violations to the Company through a dedicated email address: csr-compliance@stevanatogroup.com. The information transmitted is promptly checked and, once the Report has been verified, the case is submitted to the competent corporate department for the application of any disciplinary sanctions or for the activation of contractual termination mechanisms. This whistleblowing procedure is designed to ensure the confidentiality of the person reporting the issue and the information received, as well as its validity. As of December 31, 2022, no grievances had been sent to the relevant function inbox and, during 2022, no cases of incidents of corruption or human rights violations were reported in the Group. In accordance with Italian law, The Italian subsidiaries of Stevanato Group have an Organizational, Management and Control model as per Legislative Decree no. 231/01, which was revised in 2022 and approved by the Board of Directors. Consequently, the parent company has set up a Supervisory Body pursuant to the aforementioned Legislative Decree responsible for monitoring compliance, operating and updating the Model. A communication channel has been established at the e-mail address odv. stevanatogroup@stevanatogroup.com, which only members of the Supervisory Board may access to receive reports of any violations or suspected violations of the Model from internal and external subjects. For its foreign companies, the Group is currently working to strengthen management systems to ensure compliance with local laws in consideration of the provisions of the Model of Organization, Management and Control 231. With reference to business relationships, Stevanato Group has established a Code of Conduct that is shared with its suppliers. For more information, see section 6.1 Supply Chain. As testimony to the Group’s ongoing commitment to ethical conduct and integrity, there were no reports and/or complaints received about non-compliance with laws or regulations, or legal action taken regarding anti-competitive behavior, anti-trust or monopoly violations either in or out of court in 2022. For an overview on Stevanato Group risk management, see item 3. “Risk Factor” of the 2022 Annual 20F Filing. Stevanato Group 16

Stevanato Group and Sustainability SG Stevanato Group 2

Sustainability Report – 2022 2.1 Approach to Sustainability Stevanato Group aims to ensure its long-term success based on its ability to respond to trends and risks related to Environmental, Social and Governance (ESG) matters that make up the complex context in which the Group operates. Sustainability is a primary means to improve such opportunity and risk management, while resulting in higher efficiency, cutting-edge innovation and strategic decisions on technologies, products, processes and value chain definition. Stevanato Group pursues a sustainable development journey in line with its materiality analysis and the United Nations’ Sustainable Development Goals. In particular, the Company seeks to create a regenerative business innovation model while remaining an interdependent and responsible member of the community. To safeguard the environment, Ste-vanato Group aims to reduce the environmental impact of its processes and products starting with decarbonization and improvements in waste management. Indeed, Stevanato has initiated life cycle percepective analyses on select products while advancing eco-design solutions that reduce, reuse, replace and recycle. As part of its corporate sustainability innovation measures, Stevanato Group launched a sustainable version of secondary packaging for syringes focusing on biopolymers and recycled plastic in addition to packaging and process improvements to reduce related emissions and other sustainable practices, and ensuring the chain of custody along the value chain with ISCC+ certification. Stevanato Group’s Values and Guiding Principles are the cornerstone of our corporate work ethic and promote harmonious human interactions. To foster a fair and inclusive workplace culture, Stevanato Group also uphold the tenets of Health & Safety and Diversity, Equity & Inclusion, to the highest standards. In regards to governance, Stevanato Group aims to establish and maintain a sustainable corporate model through a dedicated governance structure and regularly measures and reports on its progress and impacts using the GRI Standards as a framework for transparency and accountability. Through a materiality assessment conducted in 2020, the Group identified the primary ESG issues relevant to the organization and its stakeholders. For the FY 2022, the Group updated its materiality analysis, aligning it with the GRI Standards 2021 in force for reports published as of January 1, 2023. The main steps followed by the Group in 2020 are reported in the chart below. Identification of Relevant Topics Analysis of the context in which the Group operates, regarding the reference sector Definition of a list of relevant topics Internal Assessment Assessment by Group management and internal stakeholders External Assessment Assessment by external stakeholder Stevanato Group Materiality Matrix Sustainability 18

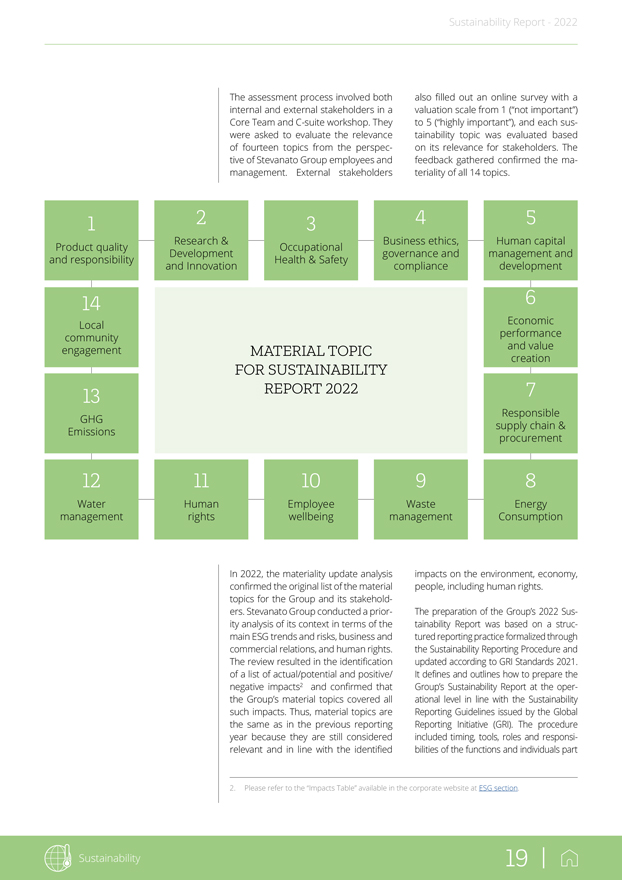

Sustainability Report – 2022 The assessment process involved both internal and external stakeholders in a Core Team and C-suite workshop. They were asked to evaluate the relevance of fourteen topics from the perspective of Stevanato Group employees and management. External stakeholders also filled out an online survey with a valuation scale from 1 (“not important”) to 5 (“highly important”), and each sustainability topic was evaluated based on its relevance for stakeholders. The feedback gathered confirmed the materiality of all 14 topics. 1 Product quality and responsibility 2 Research & Development and Innovation 3 Occupational Health & Safety 4 Business ethics, governance and compliance 5 Human capital management and development 6 Economic performance and value creation 7 Responsible supply chain & procurement 8 Energy Consumption 9 Waste management 10 Employee wellbeing 11 Human rights 12 Water management 13 GHG Emissions 14 Local community engagement MATERIAL TOPIC FOR SUSTAINABILITY REPORT 2022 In 2022, the materiality update analysis confirmed the original list of the material topics for the Group and its stakeholders. Stevanato Group conducted a priority analysis of its context in terms of the main ESG trends and risks, business and commercial relations, and human rights. The review resulted in the identification of a list of actual/potential and positive/ negative impacts2 and confirmed that the Group’s material topics covered all such impacts. Thus, material topics are the same as in the previous reporting year because they are still considered relevant and in line with the identified impacts on the environment, economy, people, including human rights. The preparation of the Group’s 2022 Sustainability Report was based on a structured reporting practice formalized through the Sustainability Reporting Procedure and updated according to GRI Standards 2021. It defines and outlines how to prepare the Group’s Sustainability Report at the operational level in line with the Sustainability Reporting Guidelines issued by the Global Reporting Initiative (GRI). The procedure included timing, tools, roles and responsibilities of the functions and individuals part 2. Please refer to the “Impacts Table” available in the corporate website at ESG section. Sustainability 19

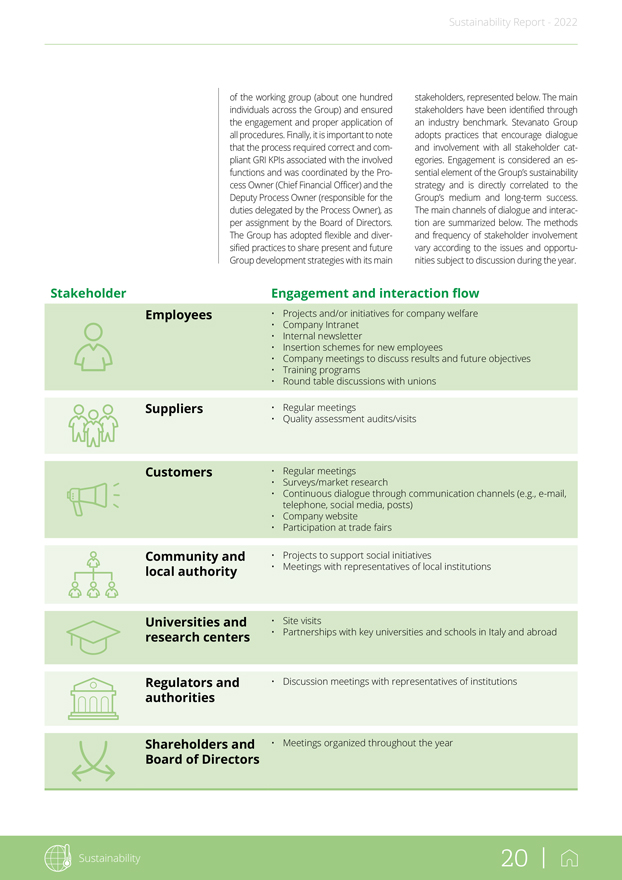

Sustainability Report – 2022 of the working group (about one hundred individuals across the Group) and ensured the engagement and proper application of all procedures. Finally, it is important to note that the process required correct and compliant GRI KPIs associated with the involved functions and was coordinated by the Process Owner (Chief Financial Officer) and the Deputy Process Owner (responsible for the duties delegated by the Process Owner), as per assignment by the Board of Directors. The Group has adopted flexible and diversified practices to share present and future Group development strategies with its main stakeholders, represented below. The main stakeholders have been identified through an industry benchmark. Stevanato Group adopts practices that encourage dialogue and involvement with all stakeholder categories. Engagement is considered an essential element of the Group’s sustainability strategy and is directly correlated to the Group’s medium and long-term success. The main channels of dialogue and interaction are summarized below. The methods and frequency of stakeholder involvement vary according to the issues and opportunities subject to discussion during the year. Stakeholder Engagement and interaction flow Employees Projects and/or initiatives for company welfare Company Intranet Internal newsletter Insertion schemes for new employees Company meetings to discuss results and future objectives Training programs Round table discussions with unions Suppliers Regular meetings Quality assessment audits/visits Customers Regular meetings Surveys/market research Continuous dialogue through communication channels (e.g., e-mail, telephone, social media, posts) Company website Participation at trade fairs Community and local authority Projects to support social initiatives Meetings with representatives of local institutions Universities and research centers Site visits Partnerships with key universities and schools in Italy and abroad Regulators and authorities Discussion meetings with representatives of institutions Shareholders and Board of Directors Meetings organized throughout the year Sustainability 20

Sustainability Report – 2022 2.2 Certifications and awards Certification Description Company (countries) ISO 15378 Primary packaging material for medicine products—particular requirements for the application of ISO 9001:2015 with reference to Good Manufacturing Practice (GMP) Nuova Ompi (IT-PD) Nuova Ompi (IT-LT) Medical Glass (SK) Ompi North America (MX) Ompi of China (CN) Ompi do Brasil (BR) Balda (DE) ISO 13485 Medical devices—Quality management systems Nuova Ompi (IT-PD) Balda (DE) Balda (US) SG Lab (IT-PD) US Tech (US) ISO 9001 Quality management systems Nuova Ompi ( IT-PD) Nuova Ompi (IT-LT) Medical Glass (SK) Ompi North America (MX) Ompi of China (CN) Ompi do Brasil (BR) Balda (DE) Balda (US) Spami (IT) SG Lab (IT-PD) US Tech (US) ISO 45001 Occupational Health and Safety Management System Nuova Ompi (IT-PD) Nuova Ompi (IT-LT) Medical Glass (SK) Ompi North America (MX) Ompi of China (CN) Ompi do Brasil (BR) Balda (DE) ISO 14001 Environmental management systems Nuova Ompi (IT-PD) Nuova Ompi (IT-LT) Medical Glass (SK) Ompi North America (MX) Ompi of China (CN) Ompi do Brasil (BR) Balda (DE) ISO 50001 Energy management systems Balda (DE) ISO 17665 Sterilization of health care products—Moist heat Nuova Ompi (IT-PD) ISCC+ International Sustainability and Carbon Certification Nuova Ompi (IT-PD) Balda (DE) ISO 17025 General requirements for the competence of testing and calibration laboratories SG Lab (IT-PD) Sustainability 21

Sustainability Report – 2022 BRONZE 2022 ecovadis Sustainability Rating 2021 PHARMA INNOVATION AWARDS PHARMA MANUFACTURING C_lab Contamination Lab Veneto One of the most important awards Stevanato Group received in 2022 was the Eco-Vadis Bronze Medal. The award acknowledges companies’ sustainable business practices in regards to the environment, labor and human rights, ethics and sustainable procurement. EcoVadis rated the Group’s performance in the top 25% of companies in the “Manufacture of glass and glass products industry” and the top 34% of companies overall. Sustainability 22

Sustainability Report – 2022 2.3 Participation in organizations and associations Stevanato Group cooperates with an extensive network of trade associations and organizations, facilitating the exchange of ideas, knowledge and different points of view DCAT ISPE® PDA® Parental Drug Association MassBio® Massachusetts Biotechnology Council ICG International Commission on Glass China Pharmaceutical Packaging Association Sustainability 23

Economic Sustainability 3

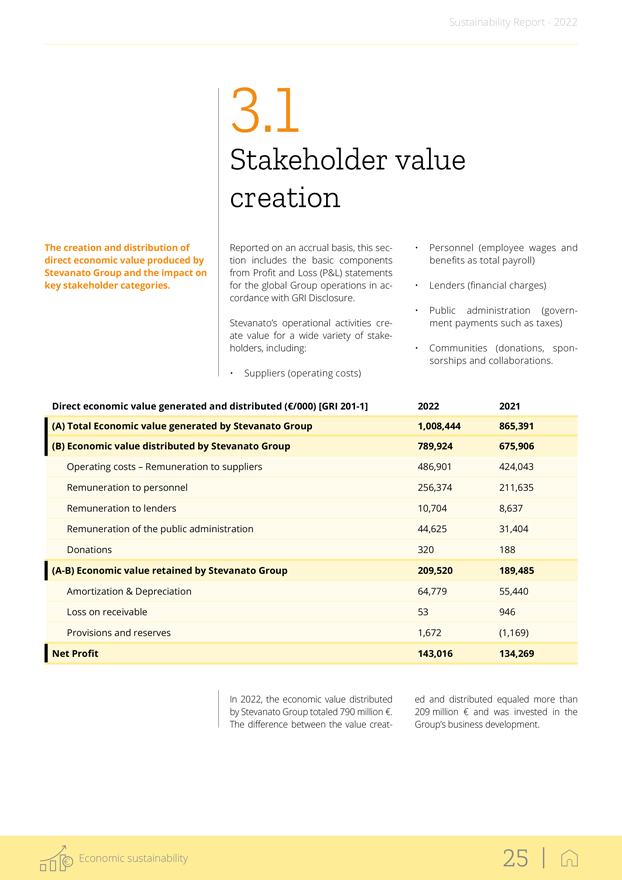

The creation and distribution of direct economic value produced by Stevanato Group and the impact on key stakeholder categories. 3.1 Stakeholder value creation Reported on an accrual basis, this section includes the basic components from Profit and Loss (P&L) statements for the global Group operations in accordance with GRI Disclosure. Stevanatos operational activities create value for a wide variety of stakeholders, including: " Suppliers (operating costs) " Personnel (employee wages and benefits as total payroll) " Lenders (financial charges) " Public administration (government payments such as taxes) " Communities (donations, sponsorships and collaborations. Direct economic value generated and distributed ( /000) [GRI 201-1] 2022 2021 (A) Total Economic value generated by Stevanato Group 1,008,444 865,391 (B) Economic value distributed by Stevanato Group 789,924 675,906 Operating costs Remuneration to suppliers 486,901 424,043 Remuneration to personnel 256,374 211,635 Remuneration to lenders 10,704 8,637 Remuneration of the public administration 44,625 31,404 Donations 320 188 (A-B) Economic value retained by Stevanato Group 209,520 189,485 Amortization & Depreciation 64,779 55,440 Loss on receivable 53 946 Provisions and reserves 1,672 (1,169) Net Profit 143,016 134,269 In 2022, the economic value distributed by Stevanato Group totaled 790 million . The difference between the value created and distributed equaled more than 209 million and was invested in the Groups business development.

4 Research, development, innovation and product responsibility

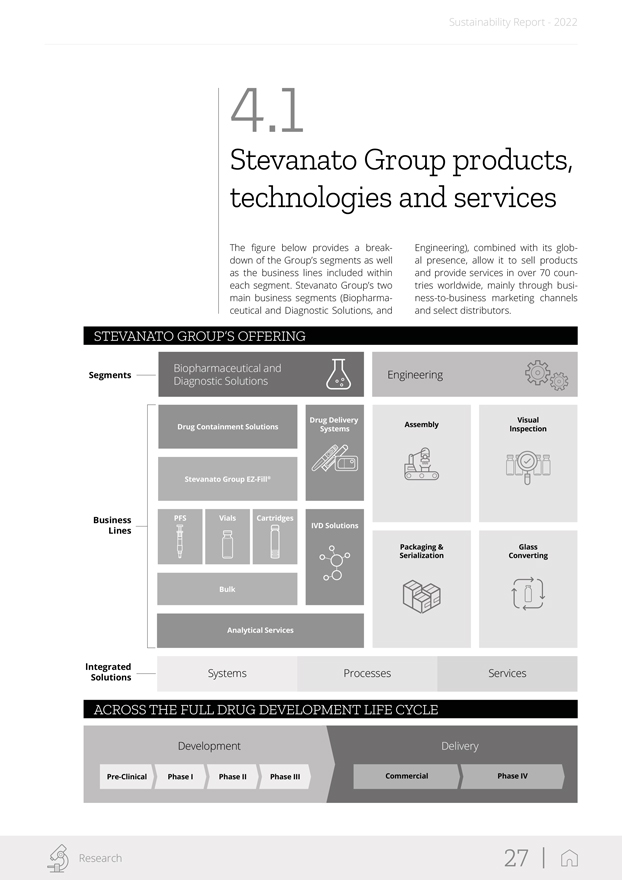

4.1 Stevanato Group products, technologies and services The figure below provides a breakdown of the Groups segments as well as the business lines included within each segment. Stevanato Groups two main business segments (Biopharma-ceutical and Diagnostic Solutions, and Engineering), combined with its global presence, allow it to sell products and provide services in over 70 countries worldwide, mainly through business-to-business marketing channels and select distributors. STEVANATO GROUPS OFFERING Segments Biopharmaceutical and Diagnostic Solutions Engineering Business Lines Drug Containment Solutions Stevanato Group EZ-Fill(R) PFS Vials Cartridges Bulk Analytical Services Drug Delivery Systems IVD Solutions Assembly Visual lnspection Packaging & Serialization Glass Converting lntegrated Solutions Systems Processes Services ACROSS THE FULL DRUG DEVELOPMENT LIFE CYCLE Development Delivery Pre-Clinical Phase I Phase II Phase III Commercial Phase IV

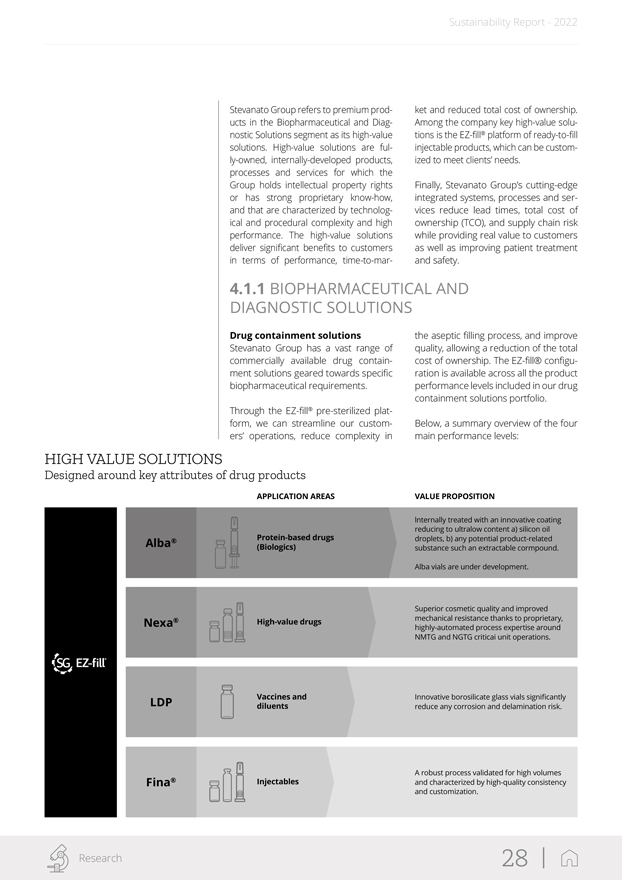

Stevanato Group refers to premium products in the Biopharmaceutical and Diagnostic Solutions segment as its high-value solutions. High-value solutions are fully-owned, internally-developed products, processes and services for which the Group holds intellectual property rights or has strong proprietary know-how, and that are characterized by technological and procedural complexity and high performance. The high-value solutions deliver significant benefits to customers in terms of performance, time-to-market and reduced total cost of ownership. Among the company key high-value solutions is the EZ-fill(R) platform of ready-to-fill injectable products, which can be customized to meet clients needs. Finally, Stevanato Groups cutting-edge integrated systems, processes and services reduce lead times, total cost of ownership (TCO), and supply chain risk while providing real value to customers as well as improving patient treatment and safety. 4.1.1 BIOPHARMACEUTICAL AND DIAGNOSTIC SOLUTIONS Drug containment solutions Stevanato Group has a vast range of commercially available drug containment solutions geared towards specific biopharmaceutical requirements. Through the EZ-fill(R) pre-sterilized platform, we can streamline our customers operations, reduce complexity in the aseptic filling process, and improve quality, allowing a reduction of the total cost of ownership. The EZ-fill(R) configuration is available across all the product performance levels included in our drug containment solutions portfolio. Below, a summary overview of the four main performance levels: HIGH VALUE SOLUTIONS Designed around key attributes of drug products SG EZ-fill APPLICATION AREAS VALUE PROPOSITION Alba(R) Protein-based drugs (Biologics) lnternally treated with an innovative coating reducing to ultralow content a) silicon oil droplets, b) any potential product-related substance such an extractable cormpound. Alba vials are under development. Nexa(R) High-value drugs Superior cosmetic quality and improved mechanical resistance thanks to proprietary, highly-automated process expertise around NMTG and NGTG criticai unit operations. LDP Vaccines and diluents Innovative borosilicate glass vials signicantly reduce any corrosion and delamination risk. Fina(R) Injectables A robust process validated for high volumes and characterized by high-quality consistency and customization.

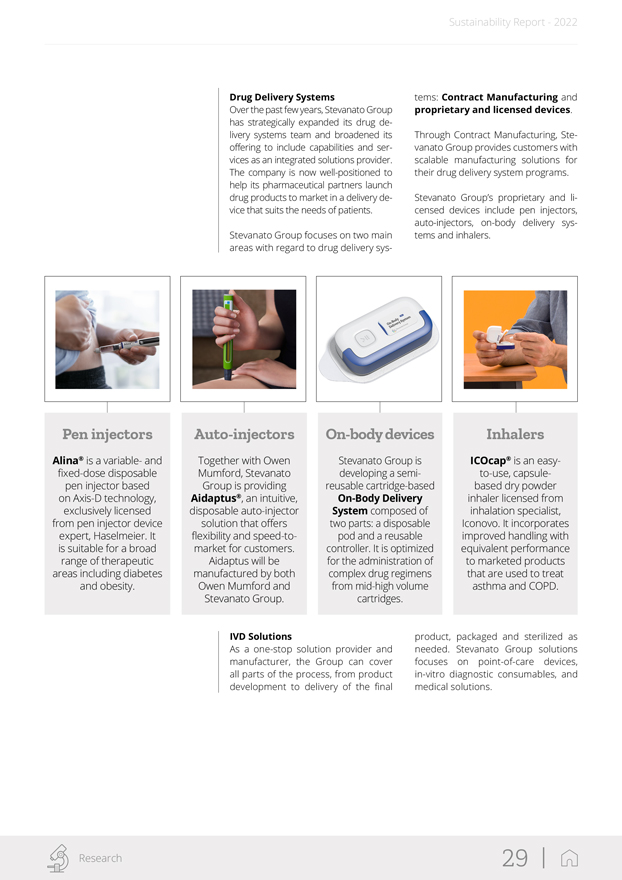

Drug Delivery Systems Over the past few years, Stevanato Group has strategically expanded its drug delivery systems team and broadened its offering to include capabilities and services as an integrated solutions provider. The company is now well-positioned to help its pharmaceutical partners launch drug products to market in a delivery device that suits the needs of patients. Stevanato Group focuses on two main areas with regard to drug delivery systems: Contract Manufacturing and proprietary and licensed devices. Through Contract Manufacturing, Stevanato Group provides customers with scalable manufacturing solutions for their drug delivery system programs. Stevanato Groups proprietary and licensed devices include pen injectors, auto-injectors, on-body delivery systems and inhalers. Pen injectors Alina(R) is a variable- and fixed-dose disposable pen injector based on Axis-D technology, exclusively licensed from pen injector device expert, Haselmeier. It is suitable for a broad range of therapeutic areas including diabetes and obesity. Auto-injectors Together with Owen Mumford, Stevanato Group is providing Aidaptus(R), an intuitive, disposable auto-injector solution that offers flexibility and speed-to-market for customers. Aidaptus will be manufactured by both Owen Mumford and Stevanato Group. On-body devices Stevanato Group is developing a semi-reusable cartridge-based On-Body Delivery System composed of two parts: a disposable pod and a reusable controller. It is optimized for the administration of complex drug regimens from mid-high volume cartridges. Inhalers ICOcap(R) is an easy-to-use, capsule-based dry powder inhaler licensed from inhalation specialist, Iconovo. It incorporates improved handling with equivalent performance to marketed products that are used to treat asthma and COPD. IVD Solutions As a one-stop solution provider and manufacturer, the Group can cover all parts of the process, from product development to delivery of the final product, packaged and sterilized as needed. Stevanato Group solutions focuses on point-of-care devices, in-vitro diagnostic consumables, and medical solutions.

Analytical services As a branch of Research and Development, our Technology Excellence Centers focus on investigating the physical-chemical properties of primary packaging materials and components and studying the interactions between drug containment solutions and drugs. Stevanato Group relies on a multi-disciplinary team of highly-skilled professionals including scientists, engineers, pharmaceutical chemists and biotechnologists. Their knowledge and experience cover a range of specialized areas including drug containment solutions and drug-delivery devices. 4.1.2 ENGINEERING Stevanato Group counts on a vast portfolio of technologies and manufacturing equipment to best serve its customers. First, the Group is specialized in glass converting, producing fully-automated, high-speed, precision glass tube converting lines through its brand, Spami. The Group can provide accurate processing of ampoules, vials, cartridges and syringes throughout the development process and rigorous product inspection via state-of-the-art camera control systems. Secondly, Stevanato Group provides flexible inspection solutions at any stage of the product journey, from lab development to high-volume production. The Group provides inspection solutions for ampoules, vials, cartridges, syringes or bottles filled with various drugs. The inspection machines can be divided into manual, semi-automatic and automatic equipment. Finally, Stevanato offers device assembly and packaging equipment, designing and manufacturing flexible stand-alone or turnkey integrated systems that address customers needs from the early stages up to commercialization. It delivers precision assembly of a wide variety of medical devices including pen injectors, auto-injectors, nasal sprays, inhalers, wearables, cartoning machines, packaging machinery and palletizing modules, and utilizes equipment compliant with serialization and tamper-evident requirements.

Stevanato Group believes that its greatest challenge and opportunity is to continue growing and supporting its customers through regenerative business innovation while making a positive impact that benefits all. The Group acts as a trusted partner for customers and develops mission-critical drug containment, delivery and diagnostic solutions. Drug Containment Solutions Developing solutions to maintain the stability, potency and purity of biopharma customers products Drug Delivery Systems Focusing on DDS patient-centricity, sustainability and digitalization Process Excellence & Digitalization Continuously innovating the Group manufacturing processes to deliver superior quality, reducing waste and risk of drug shortages 4.2 R&D and Innovation Investment in research and development is a fundamental component of Stevanato Groups growth and continued success. The company invested approximately 34.4 million in 2022 corresponding to 3.5% of revenue (in 2021, 29.6 million was invested, equal to 3.5% of revenue). The research and development team comprises about 140 highly-skilled and specialized employees operating in Italy, Germany and the United States. R&D also represents a dimension of Stevanato Groups vision, allowing it to evolve from a packaging component and automated equipment supplier to a leading provider of mission-critical drug containment, delivery and diagnostic solutions for the pharmaceutical, biotechnology and life sciences industries. The R&D department is divided into two divisions in line with Stevanato Groups business segments: Biopharmaceutical and Diagnostic Solutions, and Engineering. The two R&D divisions cooperate in perfect synergy in terms of maximizing value creation and accomplishing cross-functional projects. The mutual strategy of Stevanato Groups R&D department is based on three fundamental pillars that focus and align the R&D team with the Companys business growth. These three pillars are the guidelines of the Groups R&D divisions: each R&D project is designed to contribute and support one or more of these pillars. As far as R&D and Innovation products, Stevanato Group is committed to introduce sustainability concepts in its programs since the beginning of projects. Dedicated check lists for each single new product/project will be implemented and then monitored thus to be sure to keep sustainability high in the development of new products, independent on the area of development. For instance, such approach is applied at concept design stage, at materials selection stage or on how to extend the lifetime of the product or allow its reuse. 4.2.1 R&D FOR DRUG CONTAINMENT SOLUTIONS (DCS) Stevanatos DCS team is dedicated to developing syringes, vials and cartridges with the lowest particle generation, reduced or even no extractable release, and a metal-free option. The team is also responsible for the improvement of deep freeze/dead volume properties of Stevanato Group solutions to refine the Vaccine and Gene Therapies application. To deliver superior Process Excellence & Digitalization, the Drug Containment Solutions team is working on different projects, among which, the development of a unique identification and serialization system of individual containers. Finally, the DCS team contributes to the development of Drug Delivery Systems designed around patient-centricity, sustainability and digitalization and provides superior primary packaging fully compatible with the devices under development. The main innovations included in the Drug Containment Solutions portfolio are: ALBA(R) Platform, Integrated Safety System (ISS) and Primary Container Traceability. Stevanato Group has also introduced new sustainability practices as part of its corporate Circular Economy innovation program. In particular, projects

were mobilized to identify alternative materials and processes that provide more sustainable sterilization techniques while maintaining the overall performance of materials post-sterilization cycle. As part of its corporate sustainability innovation program, Stevanato Group launched a sustainable version of secondary packaging for syringes focusing on biopolymers and recycled plastic as well as packaging and process improvements to reduce related emissions and other sustainable measures. Stevanato Group is committed to reducing emissions and the use of fossil resources. The Ready-To-Use drug containers require single-use polymers for the pharmaceutical secondary packaging (Nest and Tub), ensuring sterility and processability. Indeed, a Bio-Circular version of poly-styrene and polypropylene used to produce secondary packaging of syringes was identified. Raw material to produce polymer is obtained from renewably sourced feedstocks derived solely from waste. This reduces the fossil resources consumption and emissions associated with the life cycle of the product while ensuring the same level of quality. The proposed solution is now being tested on one article code and, once proven successful, can be scaled up to the entire RTU product family. Thanks to the ISCC+ certification, rigorous compliance with the mass balance approach is ensured and trust among the different players of the value chain is maintained. In 2022, Stevanato Group also launched a high-end Ready-To-Use (RTU) solution platform with an initial focus on vials, based on the Groups market-leading EZ-fill(R) technology: EZ-fill Smart". The platform offers the market a more environmentally-friendly sterilization method compared to traditional Ethylene Oxide (EtO) sterilization that can result in improved safety. It is intended to improve sustainability and increase the packagings efficiency using biopolymers and recycled plastic. The innovative, fully passive EZ-fill(R) Integrated Safety System is designed to reduce needle-stick injuries and is delivered sterile and ready for filling, enabling pharmaceutical companies to add needlestick protection to their syringe products. In contrast to traditional add-on models in the market, Stevanato Groups Integrated Safety System (ISS) is a simplified, pre-assembled component. Its design promotes sustainable advancements throughout the entire pharma company manufacturing process including: " Fewer materials and parts to purchase (incoming and outcoming), equating to plastic reduction. " Reduced shipping and transport costs (only one shipment of the pre-assembled system is needed), resulting in reduced CO emissions. 2 The Group is also actively collaborating with the scientific community and universities to advance its scientific insight into the Groups current and prospective product line, as well as to provide its customers with the latest know-how on specific products. In certain research areas, including chemical-physical and morphological characterization of glass surfaces and drug interactions, Stevanato Group cooperates with universities such as Ca Foscari University (Venice, Italy), Federico II University (Naples, Italy), the National University of Ireland Mynooth (Ireland), and the University of Trento (Italy). 4.2.2 R&D ON DRUG DELIVERY SYSTEMS (DDS) In addition to the activities related to Drug Containment Solutions, a fundamental responsibility of Biopharma-ceutical and Diagnostic Solutions R&D is the development and expansion of Stevanato Groups Drug Delivery Systems (DDS) portfolio. This includes developing innovative delivery solutions that are focused on usability, safety, performance and manufacturability. The main projects the department is working on include: Alina(R), Aidaptus(R), Stevanato Groups On-Body Delivery System, and ICOcap(R).

Alina(R) is a disposable, multi-use pen injector platform for subcutaneous administration of injectable therapy. The platform is available in variable and fixed-dose versions compatible with established therapeutic regimens as well as innovative drug therapies beyond diabetes and weight management. The project involves multiple Stevanato Group sites and functions and an international design and development team. Aidaptus(R) is an innovative disposable auto-injector offered in collaboration with design and development partner, Owen Mumford, a certified B Corporation. Aidaptus(R) can be especially suitable for pharmaceutical companies for reducing risk during drug development and life cycle management as it accommodates both 1 mL and 2.25 mL syringes with minimal part changes, automatically adapting to different drug fill volumes. The minimal change parts required for the different pre-filled syringes reduces manufacturing complexity, thus, offer sustainability advantages. An added value for patients is that the simple and easy-to-use device allows them to self-administer their therapy. Stevanato Groups On-Body Delivery System is a drug delivery device composed of a reusable controller and a disposable pod with a pre-loaded cartridge. The reusable part extends the lifespan of the product to multiple-uses and reduces product waste for a more sustainable device solution. The device enables controlled self-administration of therapy while reducing unnecessary hospital stays. With the ability to deliver micro-precision basal doses and full-content bolus injections, the On-Body Delivery System is a highly flexible and customizable platform suitable for a wide range of therapies. A number of developments have reduced the systems energy consumption, improving overall efficiency and extending battery lifetime. ICOcap(R) is a capsule-based dry-powder inhaler for the treatment of asthma, chronic obstructive pulmonary disease (COPD) and other respiratory-related diseases. Licensed from inhalation specialist, Iconovo, the device performs similarly to established inhalers on the market while offering improved handling features. The project involves multiple Stevanato Group sites, functions and an international design and development team. The team has improved the manufacturing process by eliminating unnecessary materials and assembly steps and optimizing the molding of components, reducing the scrap rate. 4.2.3 R&D ON ENGINEERING The Engineering department analyzes internal and external expectations in order to clearly guide product development in the following directions: high performance, quality and reliability, and smart and connected equipment. The Engineering quality control systems are designed to ensure that the manufacturing processes, including those of pharma customers and contracted manufacturing companies, comply with Generic Good Practice (GxP) standards based on the Good Automated Manufacturing Practice (GAMP) guidelines issued by the International Society for Pharmaceutical Engineering (ISPE). Each individual piece of machinery/equipment is developed and manufactured as a singular project and ad-hoc project management tools are utilized to manage every stage and minimize risk. Like the Biopharmaceutical and Diagnostic Solutions R&D division, the Engineering division contributes to the three R&D pillars, in particular, to Process Excellence & Digitalization. Below are the main projects under Engineering R&D essential to promoting innovation and increasing Stevanato Groups competitiveness and market share. Smart Factories: The Group has designed its production plants to be highly interconnected.

Digital Twin The customer can review a machines performance and interact virtually with the equipment before going into production. This allows the customer to foresee possible problems and reduce the production time needed based on anticipatory decisions. Inspection Emulator: This product is a virtual simulation of the machine vision inspection process. The overall target is to optimize and develop vision inspection recipes completely off-line. In this way, the development is performed without machine stop time. Vision Robot Unit A robotic human-like inspection unit for inspecting parenterals that allows for flexibility along with the replicability and stability given by automatic equipment. MAVIS platform: it is the latest suite for high performance inspection results. Developed to inspect up to 400 pieces per minute, it matches the market requirements for flexibility, gentle container handling, easy maintenance and control, in a compact footprint. The first arrival of the series, in 2022, is suitable for the inspection of pre-filled syringes. Stevanato Group expects to extend the MAVIS platform by adding to its portfolio in 2023 also a new equipment inspecting multiple container types on the same machine. New SW and HW Platform for Inspection Equipment The Group invested in a new SW platform in 2021 aiming to improve performance and increase customer satisfaction. Lines development improvements Stevanato Group is developing new lines with the purpose of reducing capital expenditures and industrial costs, increasing productivity and improving in-line quality control. Assembly | ColleQX data collection tool: ColleQX was developed in cooperation with a pharmaceutical company to create the best solution for data collection and analysis. The enhanced quality of data can help shed light on essential preventive maintenance activities and performance improvements.

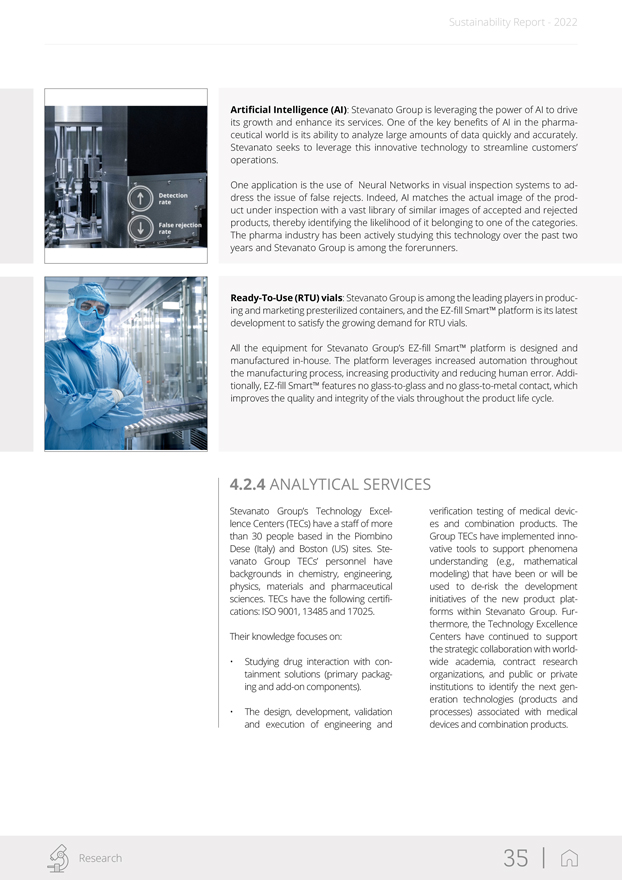

Artificial Intelligence (AI): Stevanato Group is leveraging the power of AI to drive its growth and enhance its services. One of the key benefits of AI in the pharmaceutical world is its ability to analyze large amounts of data quickly and accurately. Stevanato seeks to leverage this innovative technology to streamline customers operations. One application is the use of Neural Networks in visual inspection systems to address the issue of false rejects. Indeed, AI matches the actual image of the product under inspection with a vast library of similar images of accepted and rejected products, thereby identifying the likelihood of it belonging to one of the categories. The pharma industry has been actively studying this technology over the past two years and Stevanato Group is among the forerunners. Ready-To-Use (RTU) vials: Stevanato Group is among the leading players in producing and marketing presterilized containers, and the EZ-fill Smart" platform is its latest development to satisfy the growing demand for RTU vials. All the equipment for Stevanato Groups EZ-fill Smart" platform is designed and manufactured in-house. The platform leverages increased automation throughout the manufacturing process, increasing productivity and reducing human error. Additionally, EZ-fill Smart" features no glass-to-glass and no glass-to-metal contact, which improves the quality and integrity of the vials throughout the product life cycle. 4.2.4 ANALYTICAL SERVICES Stevanato Groups Technology Excellence Centers (TECs) have a staff of more than 30 people based in the Piombino Dese (Italy) and Boston (US) sites. Stevanato Group TECs personnel have backgrounds in chemistry, engineering, physics, materials and pharmaceutical sciences. TECs have the following certifications: ISO 9001, 13485 and 17025. Their knowledge focuses on: " Studying drug interaction with containment solutions (primary packaging and add-on components). " The design, development, validation and execution of engineering and verification testing of medical devices and combination products. The Group TECs have implemented innovative tools to support phenomena understanding (e.g., mathematical modeling) that have been or will be used to de-risk the development initiatives of the new product platforms within Stevanato Group. Furthermore, the Technology Excellence Centers have continued to support the strategic collaboration with worldwide academia, contract research organizations, and public or private institutions to identify the next generation technologies (products and processes) associated with medical devices and combination products.

As a commitment to the production of high-quality products, Stevanato has adopted a Group Quality Policy which aims to collaborate with its customers throughout the life cycle of their products, from concept development to commercialization and post-sales support. The policy reflects the Groups dedication to delivering high-quality products, advanced technologies and services that fulfill and anticipate its customers needs and ISCC+ certification requirements while ensuring the chain of custody in the processing of sustainable materials along the value chain. 4.3 Product quality and responsibility The Group is committed to creating high-quality systems, processes and services that enhance the integrity of medicines. To ensure product quality, Stevanato Group meets the following certification standards: " ISO 15378 Primary packaging material for medicine products this certification is effective for Nuova Ompi (Padua and Latina), Medical Glass, Ompi North America, Ompi of China, Ompi do Brasil and Balda Germany. " ISO 13485 Medical devices quality management systems this certification is effective for Nuova Ompi (Padua), Balda Germany and Balda USA, Stevanato Group Lab Analytics and US TEC. " ISO 9001 Quality management systems this certification is effective for Nuova Ompi (Padua and Latina), Medical Glass, Ompi North America, Ompi of China, Ompi do Brasil, Balda Germany, Balda USA, Spami, Stevana-to Group Lab Analytics and US TEC. " ISO 17025 General requirements of competence for testing and calibration laboratories, effective for Stevanato Group Lab Analytics. " International Sustainability and Carbon Certification (ISCC+) for Nuova Ompi (Padua) and Bal-da Germany. ISCC+ is a globally recognized certification system for recycled and bio-circular materials that ensures compliance with social and environmental sustainability criteria. To ensure this, checks are carried out at every point in a supply chain to establish integrity and clear evidence of sustainable materials. The achievement of this certification is an important step in enhancing our product portfolio as the Group broadens its sustainable development practices. The ISCC+ certification at Stevanato Groups German and Italian sites (Balda Medical and Nuova Ompi) is the first step of a long-term roadmap that will lead to regenerative business innovation at Stevanato Group while strengthening its positioning in the market. Everyone in Stevanato Group, from senior management to individual employees, is accountable and strives to ensure the continuous improvement and effectiveness of Stevanato Group Quality Management System and Stevanato Group Quality Policy in order to maximize the quality and integrity of the Groups products. Drug containment, diagnostic and delivery solutions often came from years of collaboration with customers to develop the optimal method for containing a drug product and delivering it to the patient community. The customized solutions provided vary depending on the characteristics and chemical composition of the pharmaceutical products, logistical needs (e.g., transport and shelf-life), factors such as the designated patient community (including, potentially, the geographic location), and specific regulatory requirements. The containment and delivery solution provided is an integral component of the drug product itself and part of the regulatory filings required to approve drug product marketing and commercialization. Hence, the quality and dependability of drug containment and delivery solutions is critical to obtaining commercialization and marketing approval from regulatory agencies. As a result, it is often the case that drug product containment and delivery solutions cannot be changed without amending the regulatory filings that have been specifically approved by the relevant regulatory agency. During 2022, there were no incidents of non-compliance with regulations and/or voluntary codes concerning the health and safety impacts of products and services.

5 Attention to Human Capital

Values and Guiding Principles are the cornerstone of harmonious interactions at Stevanato Group and the roots of our leadership in excellence. We foster a culture that respects Diversity, Equity & Inclusion and encourages individual contributions, rewarding merit and measurable achievements. The Groups policies focus on ensuring fair treatment in terms of compensation, benefits and career development and embrace gender diversity as a first step of the journey. 5.1 Stevanato Groups human resources Stevanato Groups HR strategy endeavors to build a strong team and foster the Groups sustainable growth through several key areas of intervention: " Talent acquisition: Attracting talent through competitive offers in terms of career and self-development for all candidates, while ensuring fairness and inclusivity in the selection process. " Talent management: Offering paths to learning and development that nurture and retain talent as well as support the Groups growth. Training courses that bolster technical, managerial and organizational skills for employees continuous improvement and tools that assess employee performance help individuals constantly evolve and pursue their personal objectives. " Total reward: Implementing clear policies to reward merit and measurable achievements in a transparent, equal and fair way. " Engagement and culture: Disseminating Stevanato Groups corporate culture, starting from the company Values and Guiding Principles, and focusing on customer-centricity, quality mindset, safety and diversity. " Diversity, Equity and Inclusion: Promoting a social environment that creates a sense of belonging and values diversity at all levels and locations. This consists of inclusion policies, diversity management plans and equal opportunities (including equal pay for equal roles), as well as monitoring and elevating KPI diversity targets. " Employee well-being: Advancing welfare programs that support employee well-being and work-life balance including initiatives in favor of work flexibility (working hours, smart working, etc.), as well as physical and mental health support plans. The Group is guided by legislation and international principles and is committed to maintaining a climate of trust and respect which promotes inclusion and team spirit. The Code of Ethics sets out the standards of conduct identified by the Group. All stakeholders shall respect the Guidelines which represent Stevana-tos pillars of business, among which: legality, fairness, anti-discrimination, professionalism, transparency, market abuse prevention, diligence and commitment in daily work execution, corruption prevention, privacy, health and safety, integrity, sustainability and environmental safety. As a multinational organization, the Group manages people of different nationalities, genders and cultures who work together in a climate of mutual respect. The objective is to promote an inclusive approach that encourages creativity and innovation, contributing to the development of multicultural human capital with different backgrounds and characteristics. A positive work climate at all Group facilities is ensured through dialogue and the sharing of opinions and ideas. The Company offers the possibility of membership in trade unions and the right to collective bargaining in compliance with respect for human rights and diversity. It also adheres to

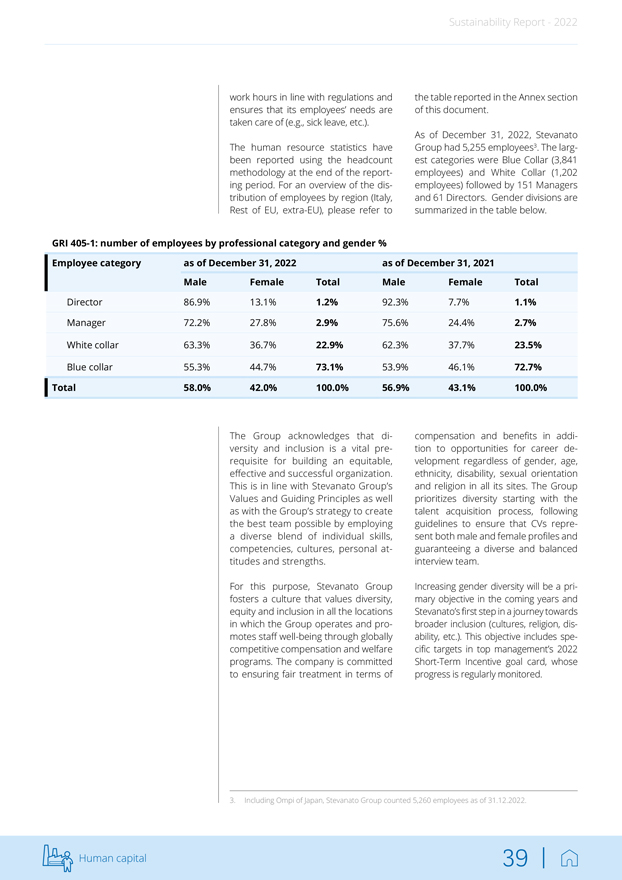

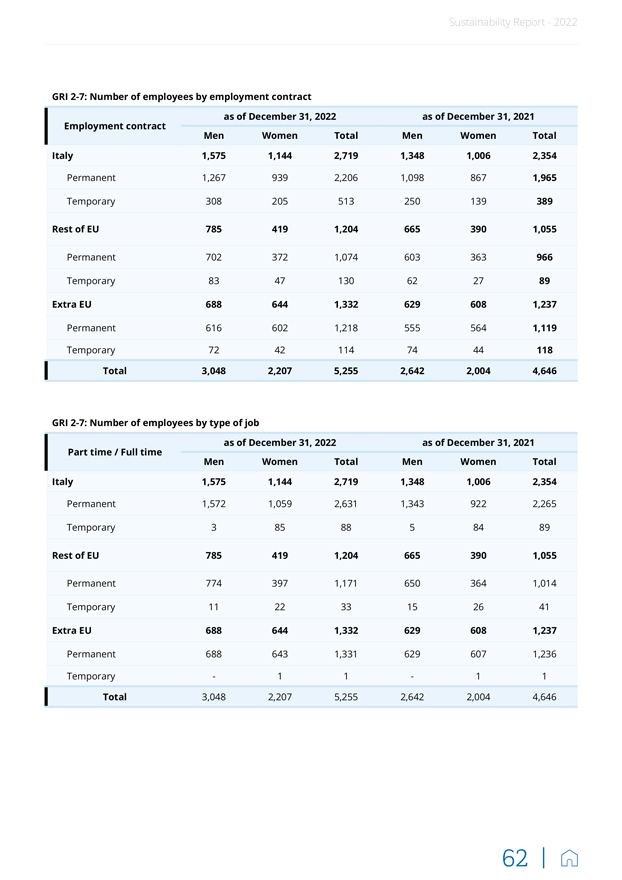

work hours in line with regulations and ensures that its employees needs are taken care of (e.g., sick leave, etc.). The human resource statistics have been reported using the headcount methodology at the end of the reporting period. For an overview of the distribution of employees by region (Italy, Rest of EU, extra-EU), please refer to the table reported in the Annex section of this document. As of December 31, 2022, Stevanato Group had 5,255 employees3. The largest categories were Blue Collar (3,841 employees) and White Collar (1,202 employees) followed by 151 Managers and 61 Directors. Gender divisions are summarized in the table below. GRI 405-1: number of employees by professional category and gender % Employee category as of December 31, 2022 as of December 31, 2021 Male Female Total Male Female Total Director 86.9% 13.1% 1.2% 92.3% 7.7% 1.1% Manager 72.2% 27.8% 2.9% 75.6% 24.4% 2.7% White collar 63.3% 36.7% 22.9% 62.3% 37.7% 23.5% Blue collar 55.3% 44.7% 73.1% 53.9% 46.1% 72.7% Total 58.0% 42.0% 100.0% 56.9% 43.1% 100.0% The Group acknowledges that diversity and inclusion is a vital prerequisite for building an equitable, effective and successful organization. This is in line with Stevanato Groups Values and Guiding Principles as well as with the Groups strategy to create the best team possible by employing a diverse blend of individual skills, competencies, cultures, personal attitudes and strengths. For this purpose, Stevanato Group fosters a culture that values diversity, equity and inclusion in all the locations in which the Group operates and promotes staff well-being through globally competitive compensation and welfare programs. The company is committed to ensuring fair treatment in terms of compensation and benefits in addition to opportunities for career development regardless of gender, age, ethnicity, disability, sexual orientation and religion in all its sites. The Group prioritizes diversity starting with the talent acquisition process, following guidelines to ensure that CVs represent both male and female profiles and guaranteeing a diverse and balanced interview team. Increasing gender diversity will be a primary objective in the coming years and Stevanatos first step in a journey towards broader inclusion (cultures, religion, disability, etc.). This objective includes specific targets in top managements 2022 Short-Term Incentive goal card, whose progress is regularly monitored. 3. Including Ompi of Japan, Stevanato Group counted 5,260 employees as of 31.12.2022.

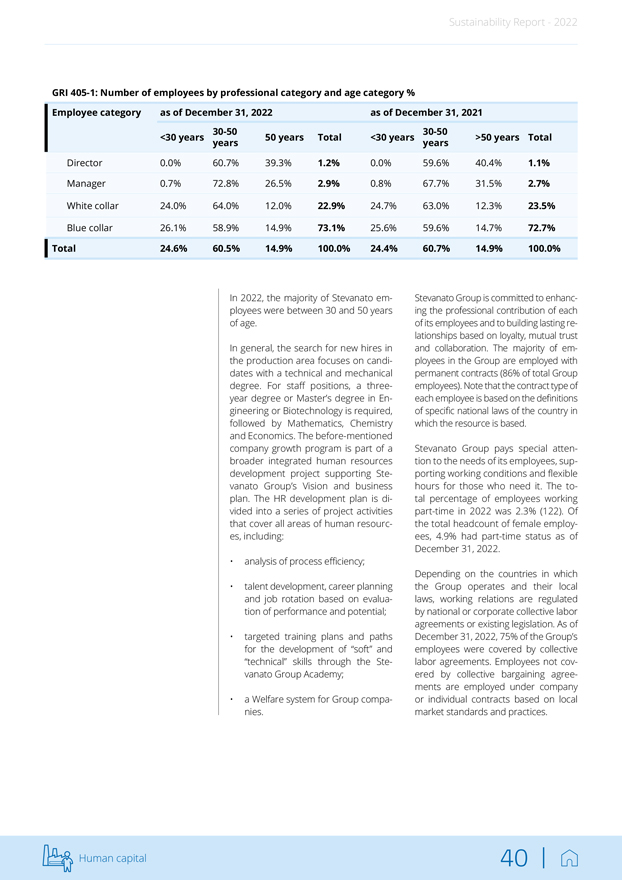

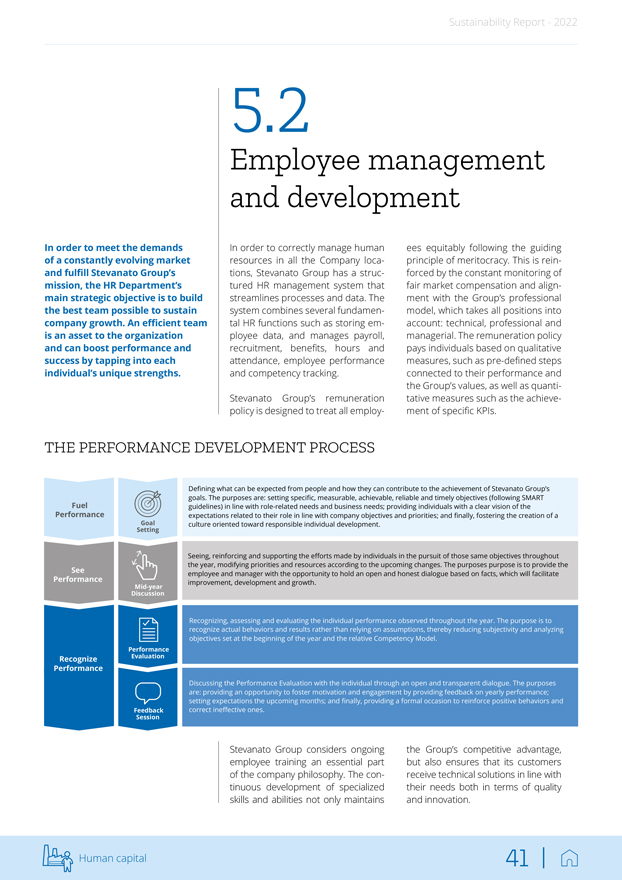

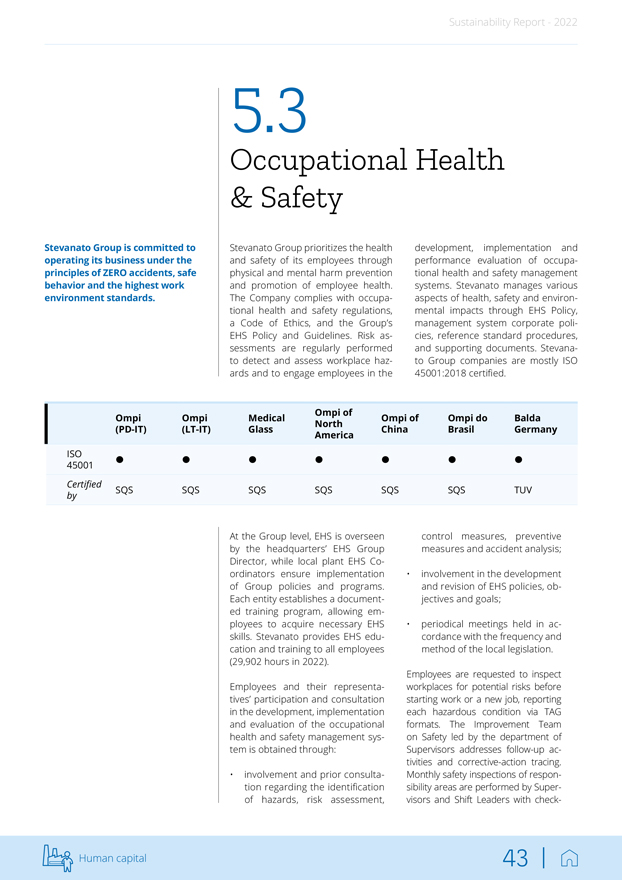

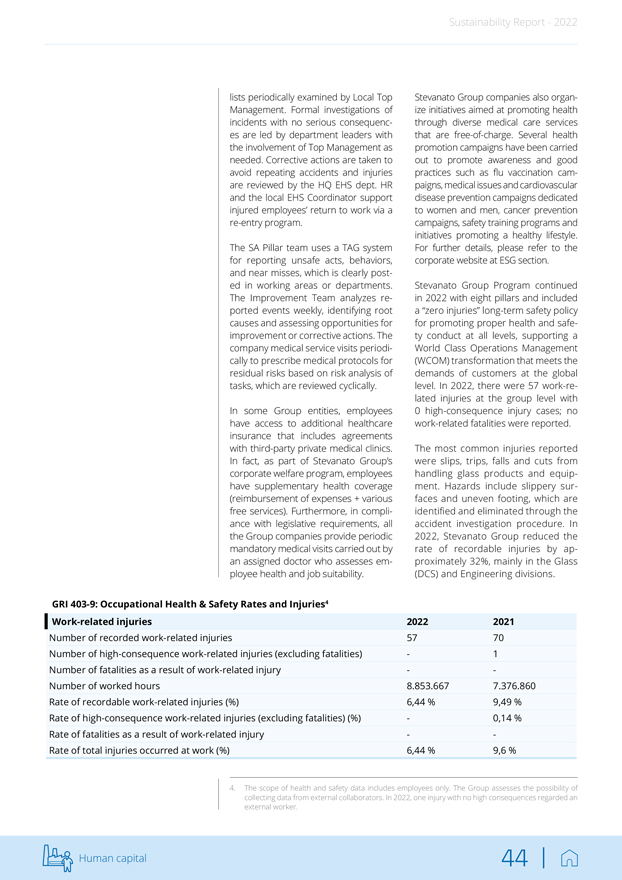

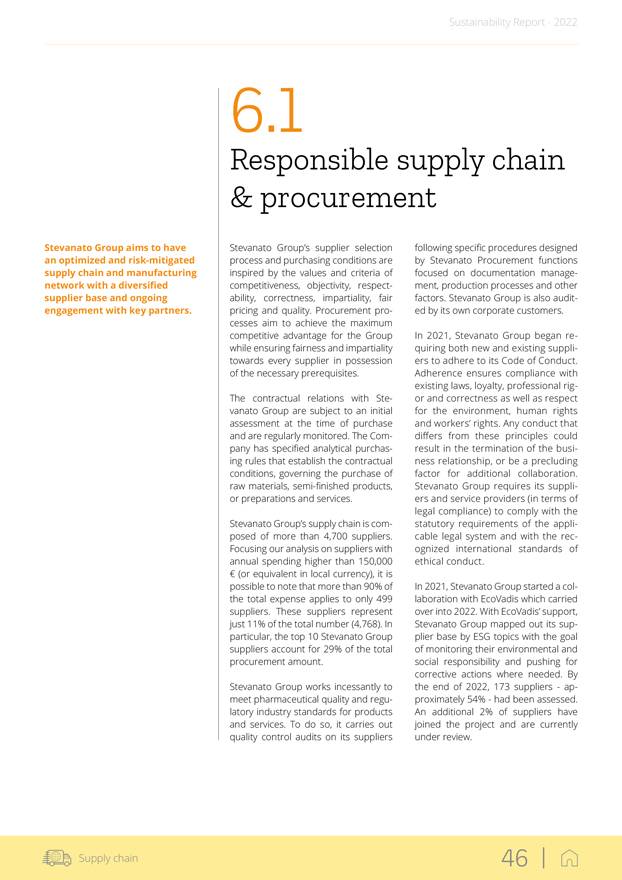

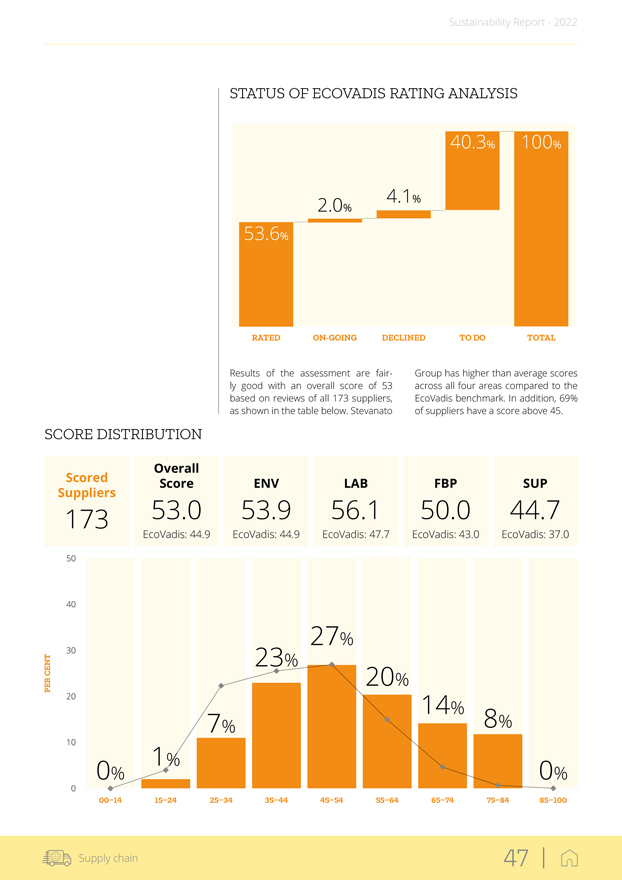

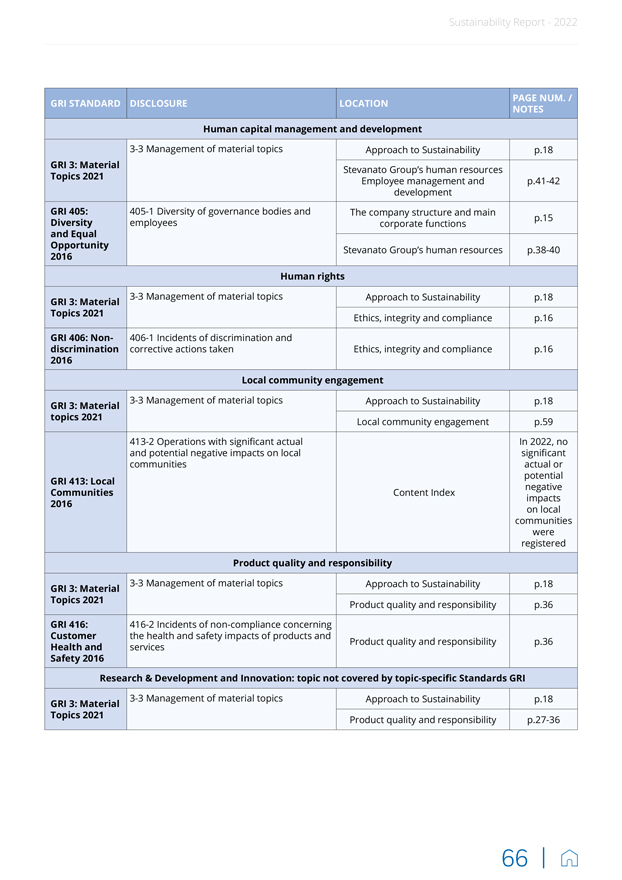

GRI 405-1: Number of employees by professional category and age category % Employee category as of December 31, 2022 as of December 31, 2021 30-50 30-50 <30 years 50 years Total <30 years >50 years Total years years Director 0.0% 60.7% 39.3% 1.2% 0.0% 59.6% 40.4% 1.1% Manager 0.7% 72.8% 26.5% 2.9% 0.8% 67.7% 31.5% 2.7% White collar 24.0% 64.0% 12.0% 22.9% 24.7% 63.0% 12.3% 23.5% Blue collar 26.1% 58.9% 14.9% 73.1% 25.6% 59.6% 14.7% 72.7% Total 24.6% 60.5% 14.9% 100.0% 24.4% 60.7% 14.9% 100.0% In 2022, the majority of Stevanato employees were between 30 and 50 years of age. In general, the search for new hires in the production area focuses on candidates with a technical and mechanical degree. For staff positions, a three-year degree or Masters degree in Engineering or Biotechnology is required, followed by Mathematics, Chemistry and Economics. The before-mentioned company growth program is part of a broader integrated human resources development project supporting Stevanato Groups Vision and business plan. The HR development plan is divided into a series of project activities that cover all areas of human resources, including: " analysis of process efficiency; " talent development, career planning and job rotation based on evaluation of performance and potential; " targeted training plans and paths for the development of soft and technical skills through the Stevanato Group Academy; " a Welfare system for Group companies. Stevanato Group is committed to enhancing the professional contribution of each of its employees and to building lasting relationships based on loyalty, mutual trust and collaboration. The majority of employees in the Group are employed with permanent contracts (86% of total Group employees). Note that the contract type of each employee is based on the definitions of specific national laws of the country in which the resource is based. Stevanato Group pays special attention to the needs of its employees, supporting working conditions and flexible hours for those who need it. The total percentage of employees working part-time in 2022 was 2.3% (122). Of the total headcount of female employees, 4.9% had part-time status as of December 31, 2022. Depending on the countries in which the Group operates and their local laws, working relations are regulated by national or corporate collective labor agreements or existing legislation. As of December 31, 2022, 75% of the Groups employees were covered by collective labor agreements. Employees not covered by collective bargaining agreements are employed under company or individual contracts based on local market standards and practices.